Ductile Iron Castings in India

You often reach this point after working with ductile iron castings in India that fail to meet expectations. Your parts experience problems sooner than planned. Your machines slow down or shut down unexpectedly. And all the while, your operating costs silently increase.

We have worked with teams facing exactly these kinds of challenges. We know how faulty ductile iron castings impact not only your equipment but also your deadlines and commitments. That’s why we focus on supplying ductile iron castings in India that consistently perform well.

You will find all the answers to your questions in this blog if you are an engineer, buyer, or decision-maker, especially those who want reliable results right from the first delivery.

Why Ductile Iron Is Trusted When Failure Is Not an Option

Ductile iron earns its place in critical applications because it exhibits different behaviour under stress. It bends before breaking. It absorbs shock instead of transferring damage.

Unlike grey iron, ductile iron contains nodular graphite, which allows it to handle dynamic loads without sudden failure. That single property changes everything for you when parts face vibration, pressure, or unpredictable working conditions.

For your project, this means:

- Fewer breakdowns

- Longer service life

- Better safety margins

- Lower long-term maintenance costs

And in real-world operations, those benefits matter far more than textbook definitions.

India’s Foundry Ecosystem: Experience You Can Rely On

India has a casting legacy that did not appear overnight. It grew through decades of industrial demand, hands-on learning, and steady refinement.

Foundry clusters in and around Howrah, Durgapur, and nearby industrial belts supply ductile iron components to infrastructure projects, OEMs, export houses, and government utilities across India.

When you source ductile iron castings in India from a company like ours, you receive the following advantages:

- We have skilled metallurgists with many years of experience who possess a deep understanding of material behaviour.

- Our expert pattern makers rely on experience, not guesswork.

- A foundry capable of handling high-volume production while maintaining the quality of your parts.

It is this depth of expertise that leads many discerning buyers to choose this region for manufacturing their components, even when cheaper alternatives are available elsewhere.

What You Should Expect From a Reliable Ductile Iron Casting Company

Not every supplier deserves your trust. And you already know that a polished brochure means nothing if the casting fails on site.

A dependable ductile iron casting company should be able to:

- Discuss your application, not just your drawing

- Suggest grade improvements when needed

- Maintain uniform metallurgy across batches

- Deliver castings that machine cleanly without hidden defects

Good suppliers ask questions. They don’t rush you. They understand that your part must work long after it leaves the foundry gate.

Where Shree Krishna Industries Fits Into This Landscape

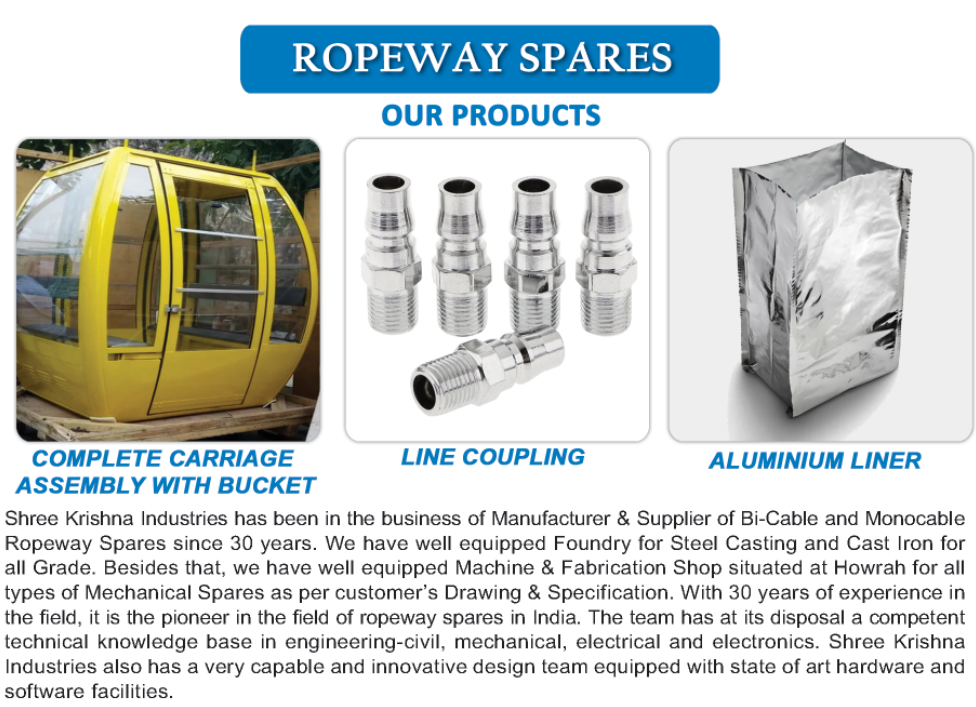

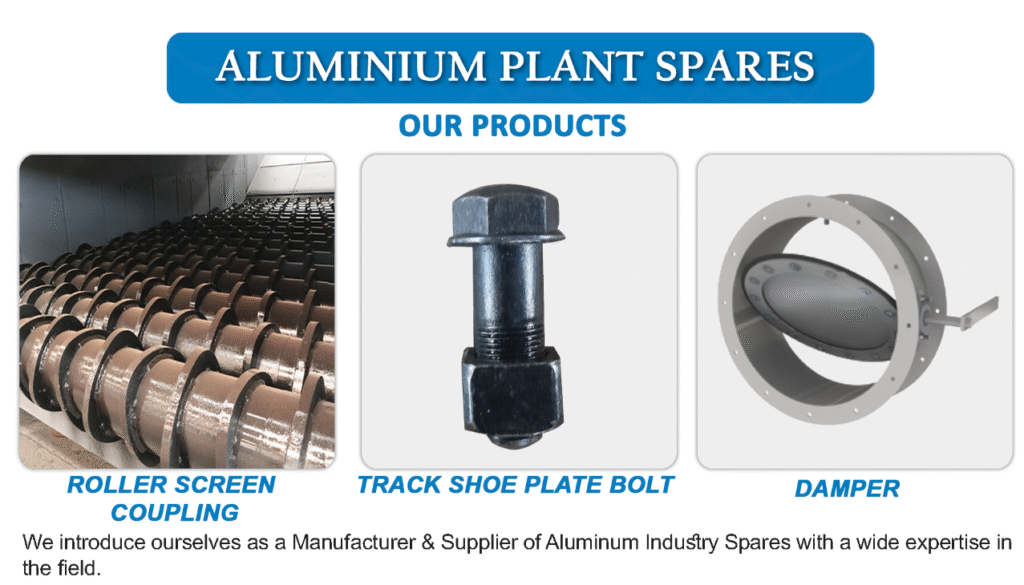

Within this competitive environment, Shree Krishna Industries has positioned itself as a manufacturer that values consistency over shortcuts. The focus here is not on chasing volume alone. It is on producing ductile iron castings that meet functional expectations in actual operating conditions, whether the component ends up in a pipeline system, industrial machinery, or structural assembly.

