Cast Steel Castings in India

When people talk about cast steel castings in India, like everyone else, you too often focus more on grades, strength specifications, or technical terminology, right? Of course, these are truly important aspects. But if you run a plant or manage a project, your first concern won’t be so complicated. Because we know that you want your part to function properly, without causing any problems for your business in the meantime. You want it to fit correctly, and after installation, you want to be able to continue your work without any unexpected issues.

In fact, we have been working on castings with this mindset for years, with success and trust. We think about your part in every possible way. Specifically, we want to know where your part will be used, how long it needs to last, and what kind of stress it might face after leaving our foundry. This realistic thinking makes all our work simple and successful.

Why Cast Steel Still Has a Place in Today’s Industry

Cast steel is nothing new; it has been used for various applications for decades. Yet, many industries still rely on it for a specific reason: it holds up exceptionally well under adverse conditions. Sudden loads, vibrations, heat, or pressure do not affect it as quickly as they would lighter materials.

So, when you choose components made of cast steel, you are choosing a material that doesn’t give up easily. In fact, it bends before it breaks, allowing you to easily recognise when replacement is needed. It can absorb impacts very well without cracking unexpectedly. For machinery, infrastructure, or heavy equipment, this characteristic is far more important for your smooth business operations than polished aesthetics. We see cast steel as a working material, not a showroom material.

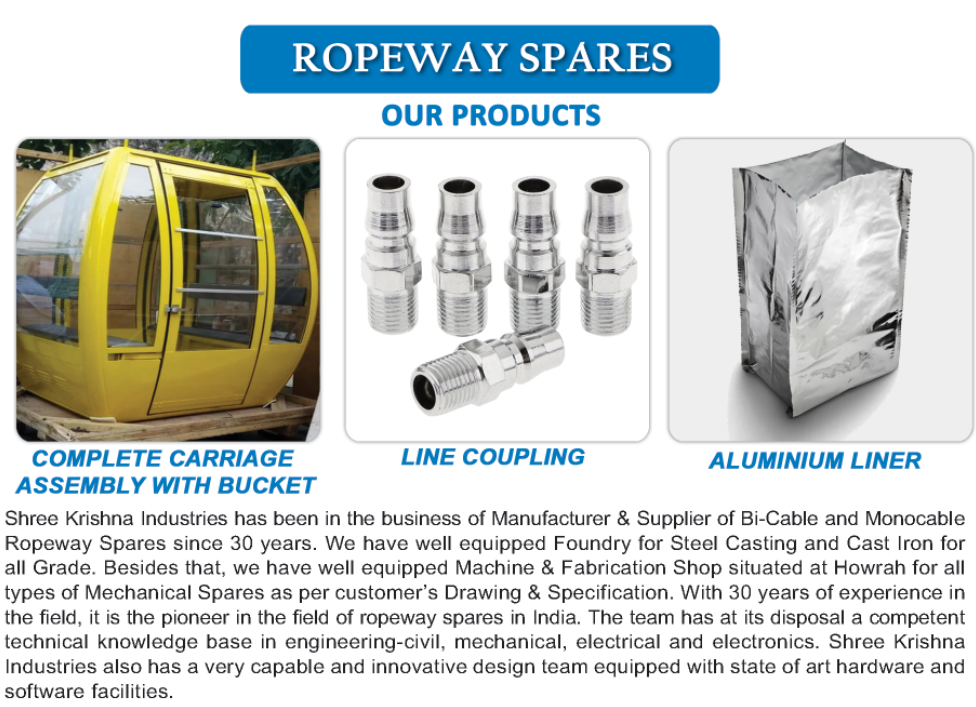

Our Approach at Shree Krishna Industries Is Straightforward

We do not believe casting is just pouring molten metal into a mould and waiting. Every order behaves differently once it reaches the field. Some face continuous load. Some face irregular stress. Others operate in dusty or high-temperature environments.

At Shree Krishna Industries, we take time to understand what you are dealing with. Sometimes clients know exactly what they want. Sometimes they only know the problem they are facing. Both situations are fine. We adjust our approach accordingly.

That is how we have been delivering cast steel castings in India that are actually usable, not just acceptable on paper.

Metal Casting That Respects the Basics

A lot of casting problems come from ignoring the basics. Poor melting control. Rushed moulding. Inconsistent cooling. These things may not show immediately, but they appear later as failures.

Our metal casting process is steady and controlled. We focus on temperature consistency, material quality, and proper solidification. It is not flashy work. It is patient work. And that patience shows in the final product. We would rather take a little longer and deliver something reliable than rush and create problems for you later.

Cast Steel Castings Made to Fit Real Equipment

No two machines behave the same way. Even similar machines, working in different locations, age differently. That is something you only learn by experience. Our cast steel components are developed keeping real operating conditions in mind. We look at alignment issues, mounting stress, and wear points. We try to ensure that once your team installs the component, it stays there doing its job quietly. If a casting works without drawing attention to itself, we consider that a success.

Stainless Steel Casting for When Conditions Are Unforgiving

There are situations where cast steel is not enough. Moisture, chemicals, or constant exposure to corrosive elements demand a different solution. This is where stainless steel casting becomes relevant. It does not rust easily. It maintains surface integrity. And it lasts longer in harsh environments.

We do not push stainless steel where it is not needed. But when your application demands it, we make sure you get a casting that performs without constant maintenance headaches.

