What Are Cast Iron Castings? Applications, Types & Benefits Explained

If you’ve ever handled a machine part, a valve body, or even a simple fitting, you’ve already held a story shaped by molten metal. And when you dig a little deeper, you’ll notice that Cast Iron Castings quietly support most industries around us. Today, let’s walk through this topic together — not as a lecture, but as a simple conversation where you and I figure things out step by step.

Across our sector, we work with people who care about precision. People like you — who want components that don’t quit, don’t crack, and don’t surprise you at the wrong time. So let’s explore this topic from your perspective.

So, What Are Cast Iron Castings Really?

Cast Iron Castings are cast iron components formed by melting the metal and pouring it into a mould. That’s the simple version.

The real magic happens when the metal cools inside that mould. It takes shape, gains strength, and turns into something your system depends on every day.

Cast iron behaves differently from steel. It flows well. It forms complex shapes easily. And it gives you durability without forcing you to stretch your budget.

That’s why many industries still trust it — not out of habit, but because it works.

Your Material Choices: Cast Iron, Cast Steel, or Stainless Steel

When you think about castings, you’re really choosing materials that match your application. Let’s keep this simple.

Cast Iron Castings

If you need stability, long life, and value for money, you choose cast iron. It handles pressure, weight, and slow movement beautifully.

Cast Iron steel Castings / Cast Steel Castings

This option suits you when your equipment faces impact, vibration, or sudden loads. Cast iron steel castings are tougher and more resilient.

Stainless Steel Castings

Go for this when you’re dealing with moisture, chemicals, heat, or corrosion. If your environment is harsh, stainless steel protects your investment.

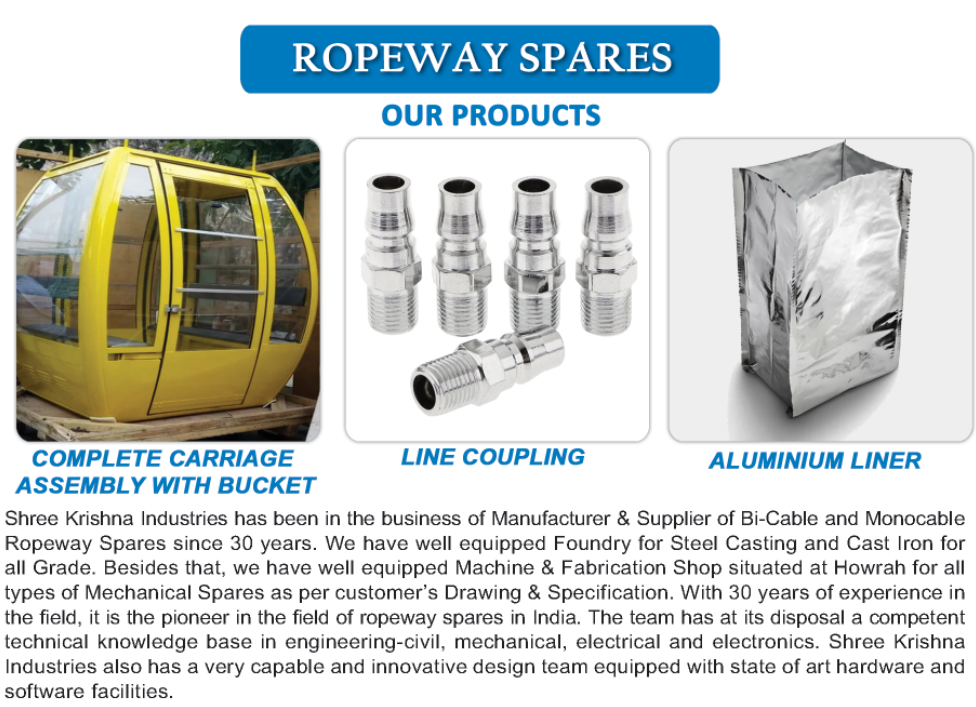

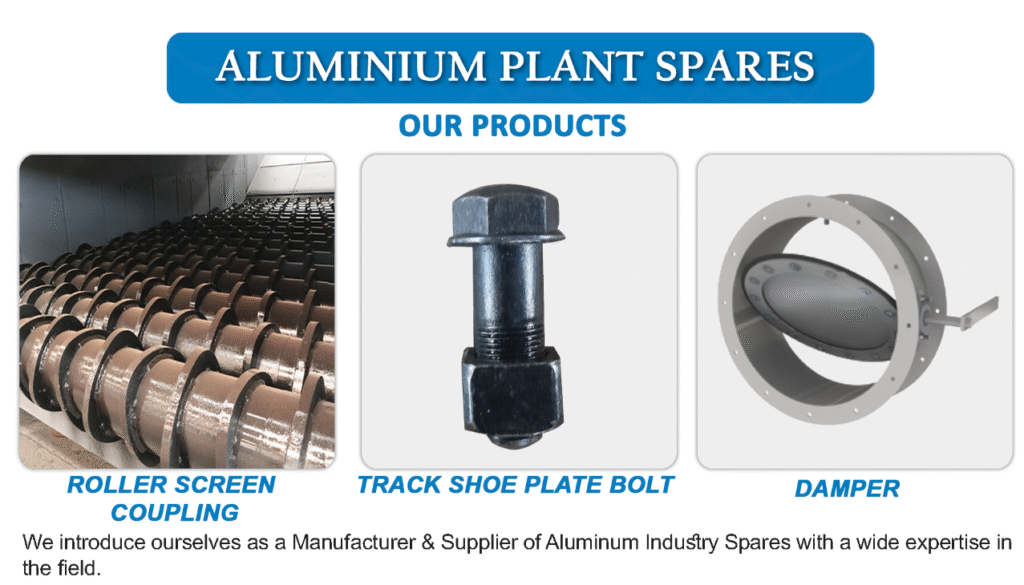

At Shree Krishna Industries, we offer all three because every project — including yours — carries its own challenges.

Where You’ll See Cast Iron Castings in Real Life

You’d be surprised how many places rely on cast iron components.