Customers often return not because of marketing claims, but because repeat performance builds quiet trust over time.

Applications That Demand Ductile Iron: And Why You Use It

You may already be using ductile iron without thinking twice about it. That’s usually a good sign.

Common applications include:

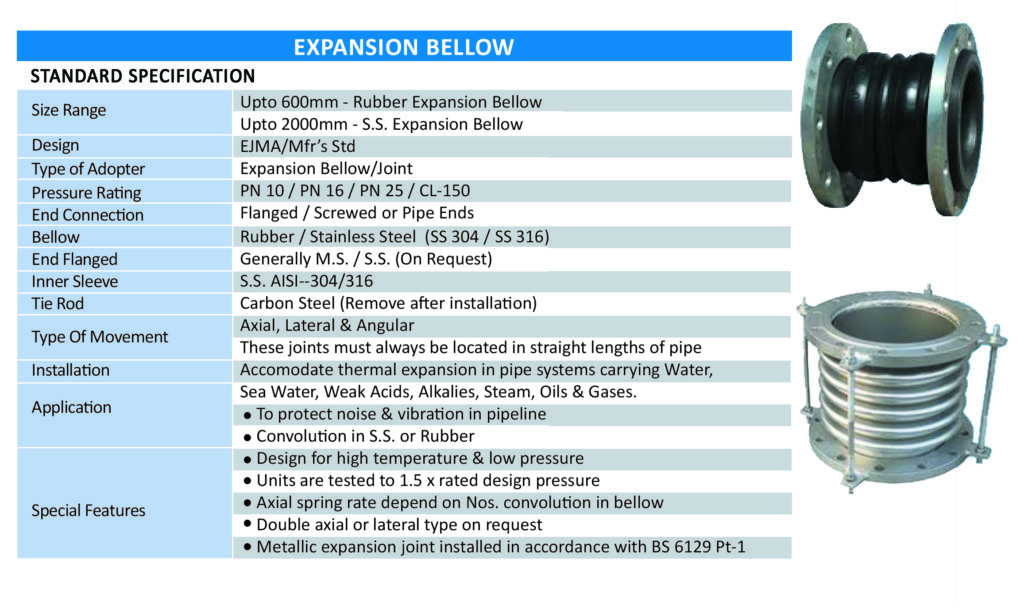

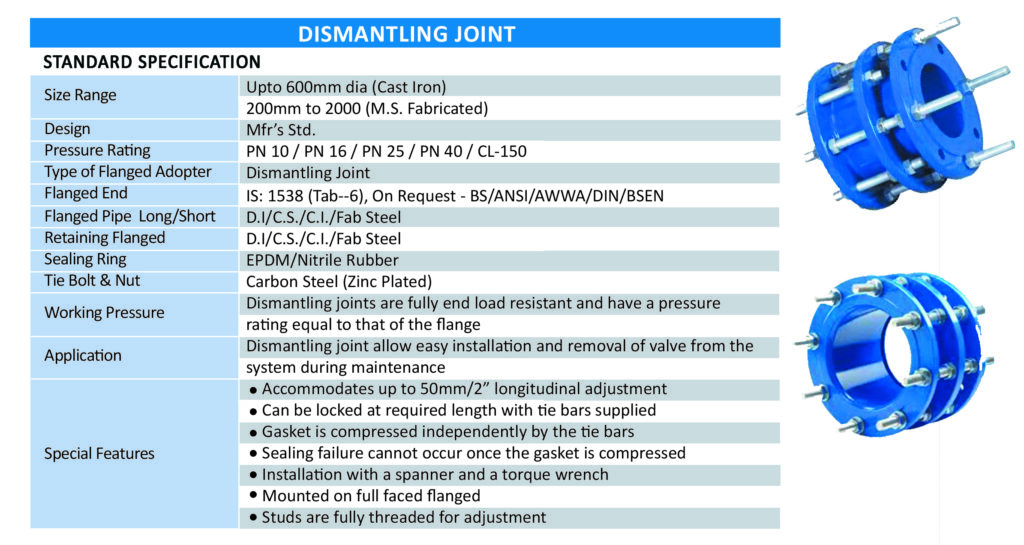

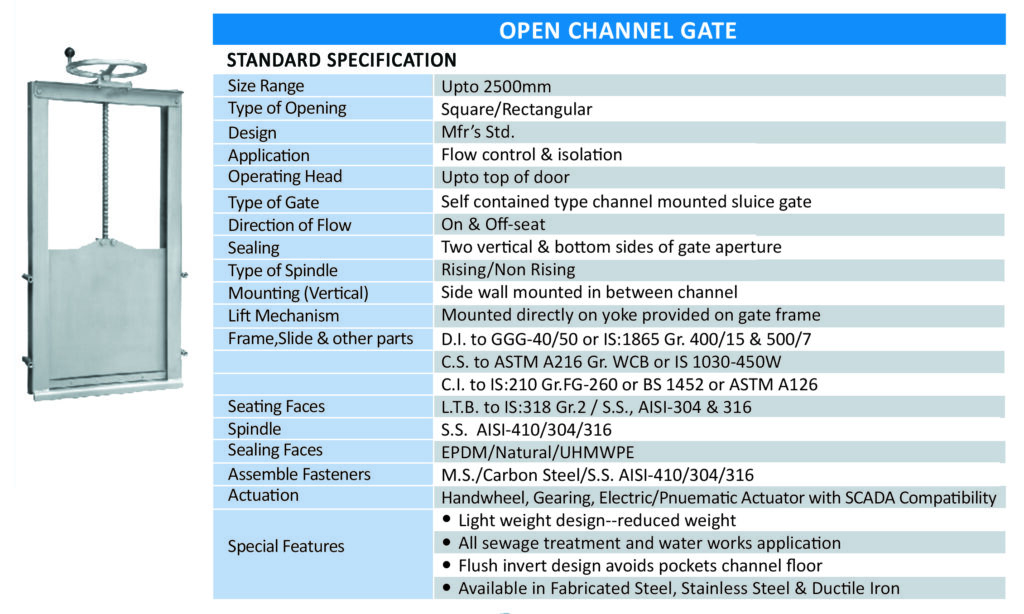

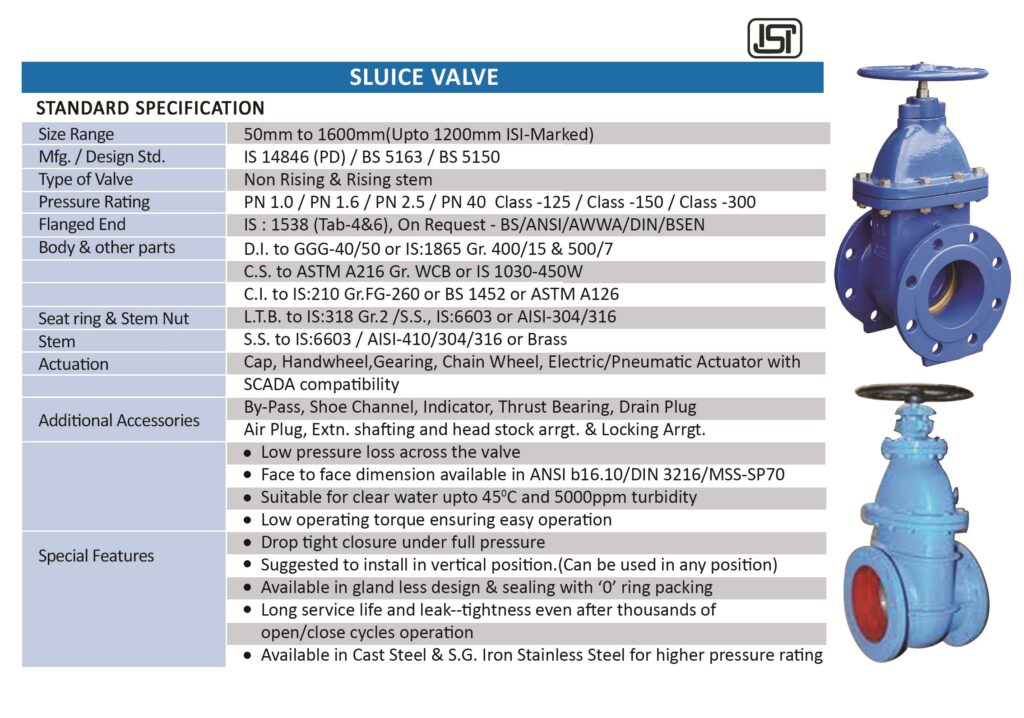

- Municipal water and drainage pipelines

- Automotive suspension and axle components

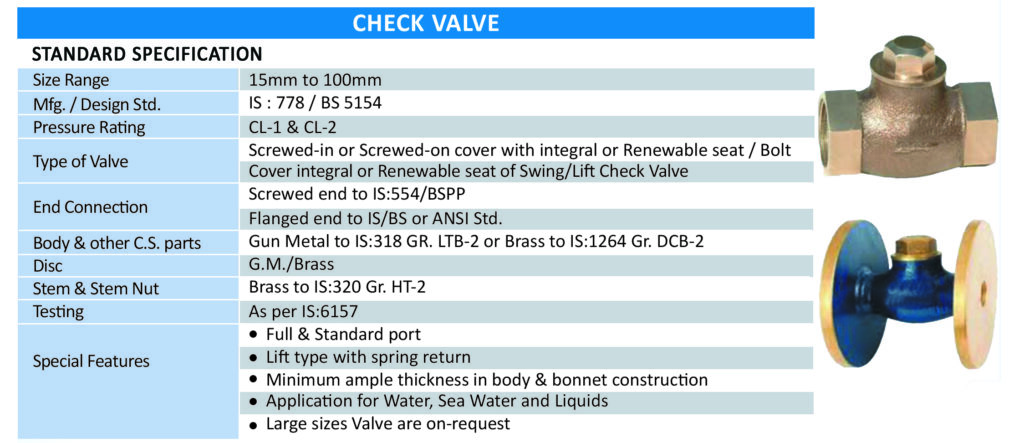

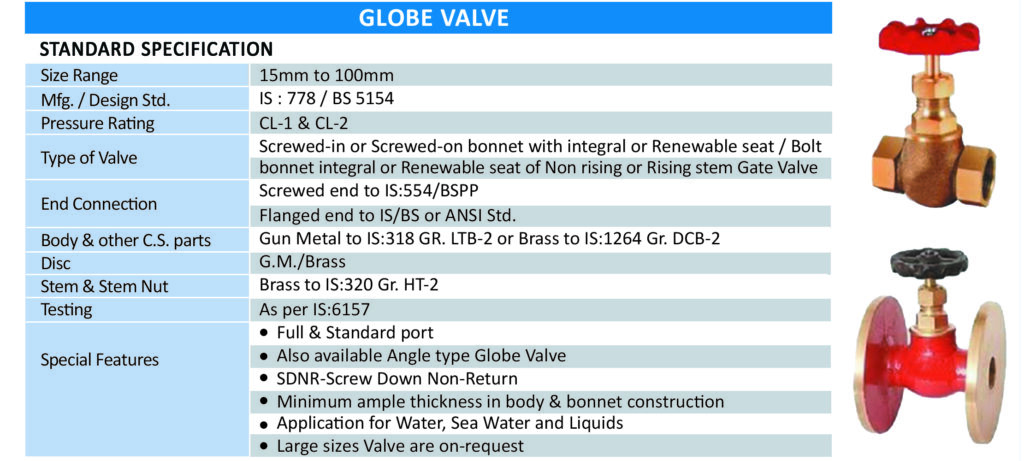

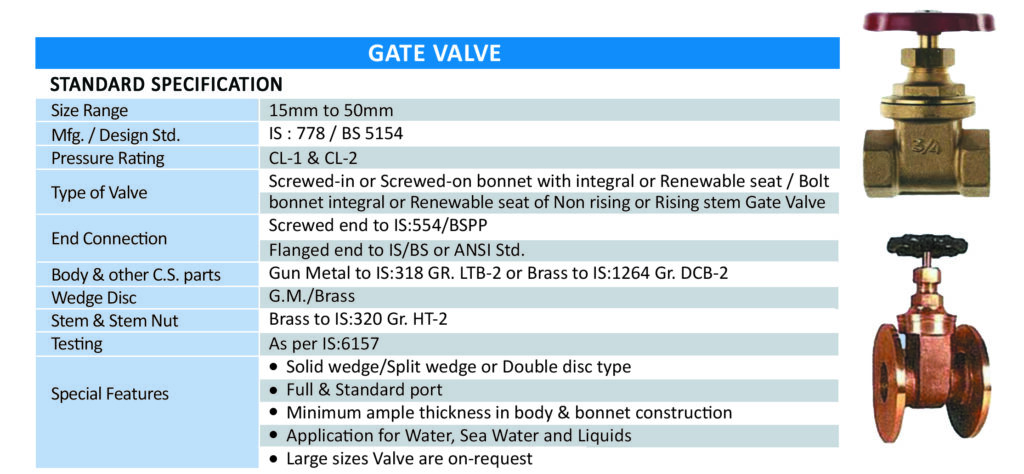

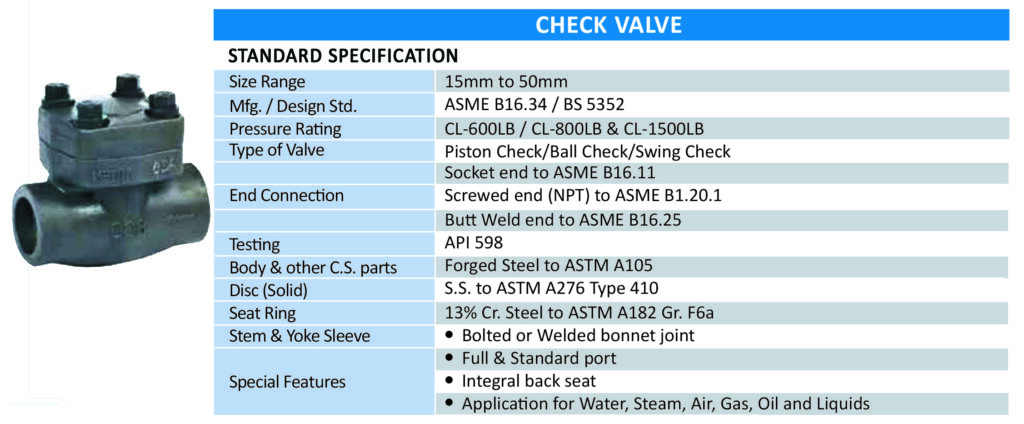