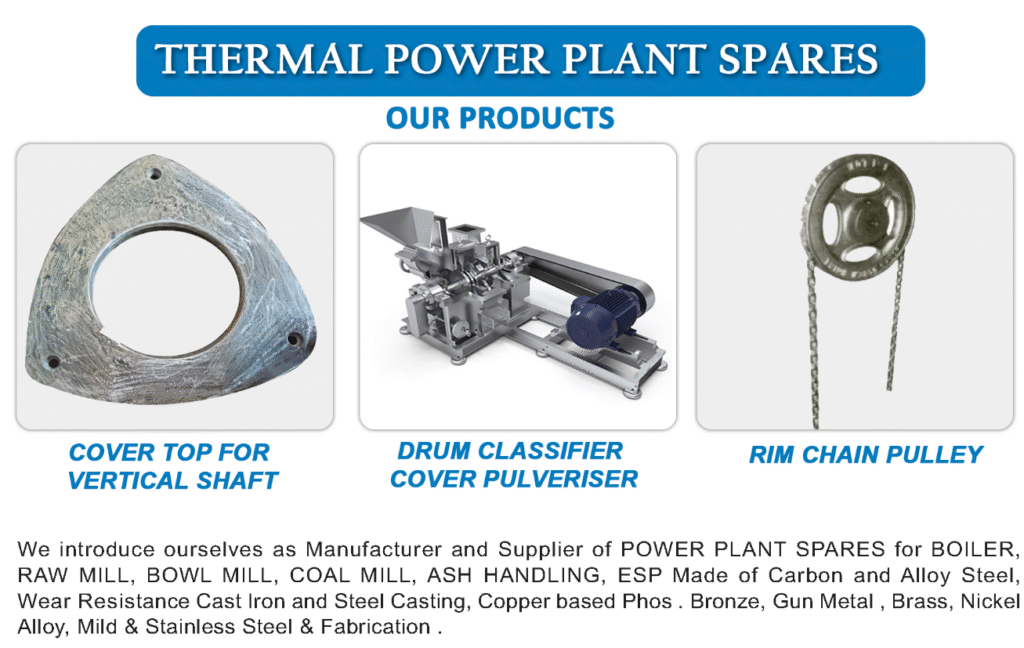

Industries We Work With, and What We See on the Ground

Over time, we have supplied castings to different sectors. Each one has taught us something. Infrastructure projects often need sheer strength and consistency. Heavy engineering clients focus on precision and load behaviour. Power sector components face continuous stress and heat. These are not textbook conditions. These are working conditions. Our experience with cast steel castings in India comes from dealing with these realities, not just specifications.

Quality Control Is Not a Separate Department for Us

In many places, quality is treated as a final step. For us, it runs alongside production. We check castings as they move through stages. And we look for visible flaws. We verify dimensions. We do not assume things are correct just because the process was followed.

This habit reduces rework. It reduces rejection. More importantly, it reduces the chances of you facing problems after delivery.

Custom Requirements Are Not an Inconvenience

Not every requirement fits a standard mould. We understand that. Some clients come with detailed drawings. Others come with older parts that have failed and ask us to improve them. We are comfortable with both. Custom cast steel components often solve problems that standard components cannot.

We discuss, adjust, and sometimes suggest changes based on what we have seen work in similar situations. That exchange usually leads to better outcomes for both sides.

Why Clients Continue Working With Shree Krishna Industries

Clients do not stay because of brochures. They stay because things work. They know they can talk to us openly. And they know we will not overpromise. They know if something needs clarification, we will say it. That is how trust develops. Slowly, but solidly.

Cast Steel Castings in India With Local Understanding

FAQs

Every factory in India operates in tough conditions, including heat, dust, vibration, humidity and heavy loads, among others. That is why industries have been relying on our castings for years for the following tasks:

