If you’ve ever watched a machine stop mid-operation because a part gave up, you already understand why material choice matters. On paper, many metals look strong. In real life, under load and pressure, only a few actually last. That’s usually when ductile iron casting enters the conversation.

We don’t talk about ductile iron as a trend or a specification. We talk about it because we see how it performs when conditions are not ideal. And most heavy-duty applications are never ideal.

What Really Sets Ductile Iron Apart

Ductile iron doesn’t behave like ordinary cast iron. Instead of snapping when it reaches its limit, it stretches slightly. That small amount of flexibility changes everything when your component faces vibration, shock, or uneven loads.

If your equipment runs long hours or works in unpredictable environments, that flexibility becomes a form of protection. As a ductile iron foundry, we’ve seen components survive situations where more brittle materials fail without warning.

In fact, such an event is not a matter of chance. It is crucial to have controlled production and precise knowledge of what the metal requires at each stage, because the outcome depends on it.

Power You Can Rely on With Confidence, Not Just in Measurements

We know that any heavy-duty task requires power. It requires power that maintains its effectiveness even under real working pressure, without failing midway. You need strength that holds up at three in the morning when the system is under stress.

Spheroidal graphite iron castings provide high tensile strength while staying stable during operation. They don’t deform easily, and they don’t give up suddenly either. That balance makes nodular iron casting suitable for parts that carry weight continuously.

When you’re responsible for keeping production running, that predictability matters more than impressive numbers.

Handling Impact Without Falling Apart

Machines don’t move gently. Loads shift. Motors jerk. Systems vibrate. Over time, those forces add up. Spheroidal graphite iron castings absorb impact instead of fighting it. Rather than developing cracks that slowly spread, the material takes the hit and keeps going. For your business, this means fewer unexpected disruptions and less stress regarding maintenance schedules.

Many clients come to ductile iron manufacturers after facing repeated failures with conventional materials. They’re usually looking for peace of mind as much as performance.

Fatigue Resistance That Pays Off Over Time

Some failures don’t happen suddenly. They build quietly, cycle after cycle, until something finally gives way. Ductile iron casting resists this kind of fatigue better than many alternatives. Its structure slows down crack formation even when loads repeat daily. If your components are able to remain in continuous motion, this resistance can significantly extend their lifespan. This longer lifespan directly and effectively impacts your operating costs, although the effect may not be immediately visible to you.

Machining Without Unnecessary Headaches

Strong materials are often difficult to machine. That’s where ductile iron surprises many people. Despite its durability, ductile iron remains machinable. This allows ductile iron manufacturers to deliver parts that meet precise tolerances without excessive tool wear or time loss. From your side, machining becomes smoother, assembly becomes easier, and production stays on schedule.

Why Consistency From a Ductile Iron Foundry Matters

One good casting doesn’t solve your problem if the next one behaves differently. Inconsistency can lead to major problems in heavy-duty applications.