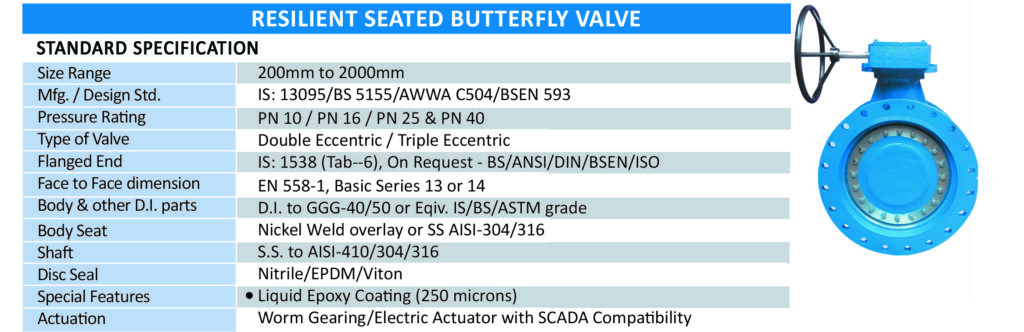

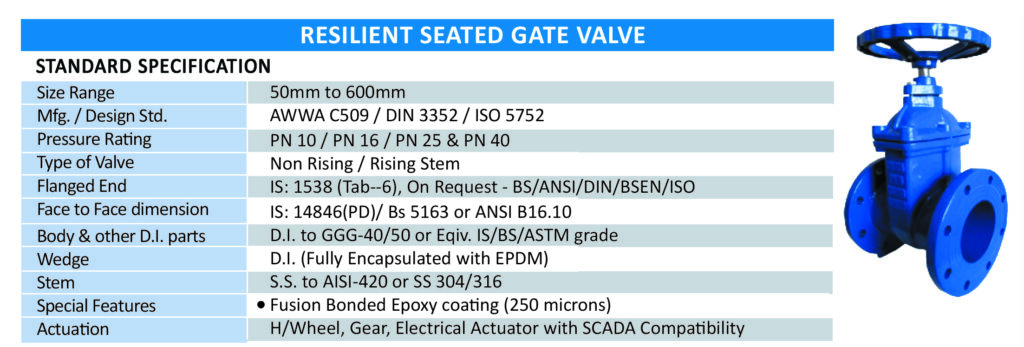

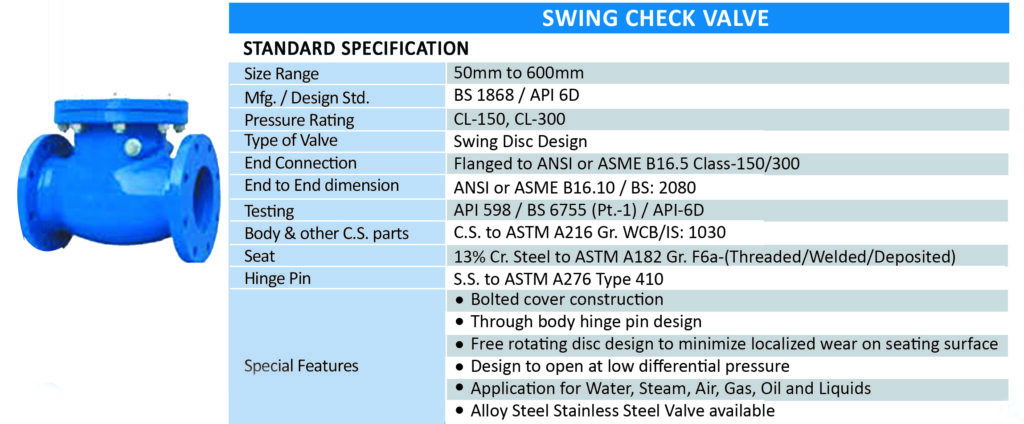

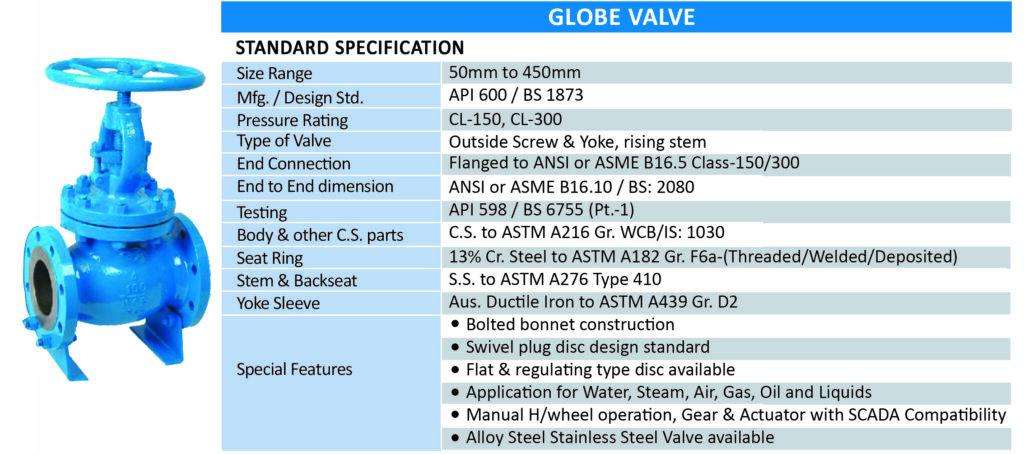

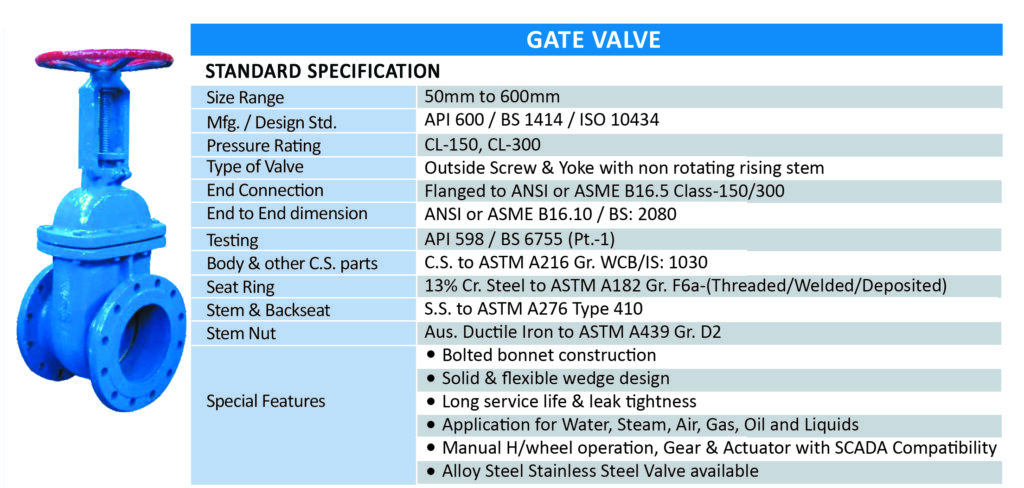

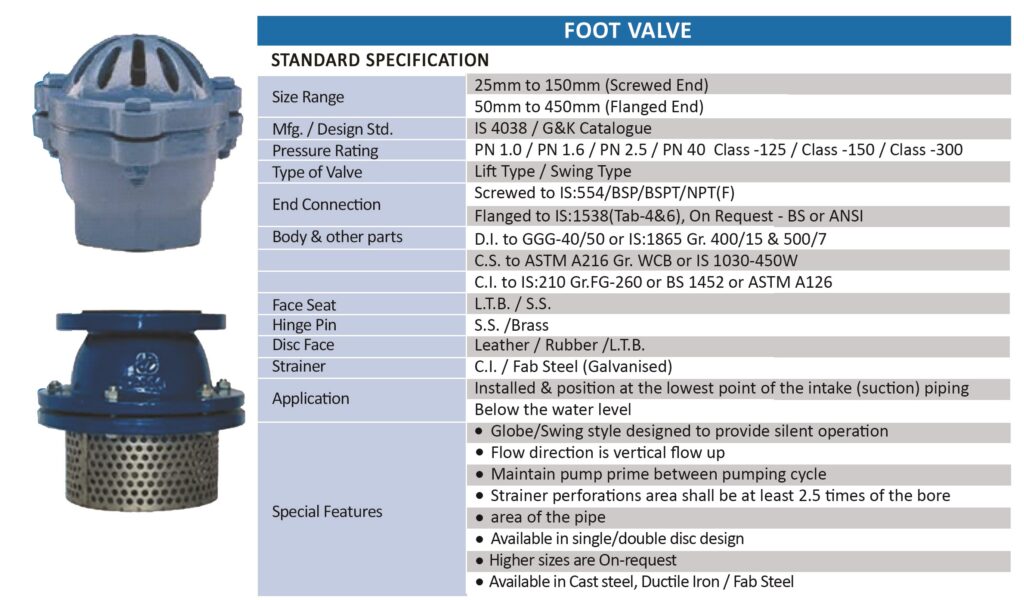

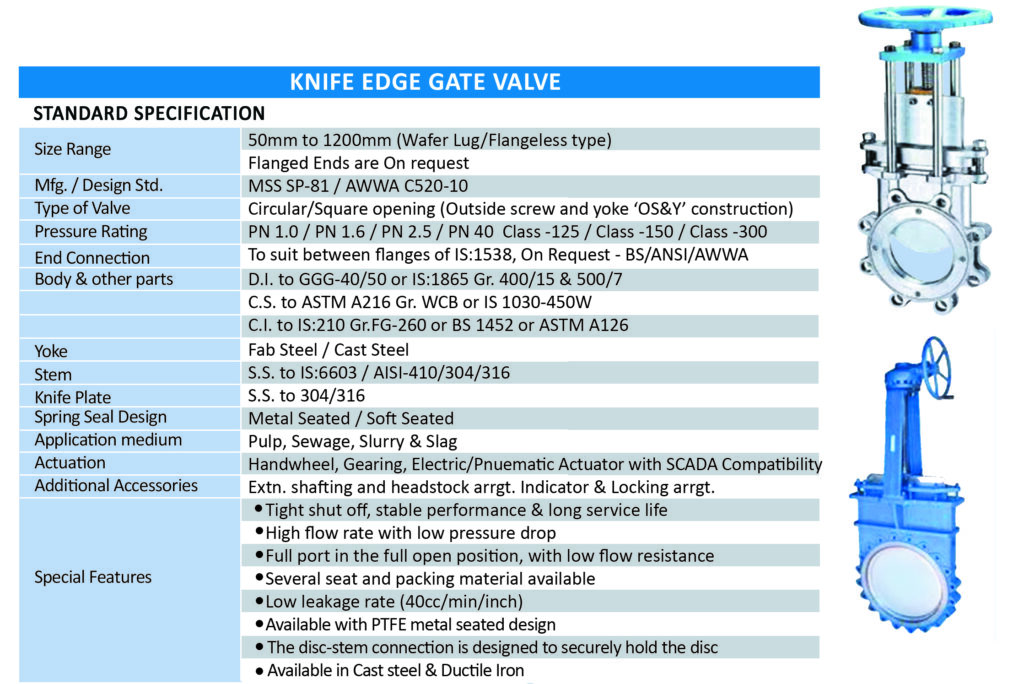

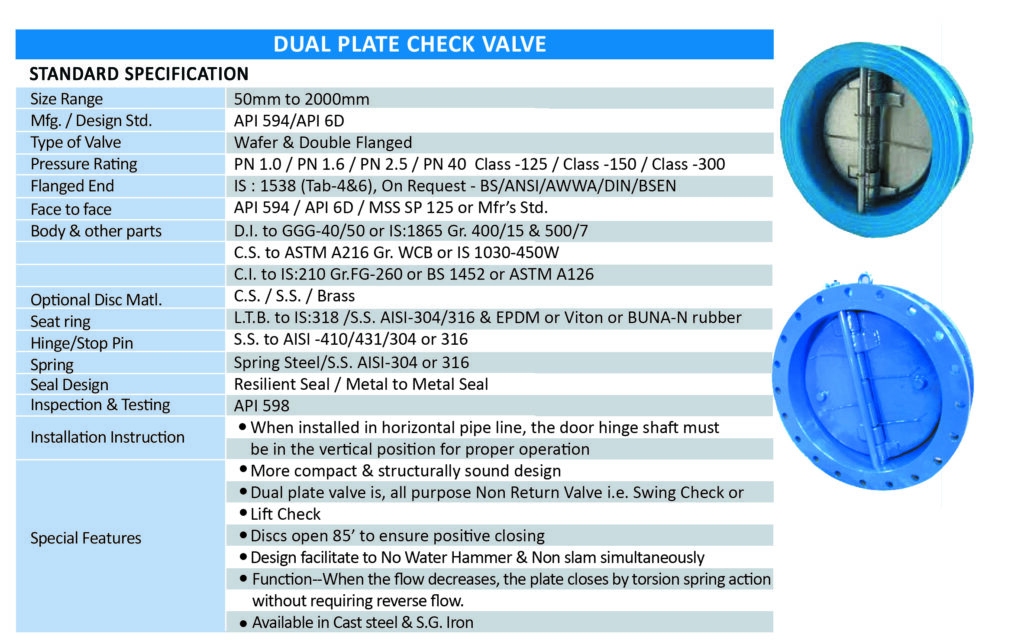

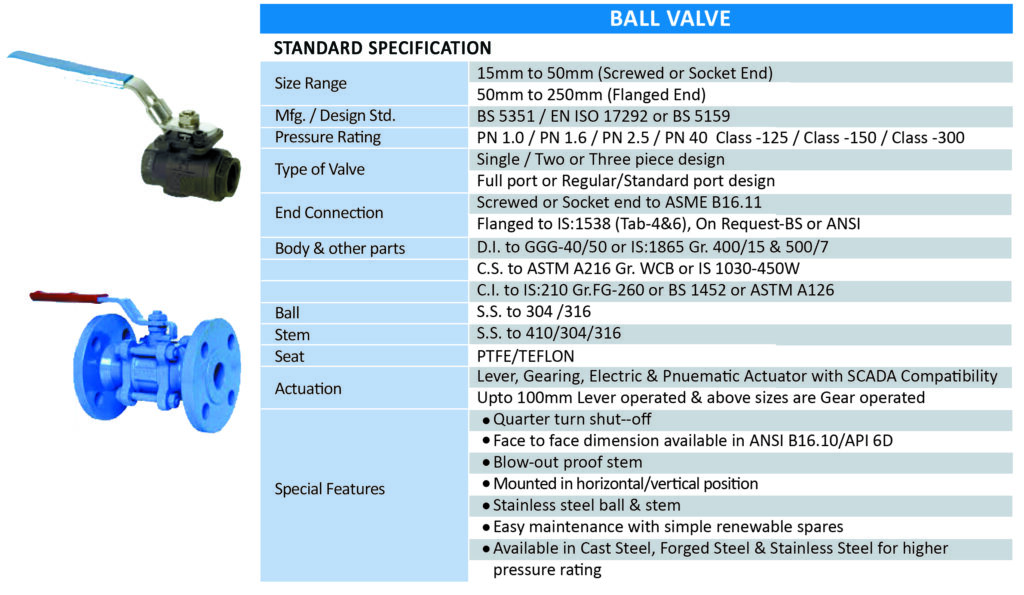

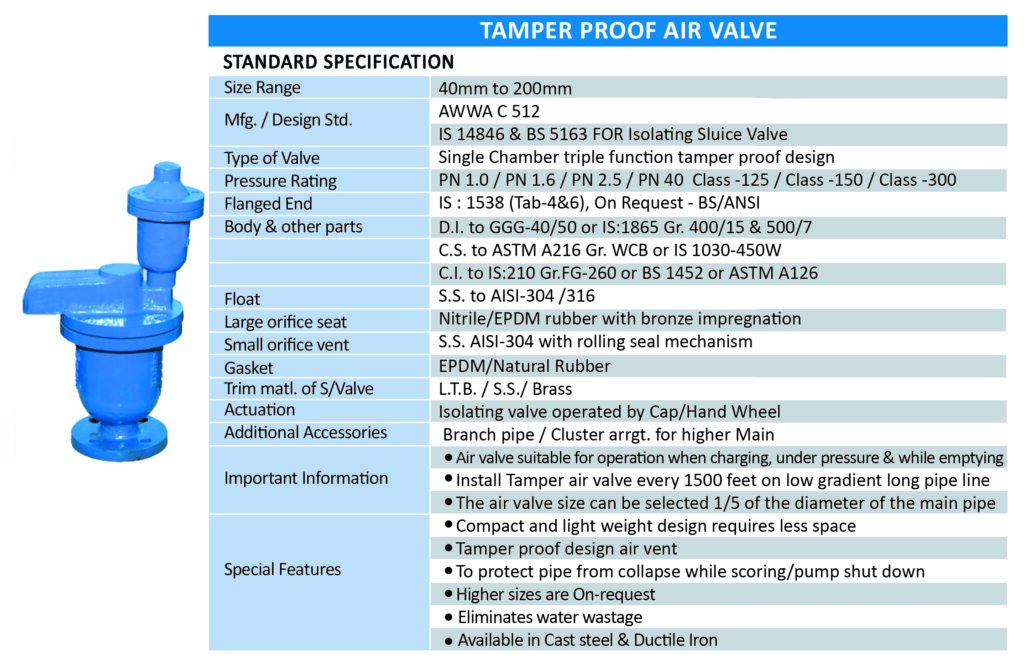

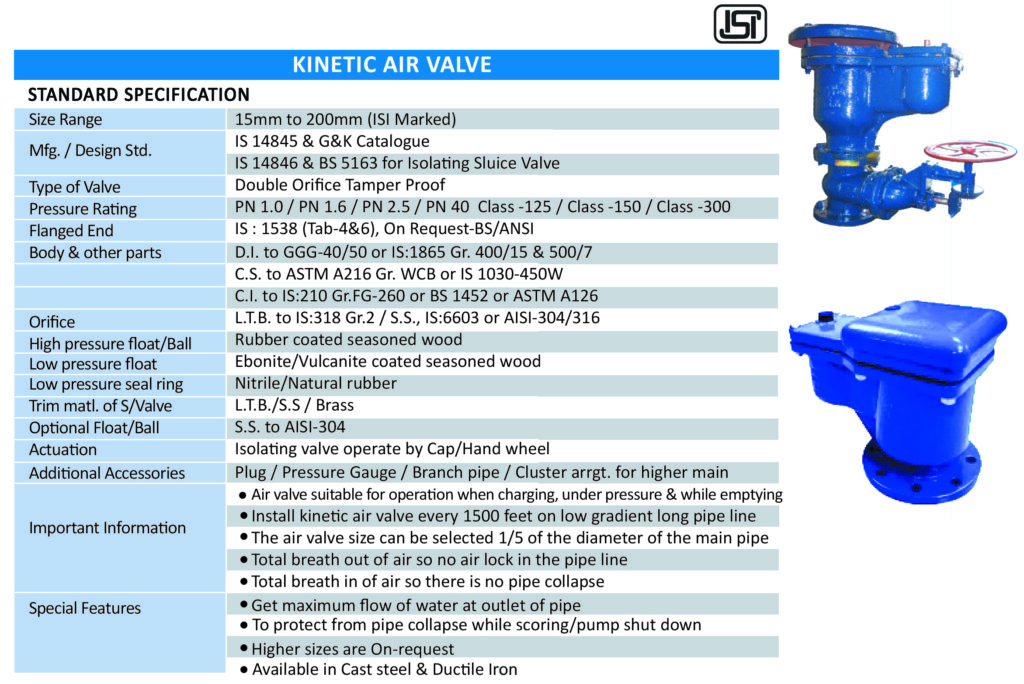

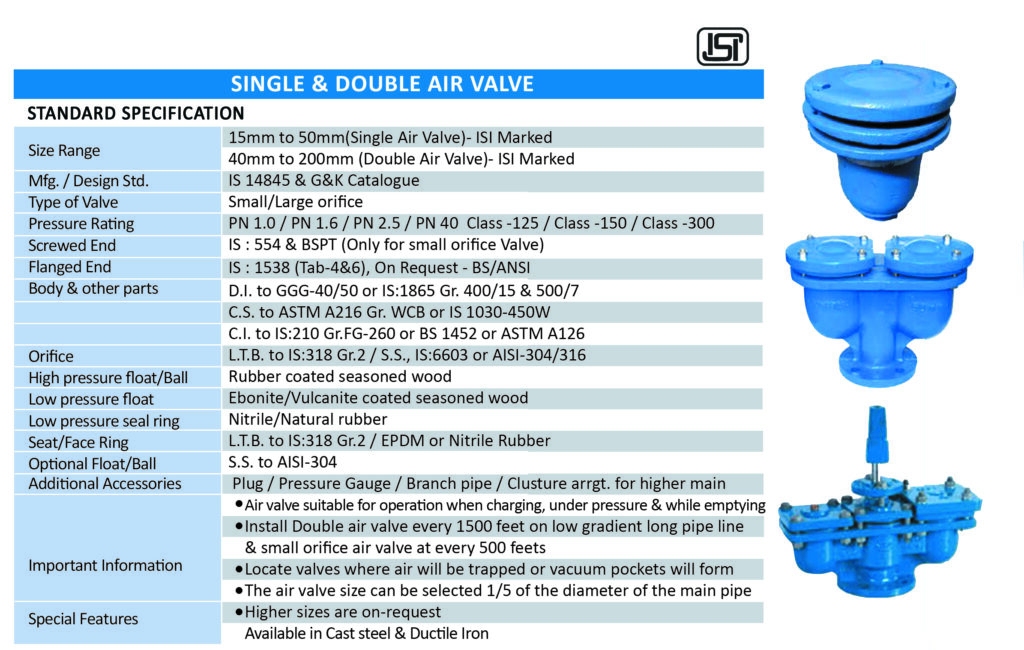

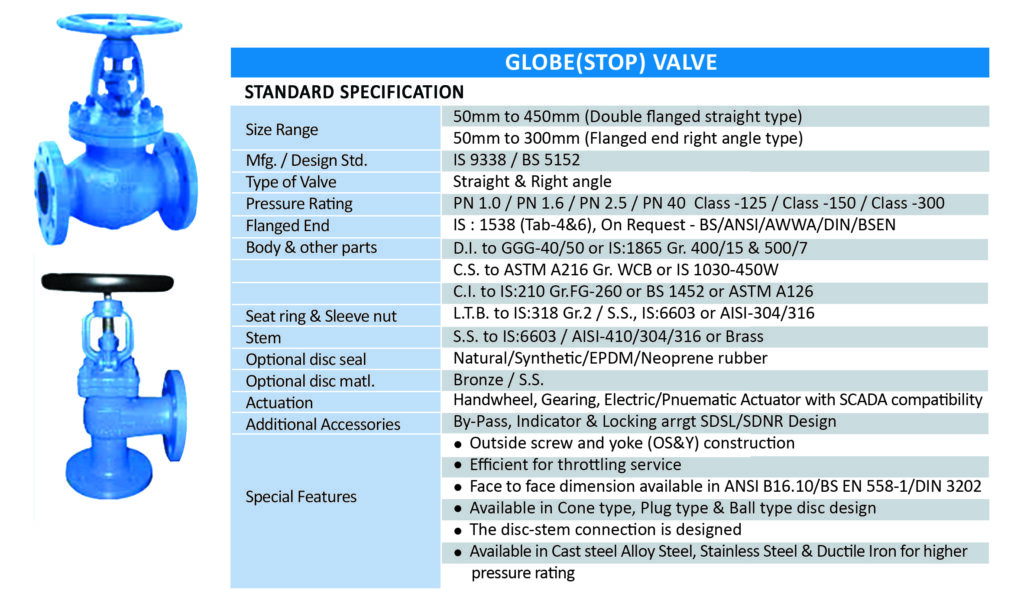

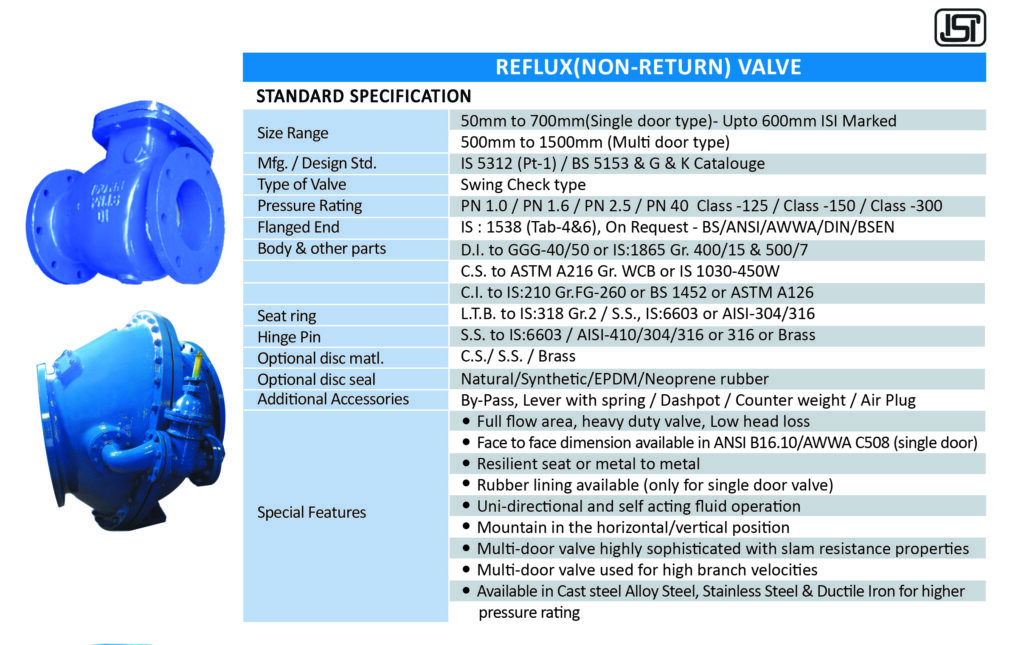

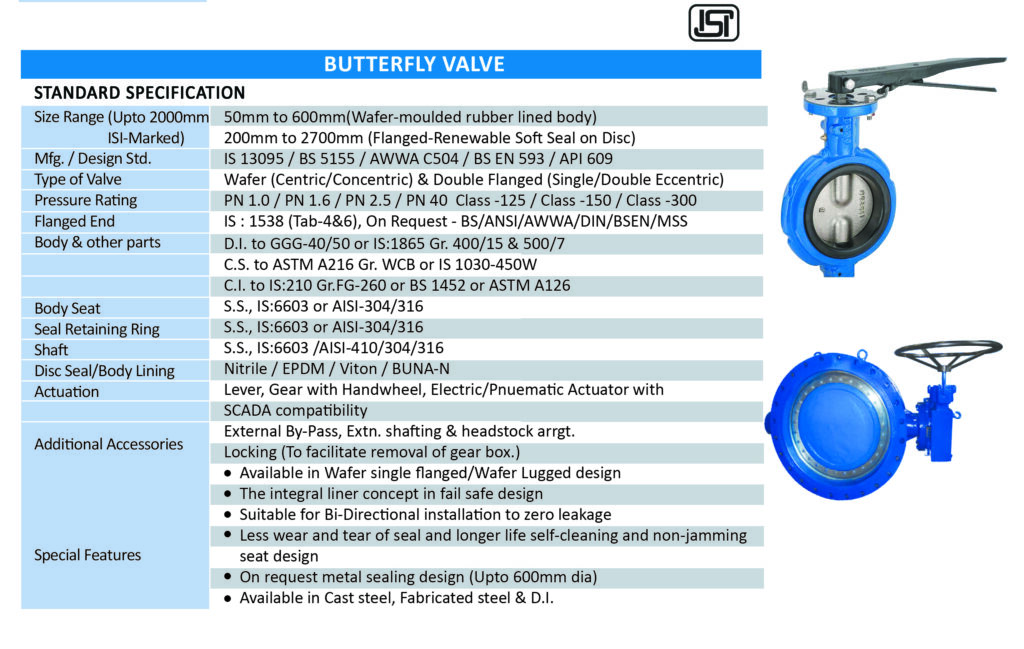

- Industrial valves and pump housings

- Heavy machinery brackets and frames

- Agricultural and earthmoving equipment