- Machine housings

- Counterweights

- Gearbox parts

- Pump bodies

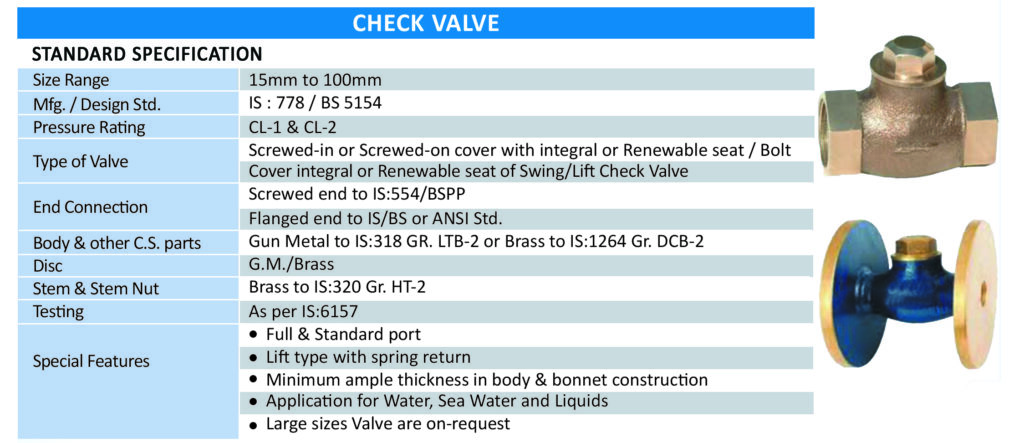

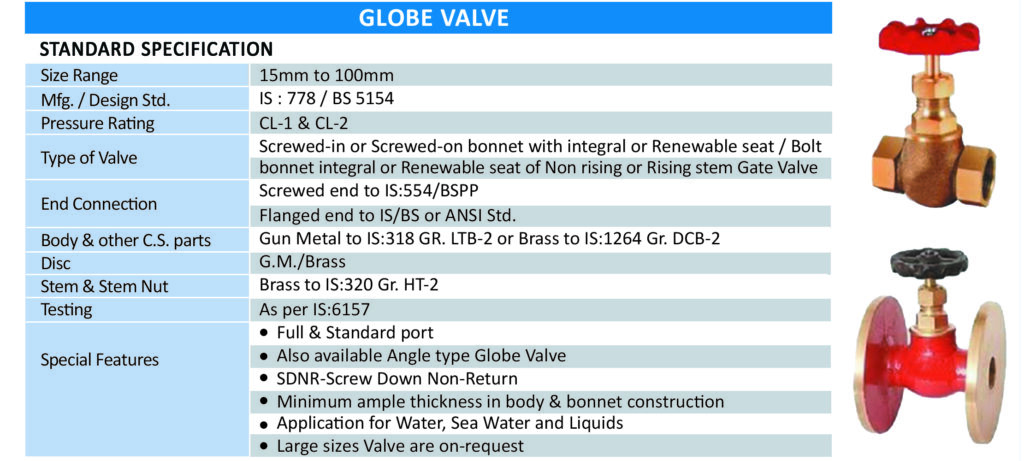

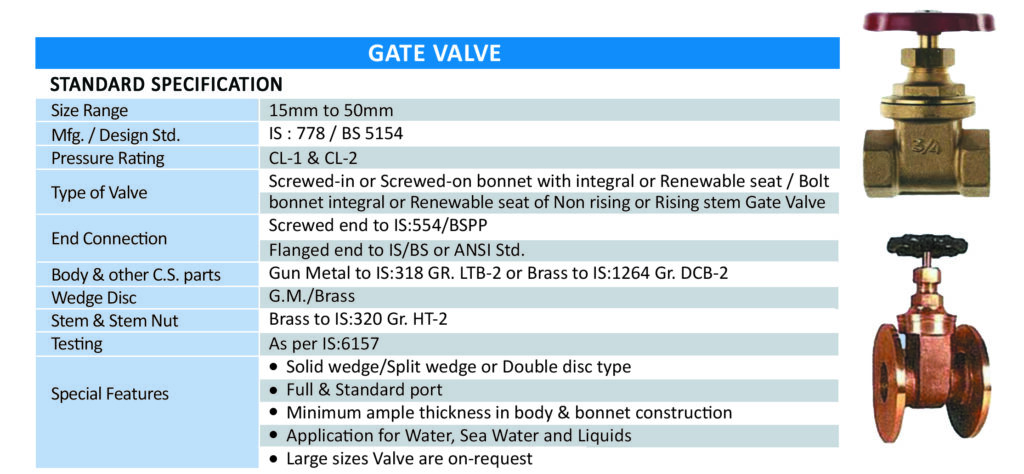

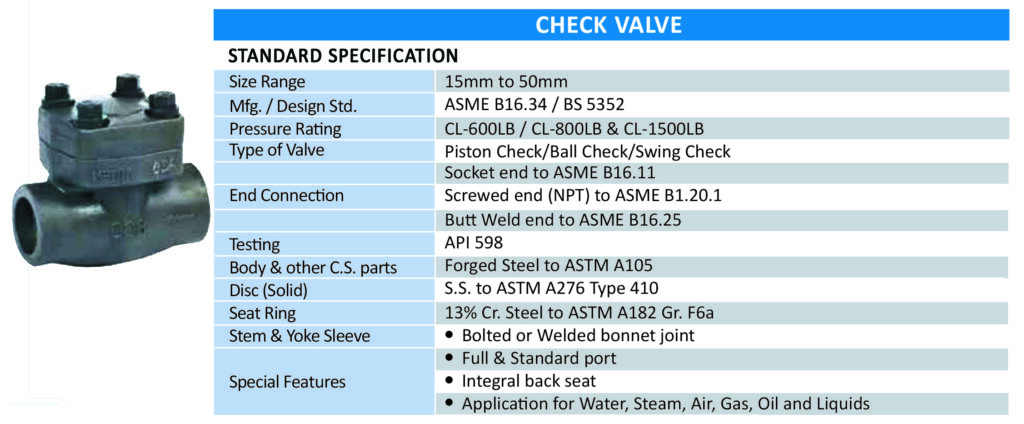