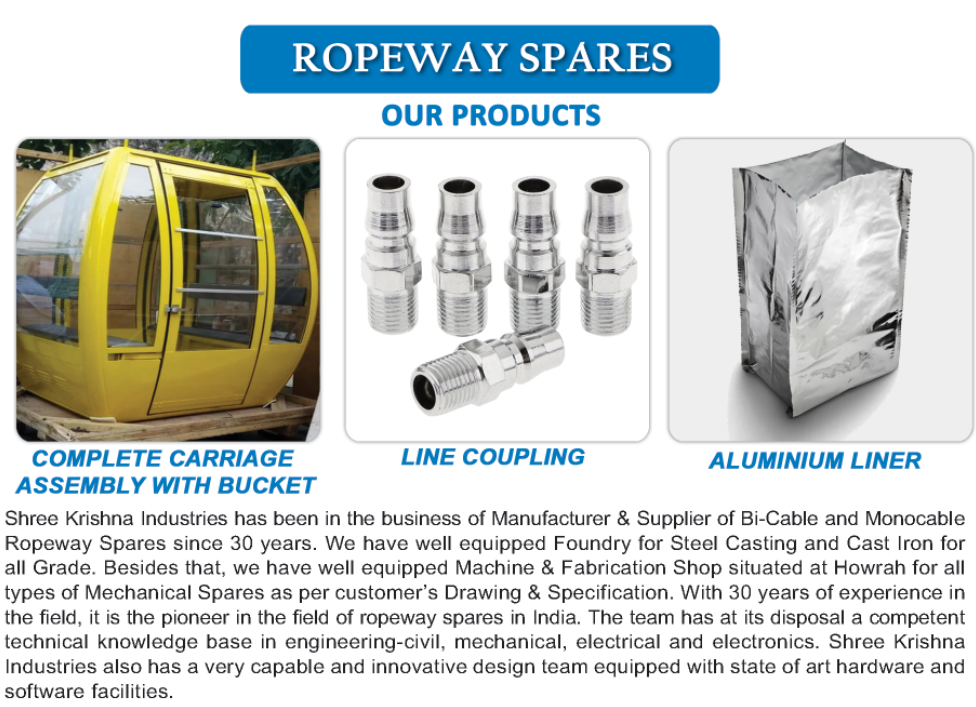

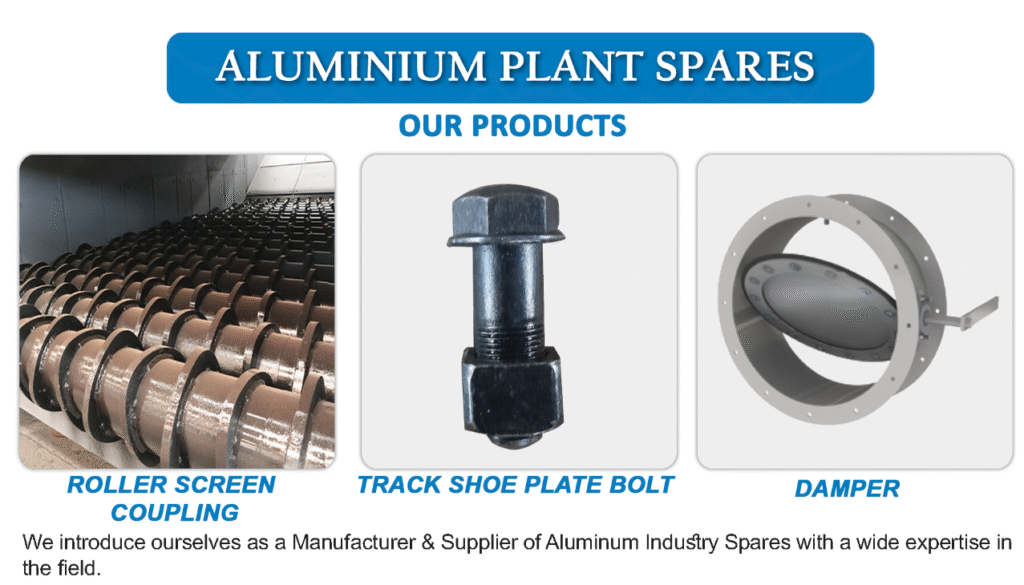

A trustworthy ductile iron factory prioritises consistent outcomes above isolated achievements. To ensure that every batch performs consistently, we at Shree Krishna Industries regulate the raw materials, melting conditions, and processing. You can plan without worrying about quality because of such consistency.

Looking at Ductile Iron Price the Right Way

It’s natural to compare ductile iron price with basic cast iron or steel alternatives. On the surface, ductile iron may appear costlier. However, the total cost usually works in your advantage when you consider the longer life, fewer failures, and less downtime. It’s not only metal you’re paying for. You’re making a stable investment. We assist you in selecting grades that are appropriate for your application to avoid overspending or performing poorly.

Choosing More Than Just Ductile Iron Manufacturers

Material alone doesn’t guarantee success. The people producing it matter just as much.

At Shree Krishna Industries, as a ductile iron factory, we take time to understand where your component will be used and what it must endure. That context shapes how we approach production.

When you work with us, you’re not just buying nodular iron castings. You’re working with a team that thinks about how your equipment will actually run.

Built for Heavy-Duty Work, Backed by Experience

Ductile iron casting continues to be trusted in heavy-duty applications because it handles real-world stress better than many alternatives. It bends instead of breaking. It absorbs impact. And it lasts longer.

If your operation demands strength with resilience, ductile iron is not just suitable. It’s practical.

FAQs

1. Why is ductile iron casting used in heavy-duty applications?

Because it combines strength with flexibility and impact resistance.

2. Is ductile iron better than regular cast iron?

For demanding conditions, yes. It handles stress more reliably.

3. How does the ductile iron price compare over time?

It often saves money through longer service life and fewer failures.

4. Do ductile iron manufacturers offer application-based grades?

Yes. Grades are selected based on how the part will work.

5. How do I choose the right ductile iron foundry?

Look for consistency, experience, and clear communication.