Here are a few that might sound familiar:

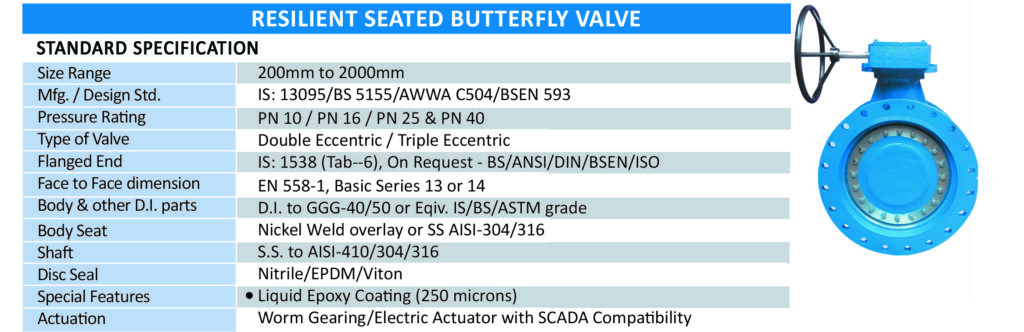

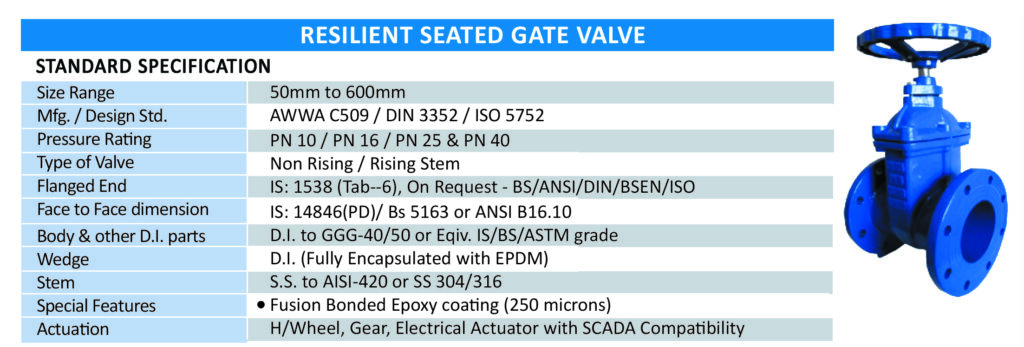

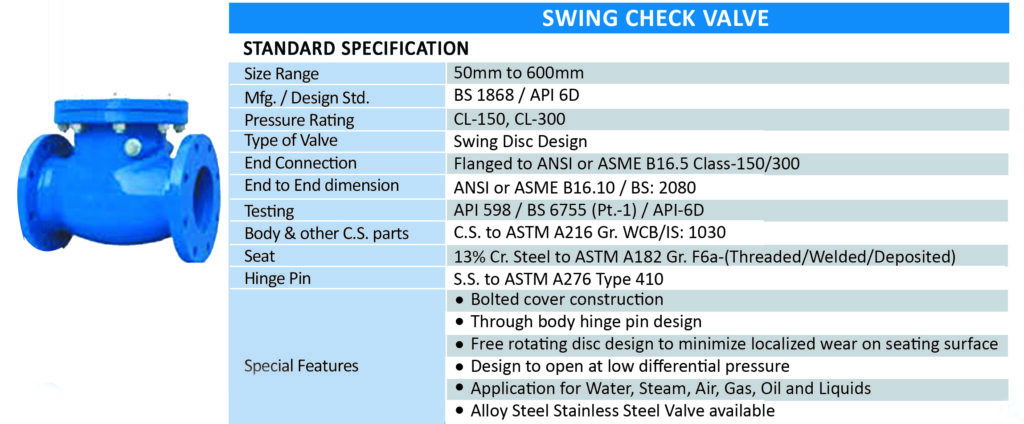

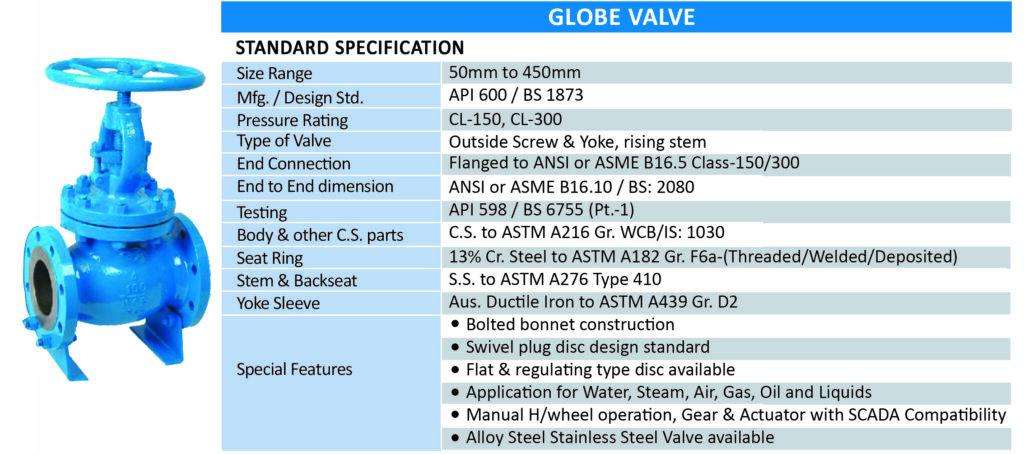

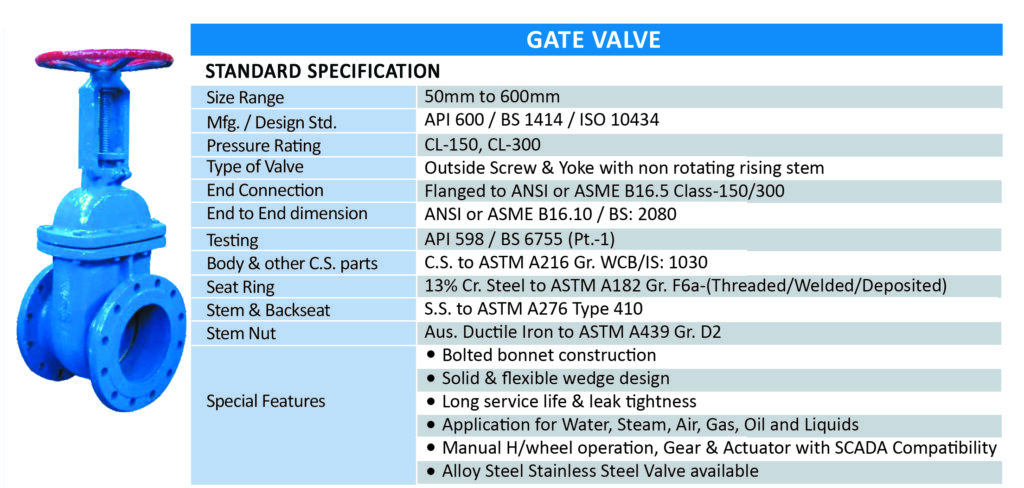

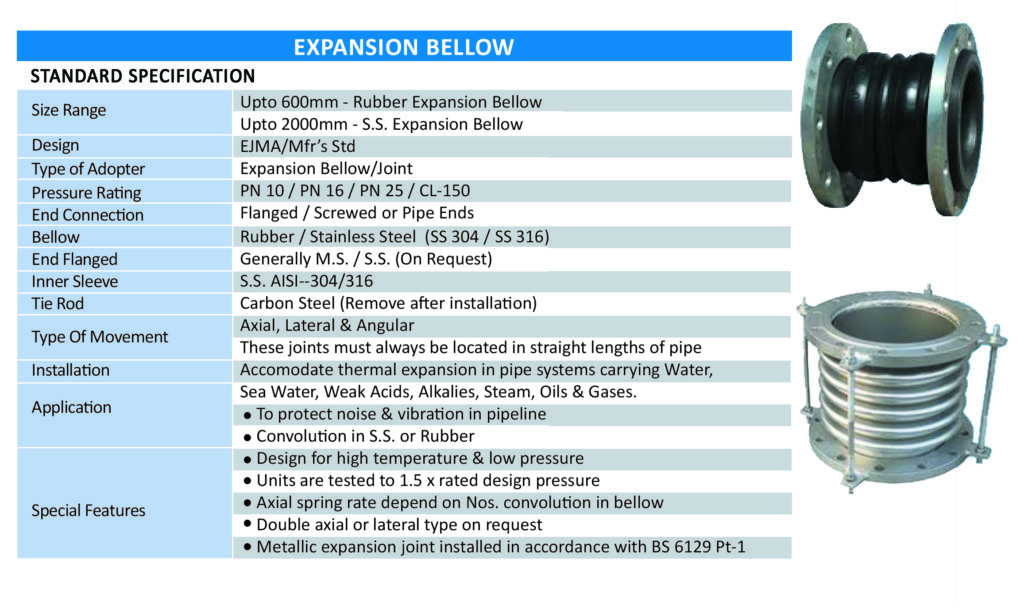

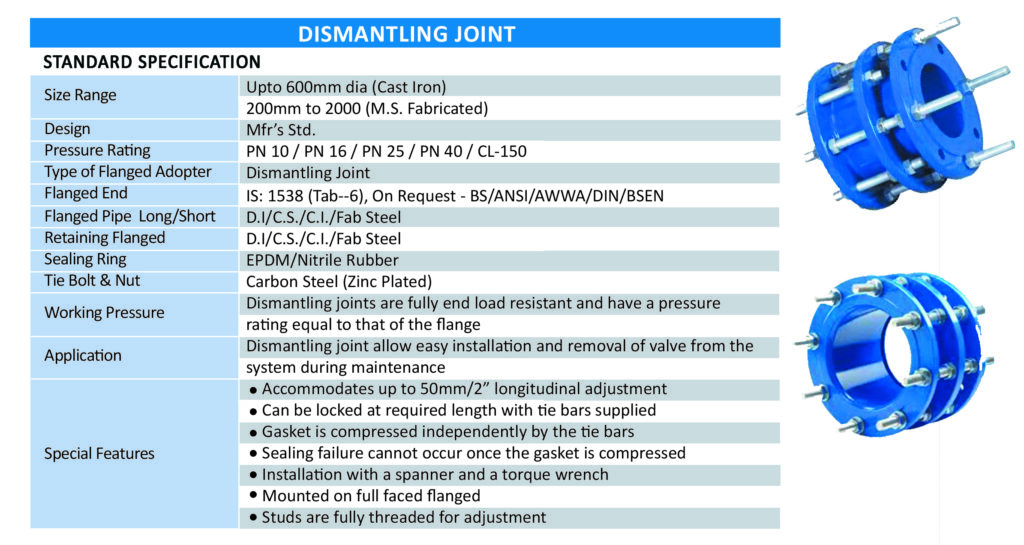

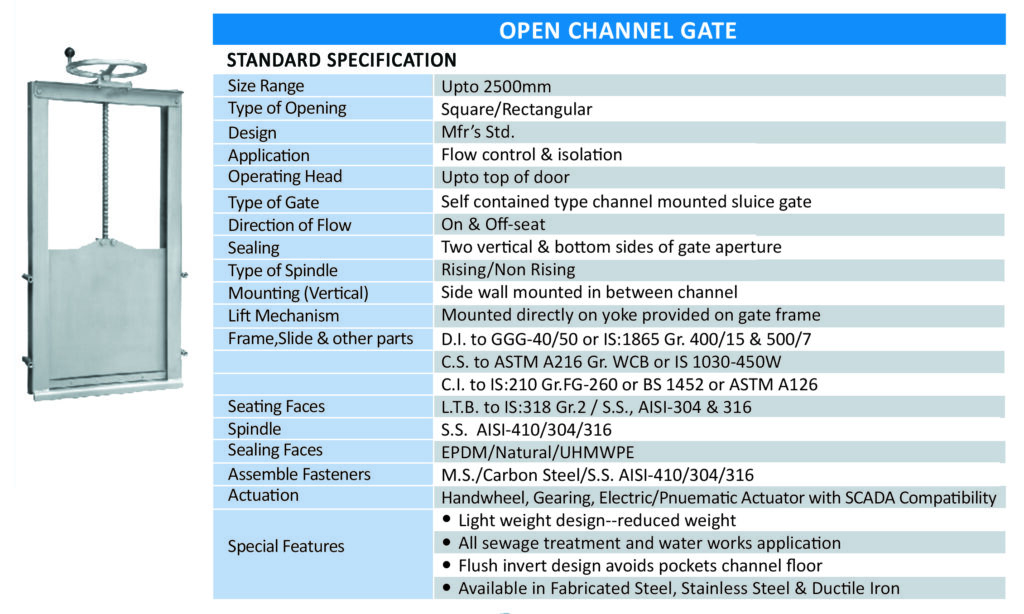

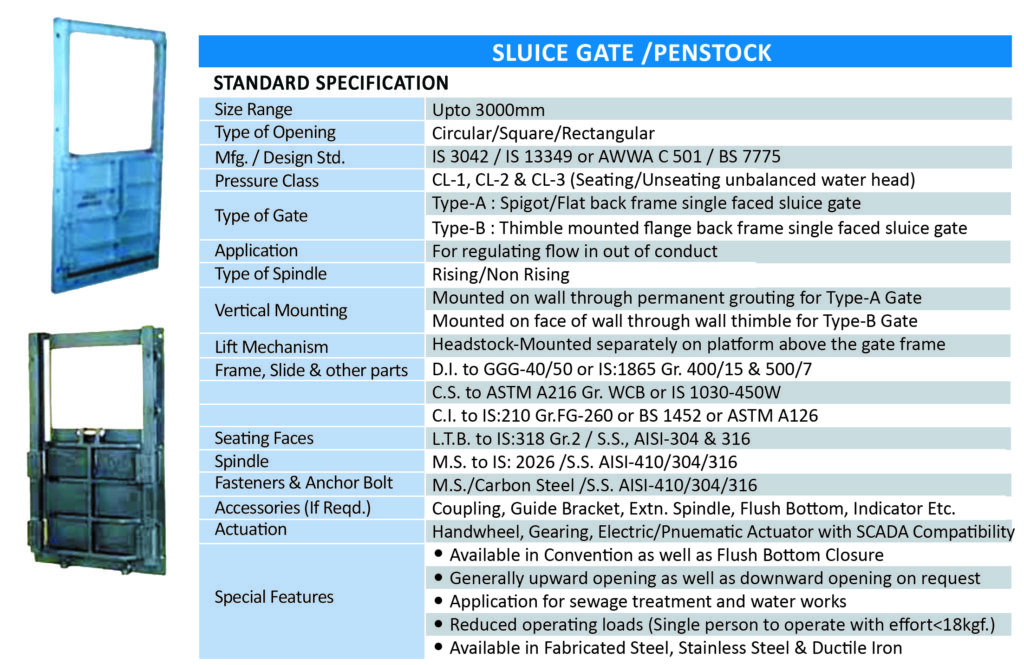

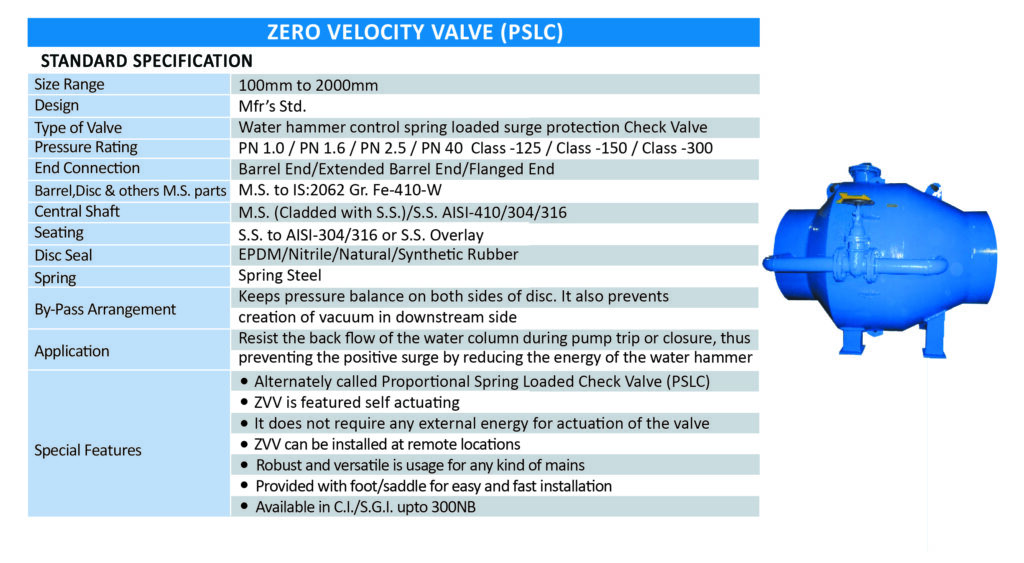

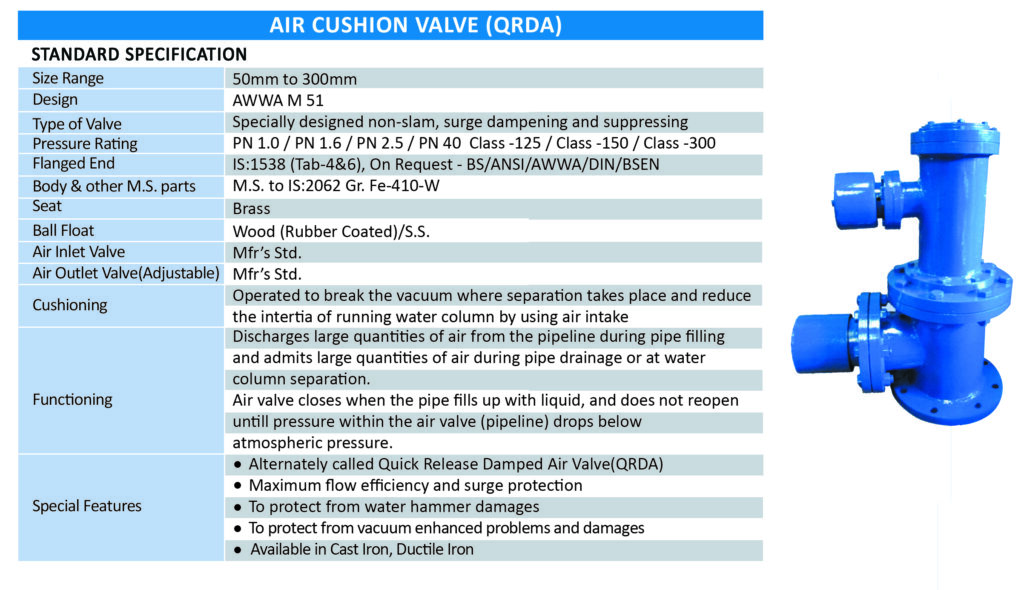

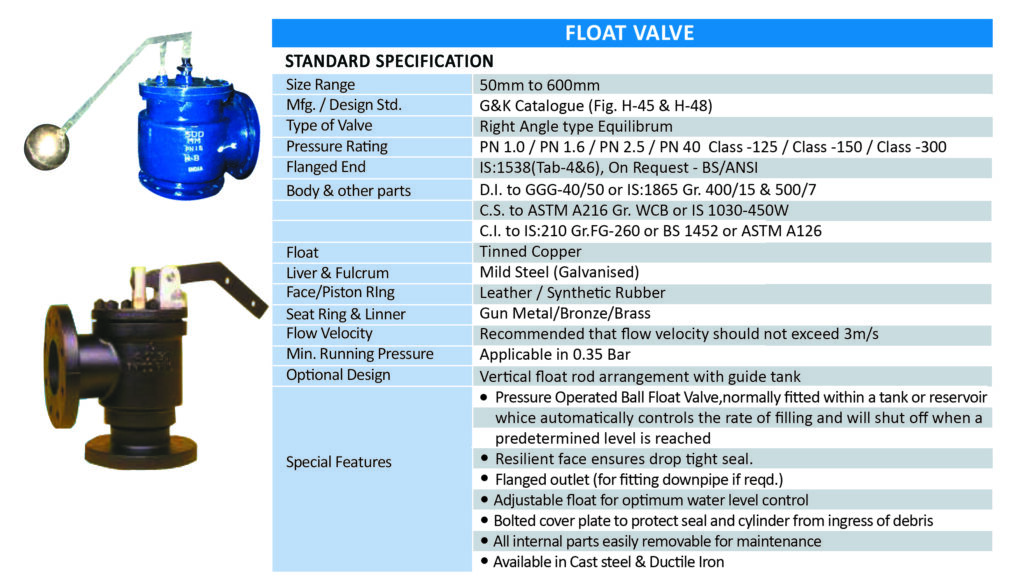

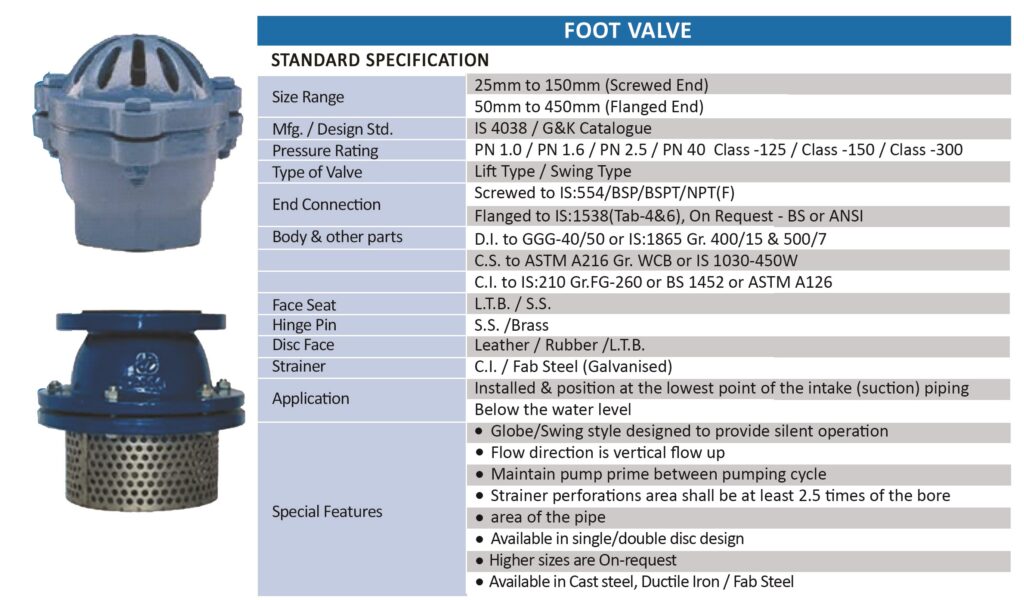

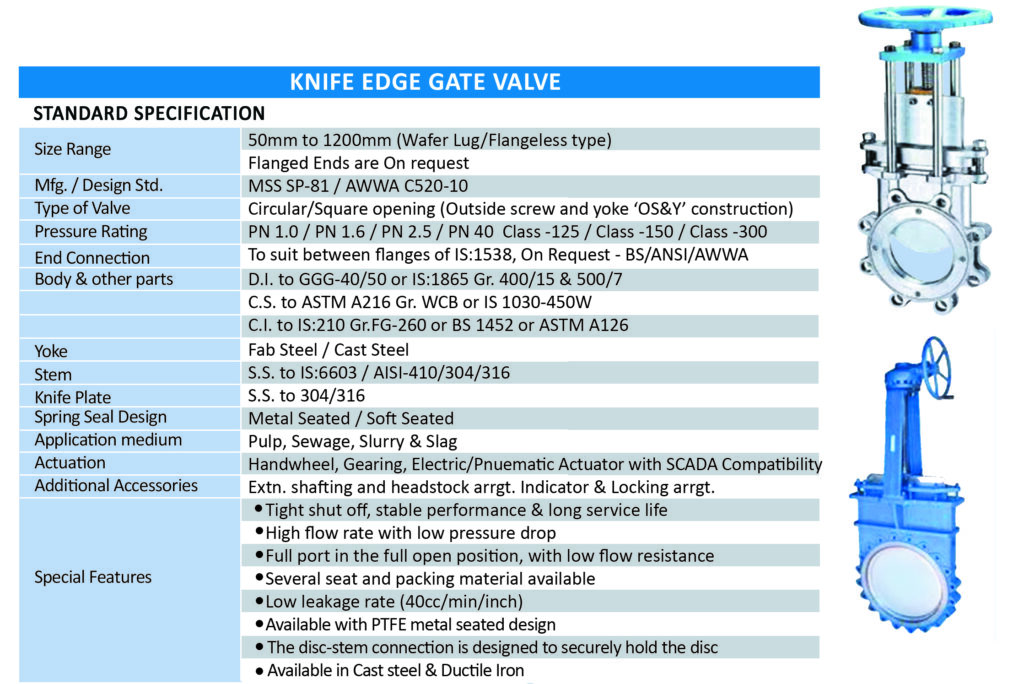

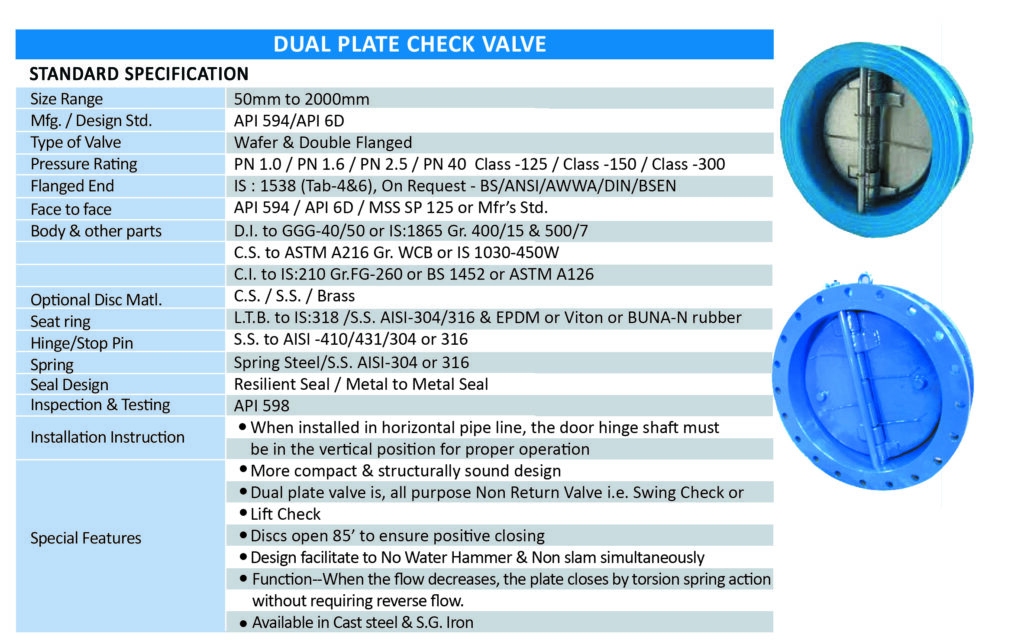

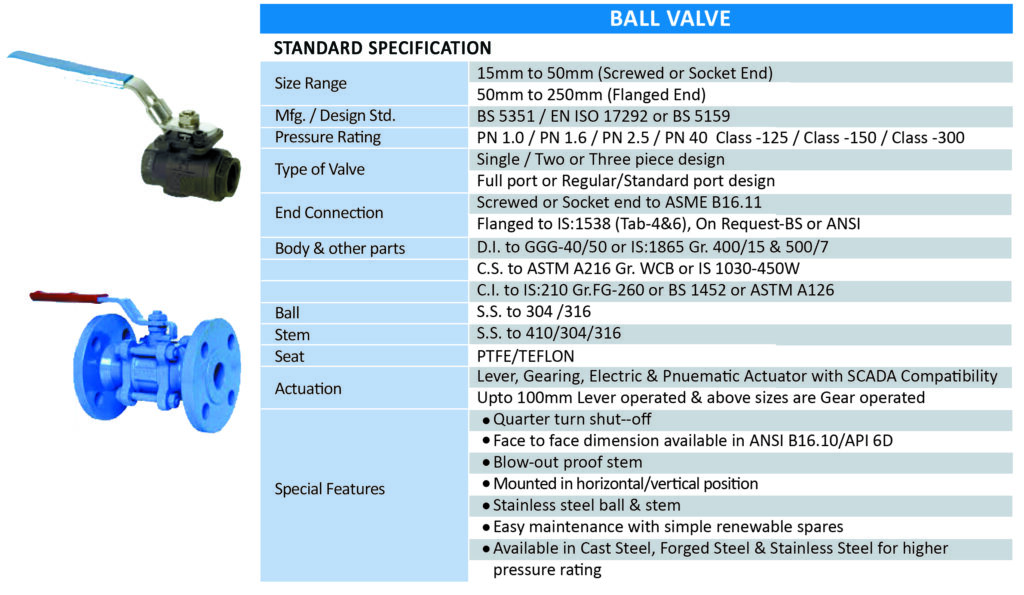

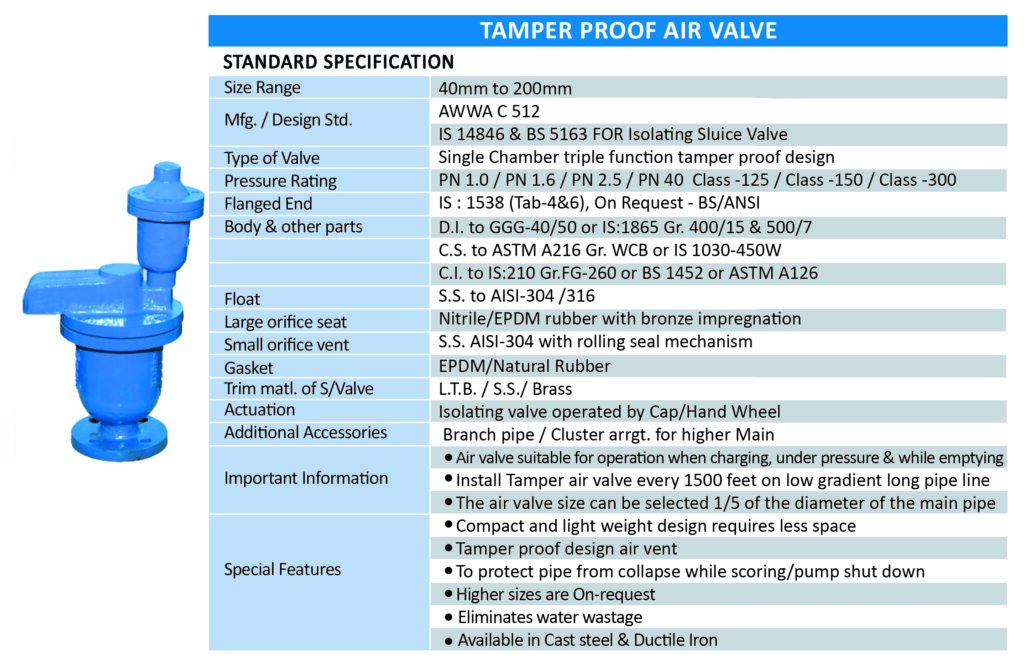