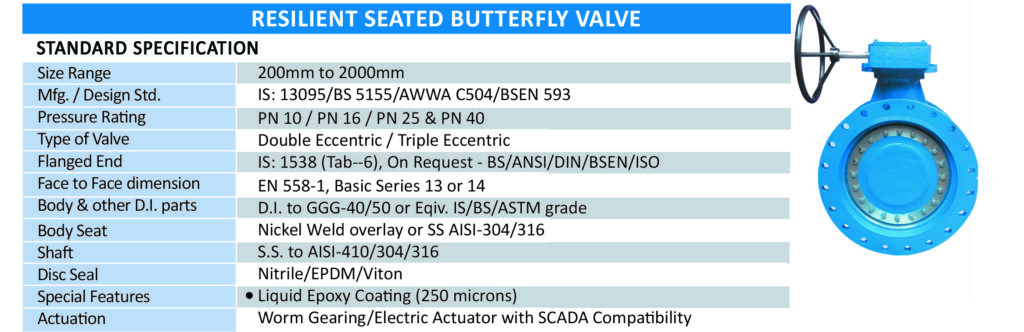

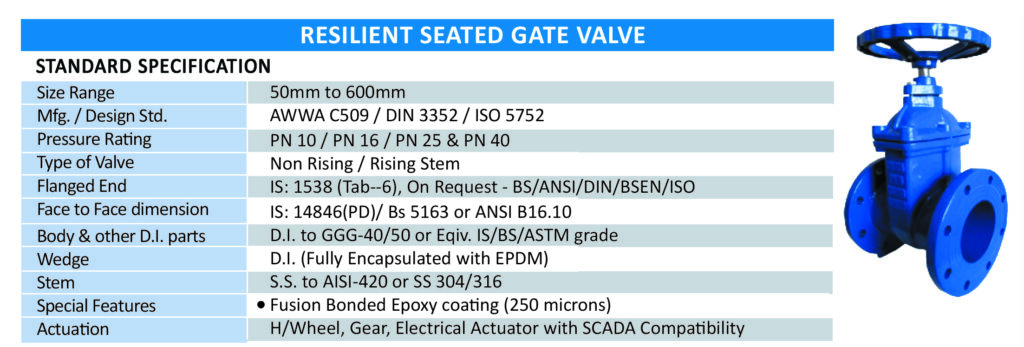

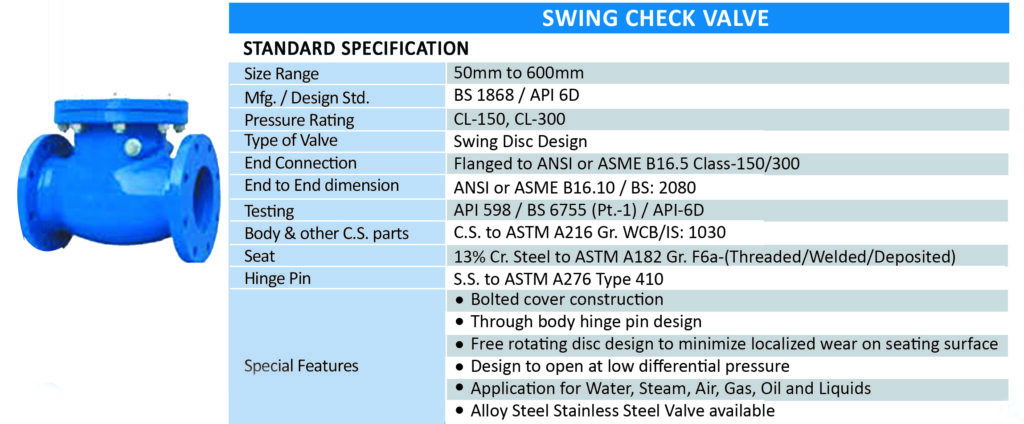

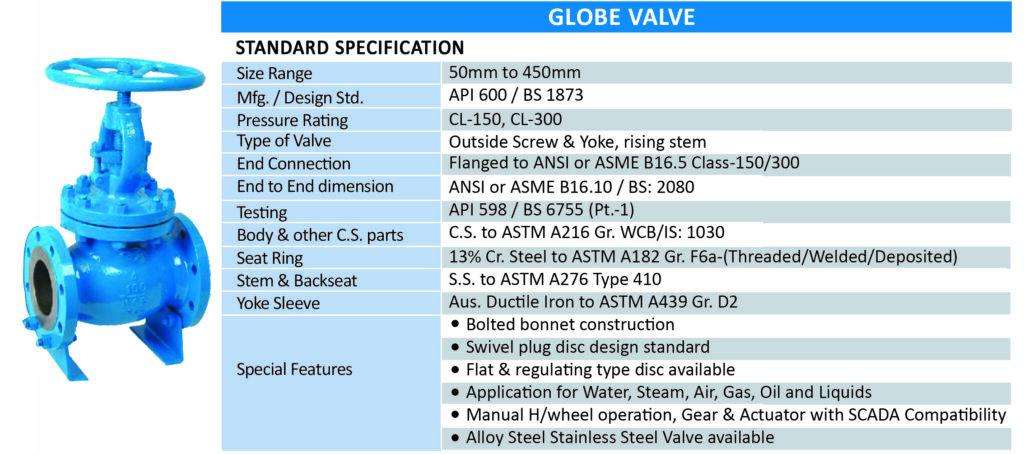

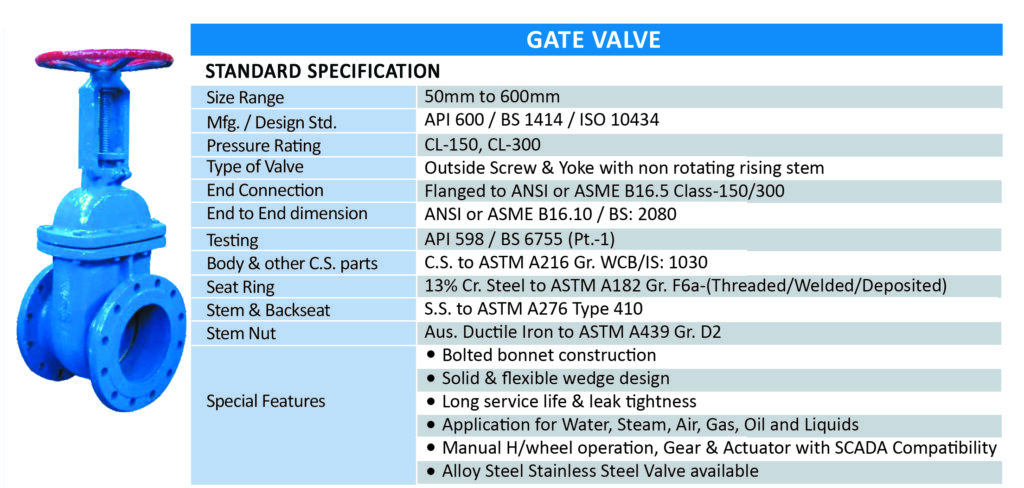