In each case, the material is chosen because it handles load variation, shock, and wear better than many alternatives at a comparable cost.

When failure leads to downtime or safety risk, ductile iron becomes the logical choice.

Choosing the Right Ductile Iron Casting Suppliers

Finding reliable ductile iron casting suppliers is less about searching online and more about knowing what to ask.

Before placing an order, you should feel comfortable asking:

- How do you control nodularity and chemistry?

- What testing is done before dispatch?

- Can you support repeat orders with the same quality?

- How do you handle rejection or rework?

Suppliers who answer clearly are usually the ones worth working with. Those who avoid specifics often reveal more than they intend.

Quality Is Not Just a Certificate

ISO certificates help. Testing equipment matters. But quality, in casting, still depends heavily on discipline inside the foundry. Molten metal does not forgive carelessness. One rushed pour can undo weeks of planning.

This is why companies like Shree Krishna Industries emphasise controlled processes, from raw material selection to final inspection, rather than relying only on post-production checks. Good castings are made right the first time. Everything else is damage control.

Cost vs Value: A Conversation Worth Having

It is tempting to chase the lowest quote. We understand that pressure. But experienced buyers know that cheaper castings often cost more later, through machining losses, premature failures, or delayed installations.

Value comes from:

- Dimensional accuracy

- Clean internal structure

- Predictable performance in service

When your supplier understands this balance, you stop firefighting and start planning ahead.

Why Buyers Keep Coming Back

Long-term relationships in the casting industry are rarely built on contracts alone.

They are built on consistency.

When your supplier delivers:

- On the promised timeline

- With predictable quality

- Without excuses

- You stop worrying about that part of your supply chain.

That reliability is what keeps Shree Krishna Industries relevant in a market where buyers have many options but little patience for mistakes.

Built for Real Work, Not Just Specifications

If you are evaluating ductile iron castings in India, it’s crucial to look beyond just the price list. First and foremost, consider where the component you are having manufactured will be used and what the consequences of its failure would be for your business. Think about whether your supplier truly understands your needs.

When these questions guide your decision-making, finding the right casting partner becomes much easier. And when reliability is more important than promises, experience silently proves its worth.

FAQs

What makes ductile iron different from grey iron?

Ductile iron bends under stress, while grey iron tends to crack suddenly.

Are ductile iron castings suitable for outdoor use?

Yes, especially when proper coatings or treatments are applied.

Can India suppliers handle bulk orders?

Many foundries here are equipped for large and repeat production runs.

How can I ensure the quality of the castings is correct before delivery? Is this possible?

Yes. You can request test reports from us or approve a sample and verify the foundry’s inspection procedures before anything is shipped. This will make it easier for you to address any concerns.

Can your company manufacture customised castings for the specific uses of my business?

Absolutely, we can do customised castings for you. Our expert team can create an ideal casting for your business by adjusting the dimensions and material grade to suit your part’s application