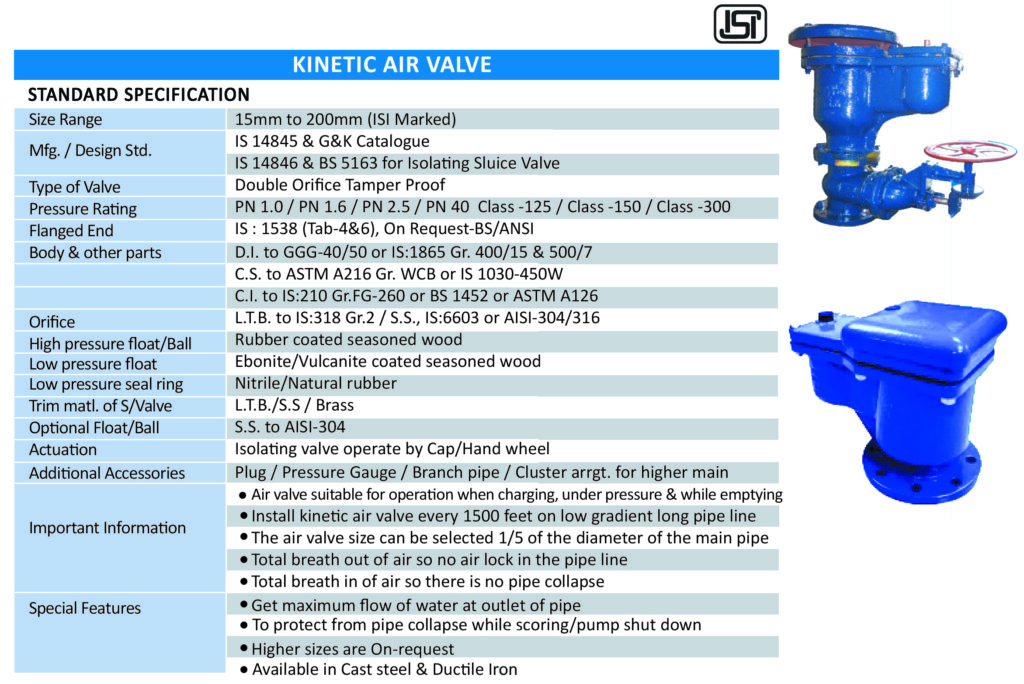

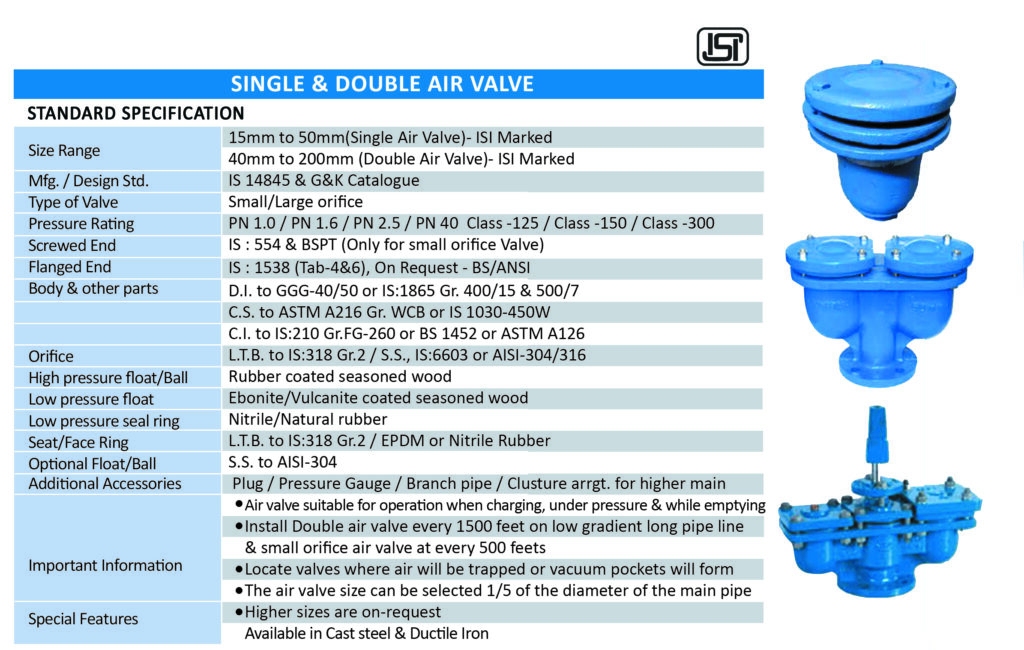

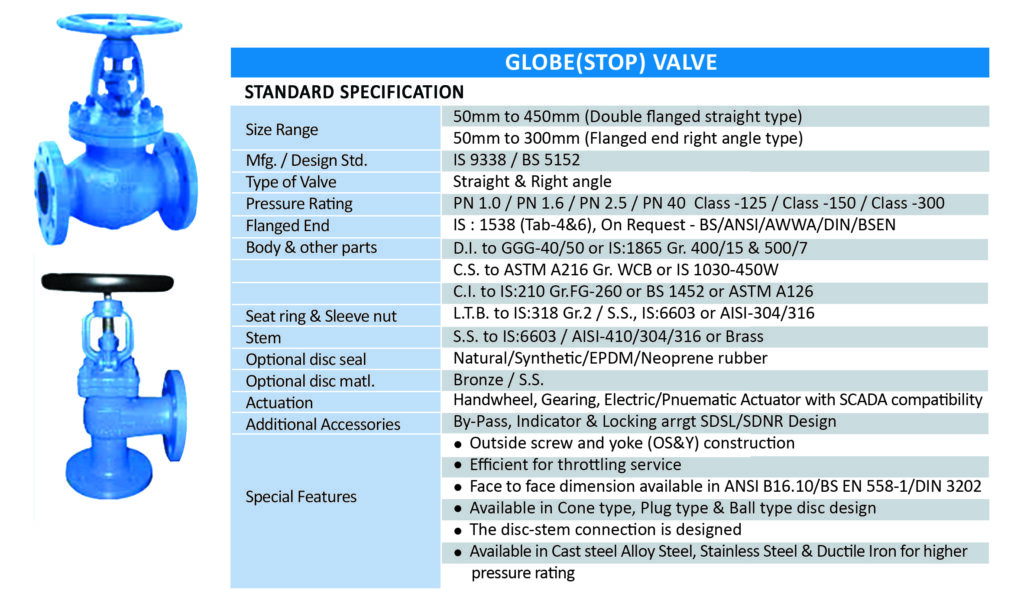

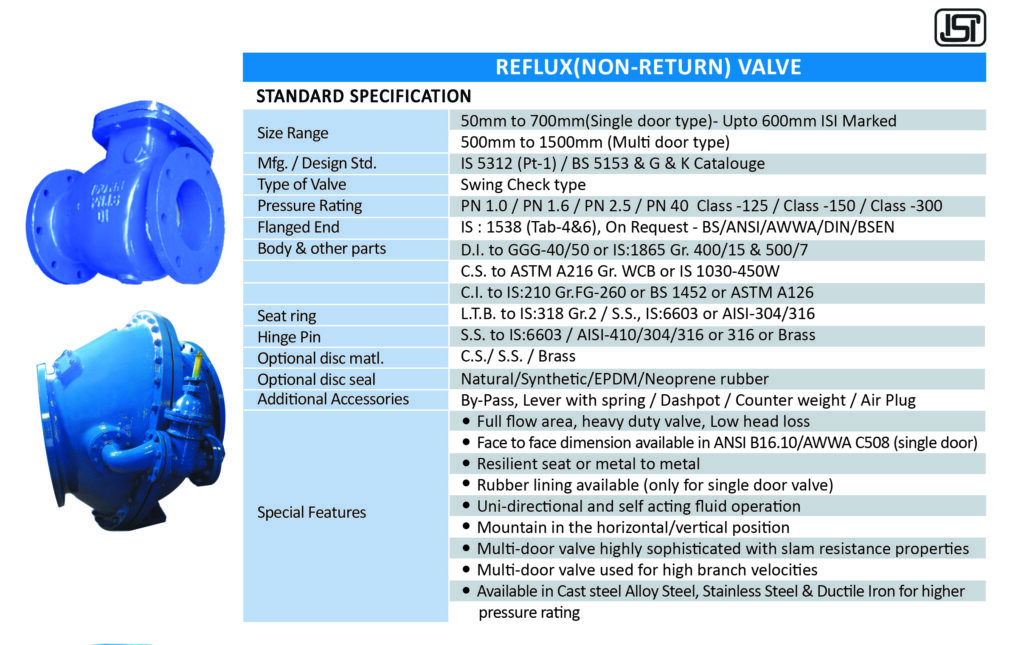

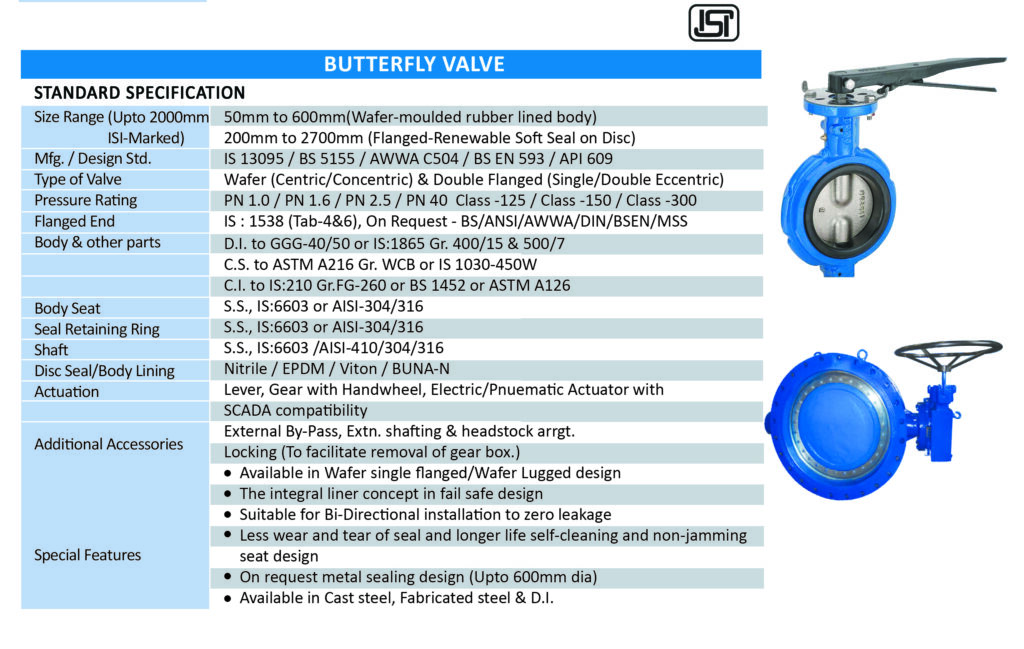

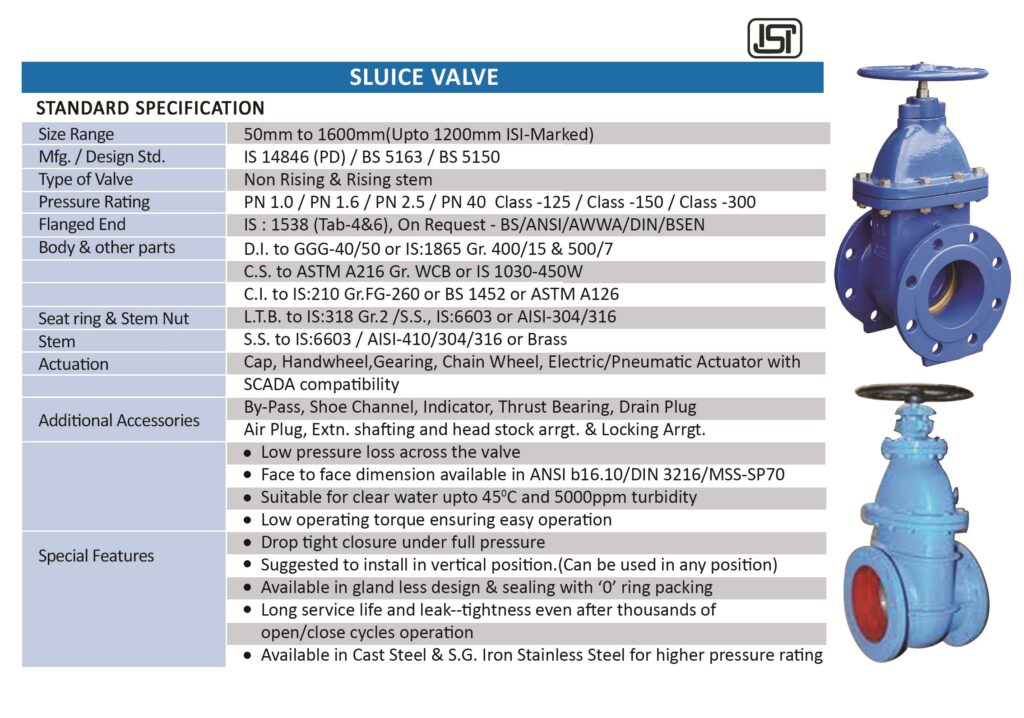

- The valve body that controls flow in your pipeline

- Pump housings that run day after day without drama

- Gear boxes, machine frames, and heavy housings

- Construction hardware like manhole lids, flanges, and fittings

Anywhere you need strength without unnecessary cost, cast iron castings find their place.

And when conditions get tougher, we guide you toward steel or stainless steel alternatives. Because your equipment deserves the right material, not the convenient one