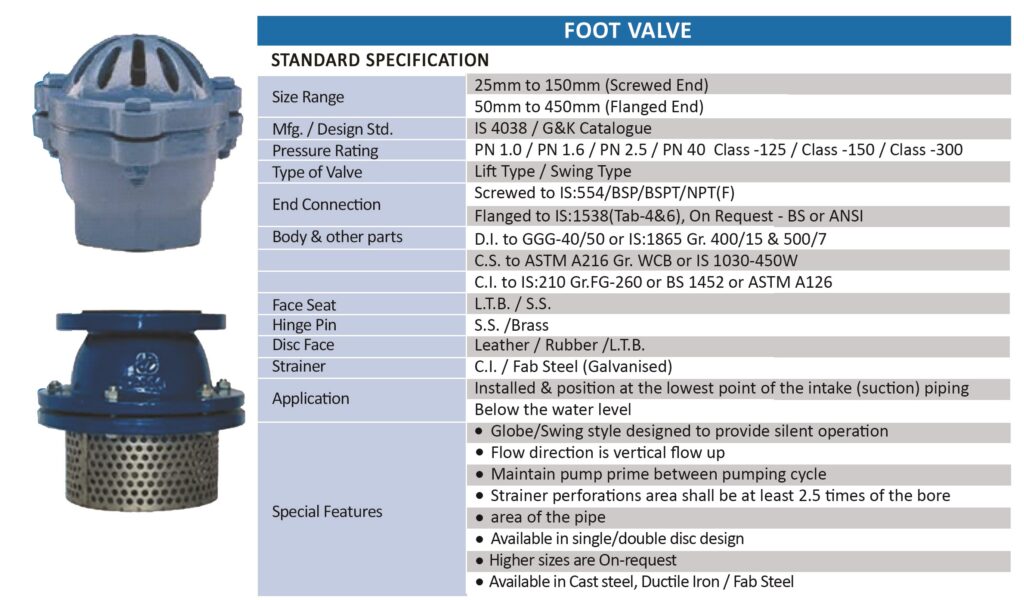

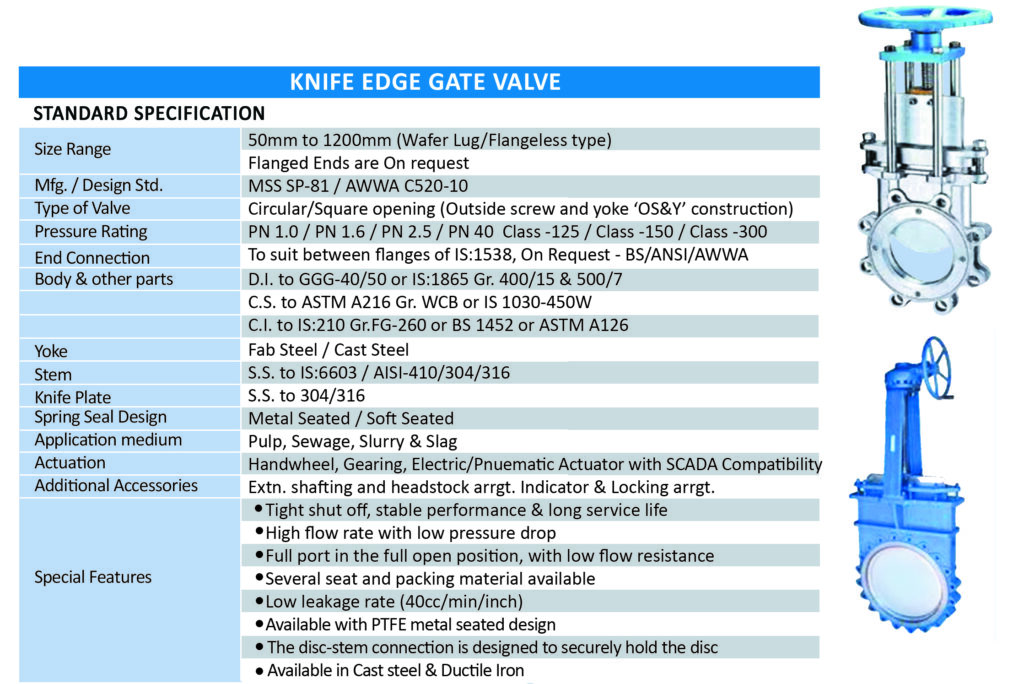

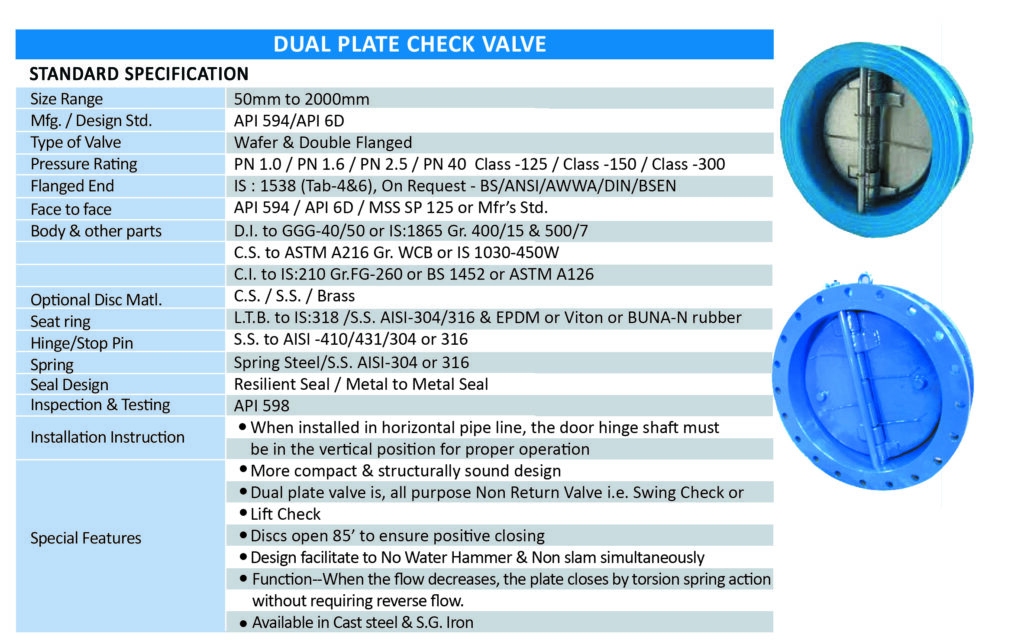

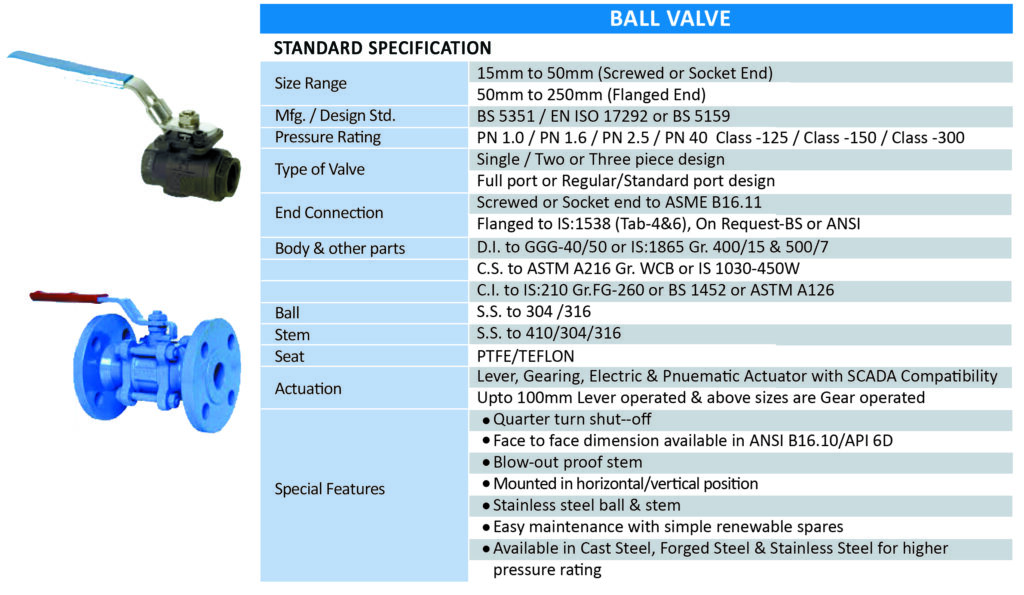

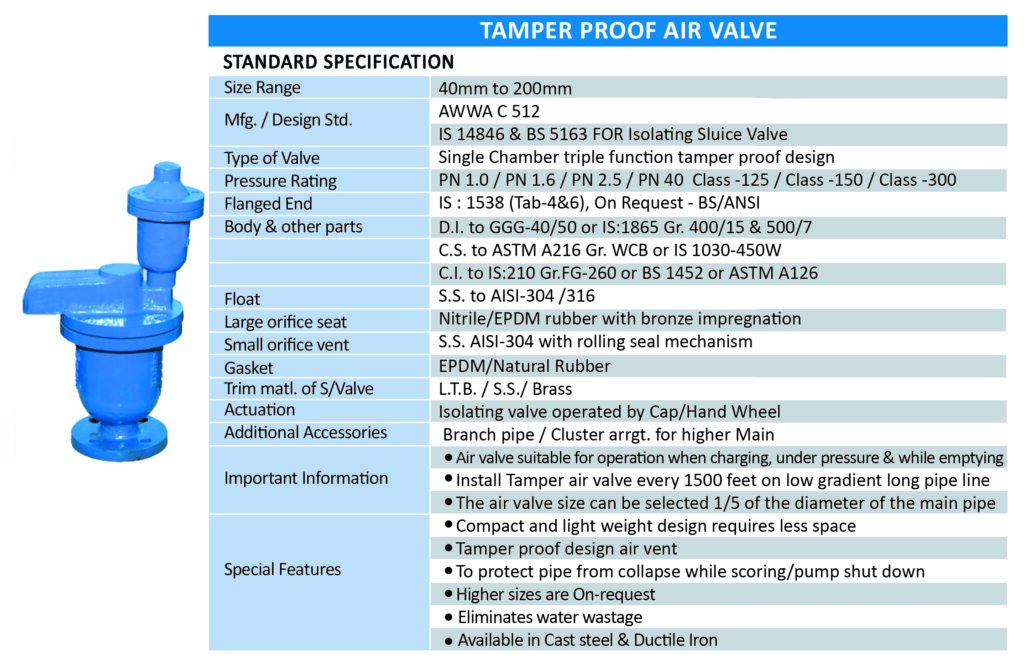

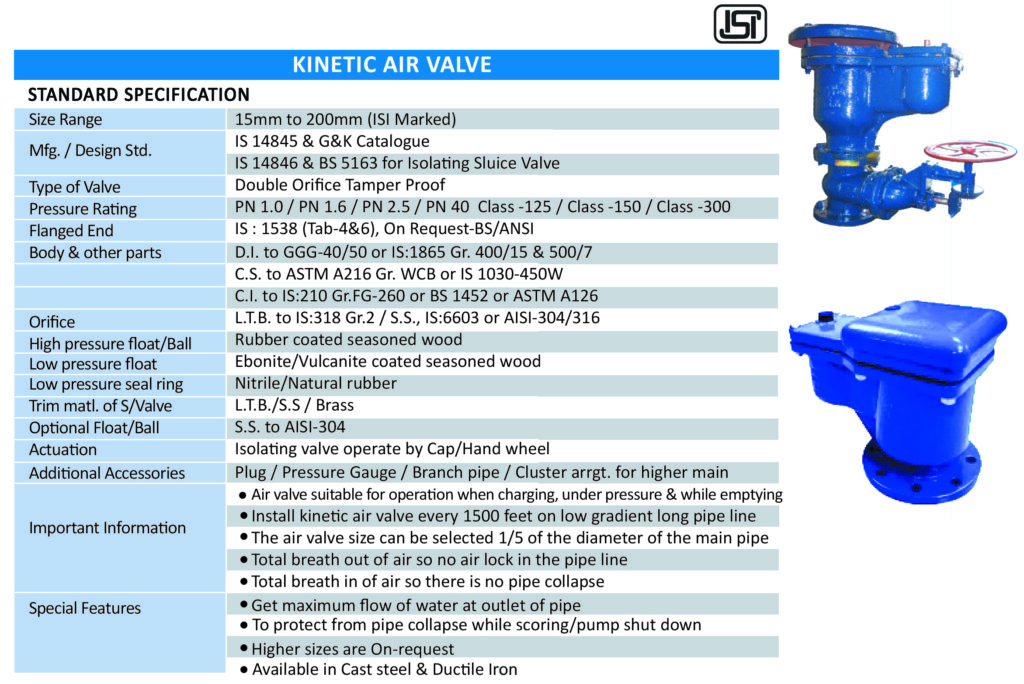

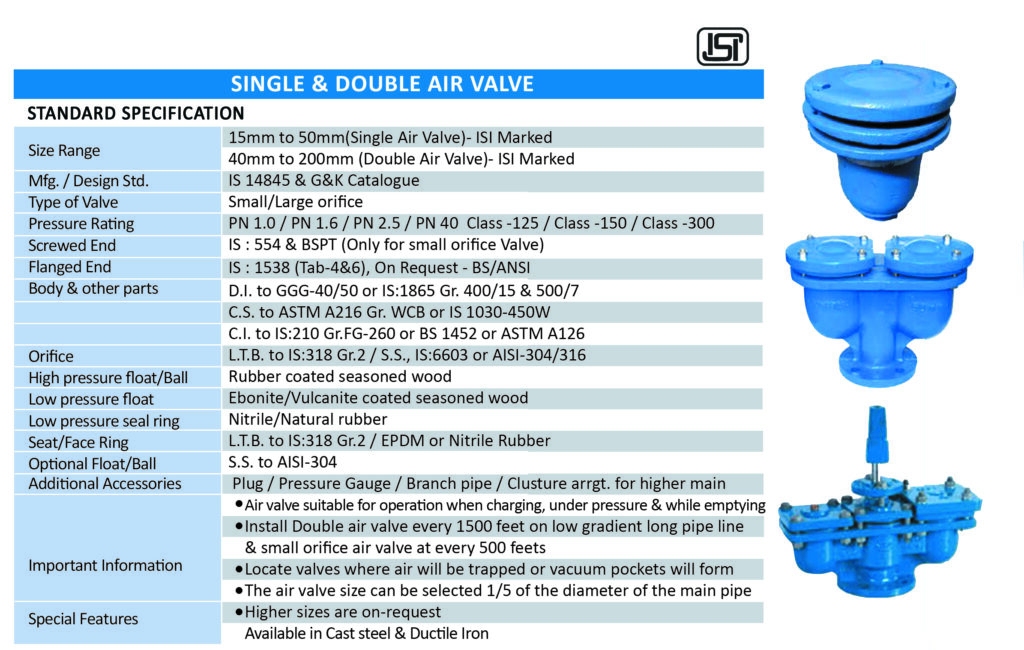

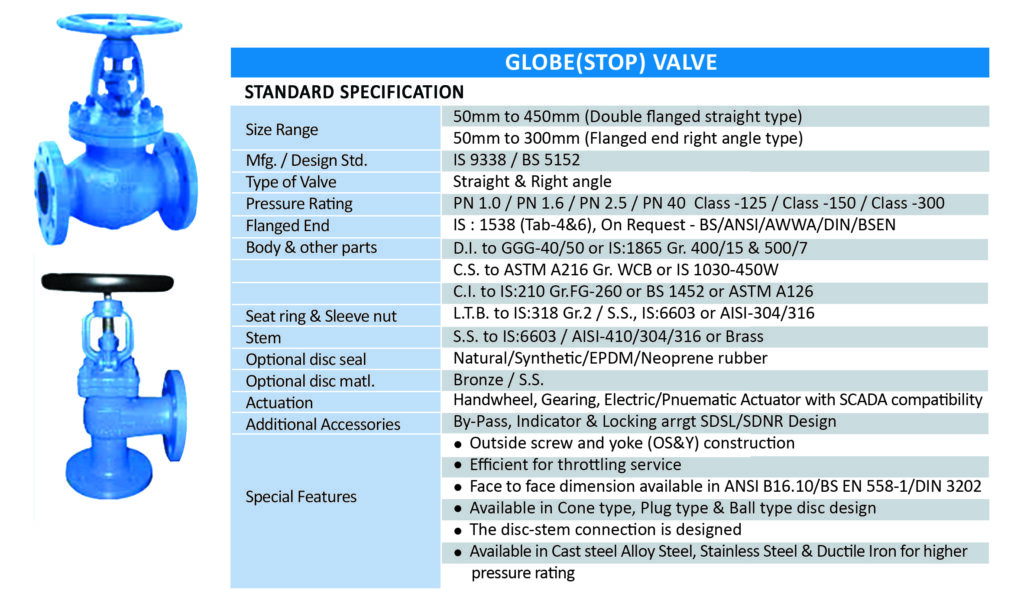

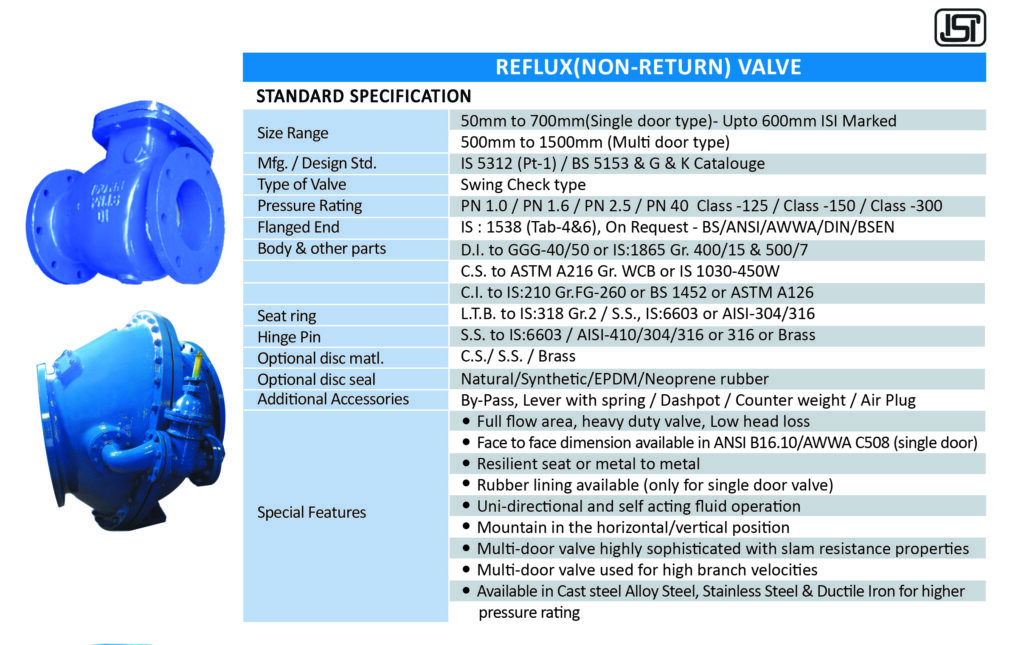

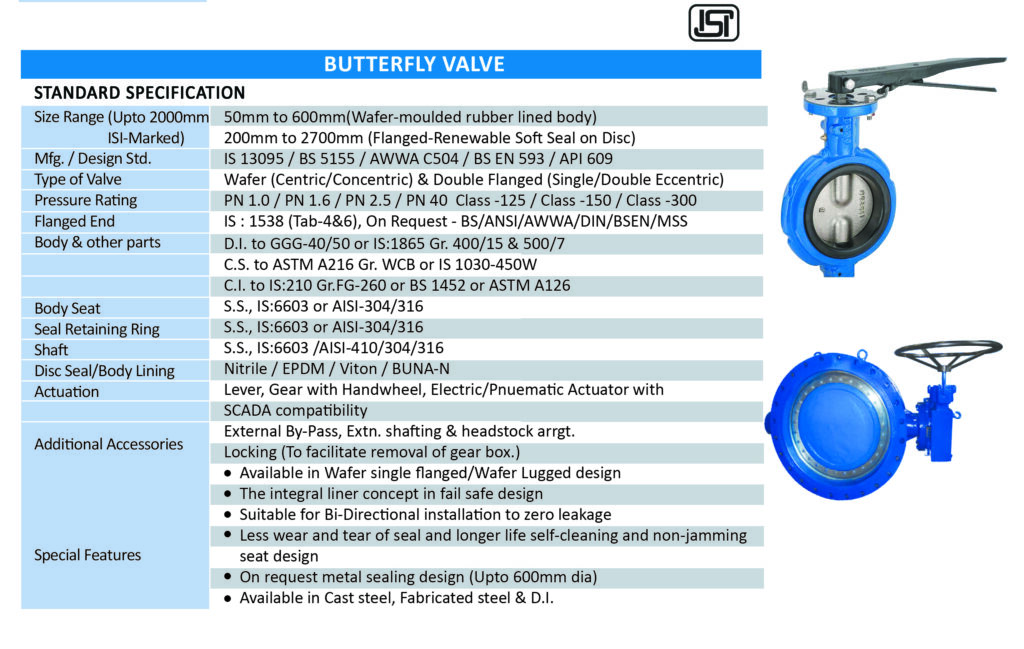

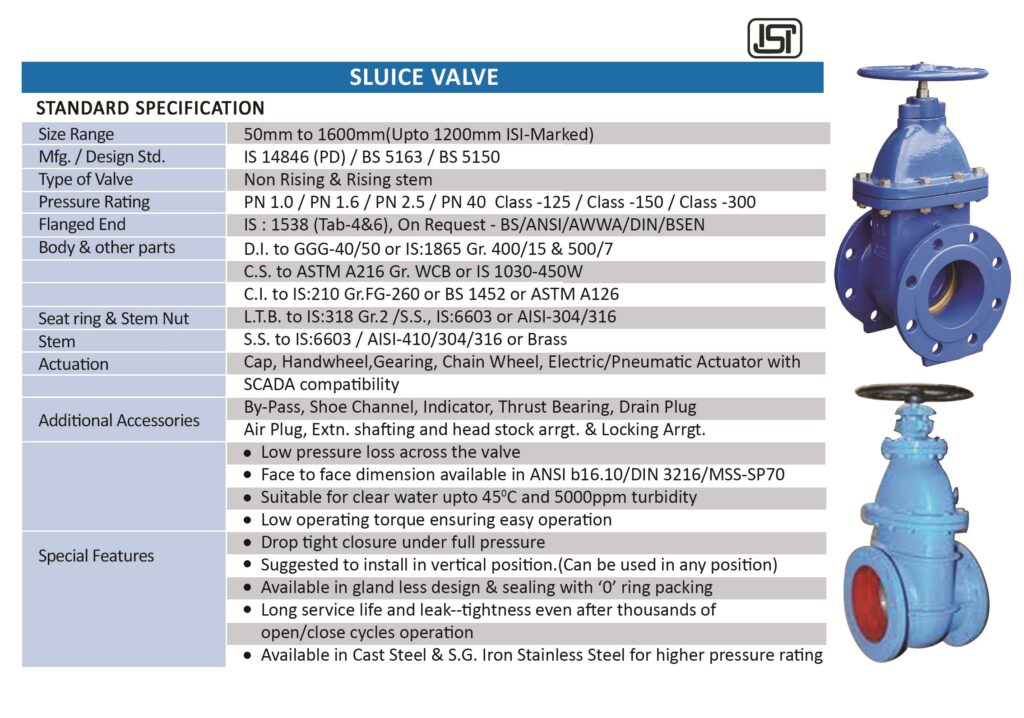

- Valve components

- Brackets and mounting structures

We know you want strength, you want stability and you want cost-effectiveness. Cast iron gives you everything together.

Can you work with custom designs?

Yes, we regularly manufacture castings based on client drawings.

Do you also offer stainless steel casting?

Yes, for corrosive or demanding environments.

How do you manage quality?

Through checks during production, not just at the end.