Why Cast Iron Castings Work So Well for So Many People

There’s a reason cast iron still holds its ground even with modern alloys crowding the market. You get:

- Reliable performance under static or slow-moving loads

- Excellent wear resistance for long-term setups

- Lower cost compared with many other alloys

- High castability, meaning complex shapes are possible

- Dimensional stability, which keeps your system safe

These advantages matter when your job depends on consistency, not complexity.

How We Create Cast Iron Castings at Our Manufacturing Space

We want your parts to speak for themselves, so we invested in everything under one roof.

- A full-scale foundry that handles Cast Iron, steel, and stainless steel

- A pattern shop where your ideas turn into workable moulds

- Coating, fabrication, and finishing areas that prepare your parts for the field

- A machining unit that shapes raw castings into precise components

- A quality lab that inspects every phase

Our certifications — ISO 9001, 14001, 45001, and BIS approvals — reinforce our promise. But what really matters is this:

We don’t send anything out unless we’d use it ourselves.

Why Working With Us Makes Your Process Smoother

When you trust a casting supplier, you’re really trusting them with your entire project timeline. That’s why we focus on ease, transparency, and precision.

You get:

- A complete casting ecosystem

- Material choices based on your environment

- Custom patterns tailored to your drawings

- Accurate machining for ready-to-fit components

- Consistent delivery timelines

- A team that listens before it suggests

We want your project to feel supported — not just supplied.

Cast Iron Castings vs Stainless Steel Castings — How You Decide

Sometimes you might stand between two options. Here’s a simple guide:

Your Requirement | Choose Cast Iron Casting | Choose Stainless Steel Casting |

You need a long life at a reasonable price | Yes | |

Your environment stays dry and stable | Yes | |

You want corrosion resistance | Yes | |

You work with chemicals or water exposure | Yes | |

You need toughness and vibration resistance | Moderate | High |

If you’re unsure, just share your application, and we’ll guide you.

Conclusion

Cast Iron Castings remain a backbone of the industry. Whether you are building pipelines, pumping systems, valves, infrastructure supports, or heavy machinery, you will often find cast iron castings doing reliable duty. But as demands rise — for strength, durability, and corrosion resistance — cast carbon steel or stainless steel castings become vital.

At Shree Krishna Industries, we understand this spectrum of needs. We believe in giving you a choice: right material, right process, right finishing. When you choose us, you don’t compromise. You get quality, customisation, compliance, delivery — and peace of mind.

So next time you plan a project — small or large — think about what your components need. Then connect with us. Let’s build something strong together.

FAQs

1. Will cast-iron items work well under pressure?

They handle steady pressure well. For aggressive or corrosive conditions, stainless steel is safer.

2. Do Cast Iron Castings rust easily?

They can rust, yes. But coatings and proper finishing significantly reduce this.

3. Can I get custom shapes?

Absolutely. Our pattern shop builds moulds exactly as your design requires.

4. How long does cast iron last?

Years — sometimes decades — when used in the right environment.

5. How do I know which material to pick?

Tell us about your load, environment, and function. We’ll help you choose.

6. Do you provide machining?

Yes. You can request raw castings or fully machined, ready-to-install components.