The Complete Guide to Cast Steel Castings: Types, Uses & Advantages

When you work around castings long enough, you start noticing one thing: people don’t always understand what goes into choosing the right metal. Many folks pick something because it “sounds strong,” but most of the time, strength alone doesn’t solve a problem. So let me break things down the way we usually explain it at the shop when a client walks in and says, “I need something reliable, but not overpriced.” That’s usually when we talk about Cast Steel Castings.

If you’ve been around this industry, you already know Cast Steel stands for carbon steel. It’s been one of the most dependable materials for decades. It’s not fancy, and it doesn’t need to be. It just works. When you pour molten carbon steel into a mould, cool it, and machine it right, you get a component that takes load, shock, pressure — whatever your equipment throws at it.

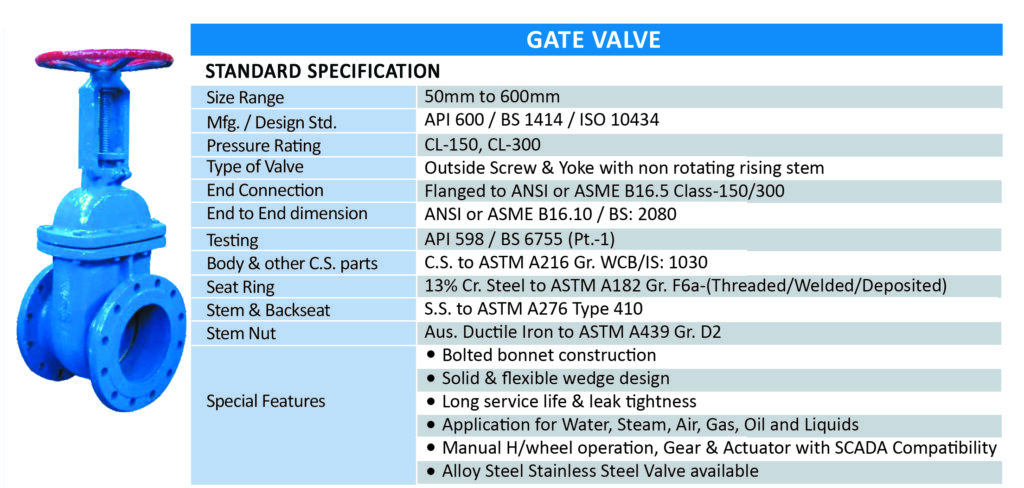

At our company, we’ve seen Cast Steel go into valves, pumps, heavy machinery, and structural systems. Some of those parts run for years with barely any complaints. That’s the beauty of carbon steel: it behaves predictably.

What Cast Steel Castings Really Are

Forget complicated definitions. These castings are simply parts made by pouring molten carbon steel into a mould. The amount of carbon in the steel changes how tough, ductile, or hard it becomes. That’s pretty much the deciding factor behind where each grade is used.

We deal with three broad categories:

1. Low-Carbon Steel Castings

These are easy to shape and weld. You use them when you don’t need extreme hardness. Brackets, housings, linkages — that kind of stuff. If someone needs flexibility in fabrication later, this grade usually makes sense.

2. Medium-Carbon Steel Castings

Now this is the middle ground. Stronger than low carbon but still workable. We see these in automotive parts, small machine components, and moderate-load structures.

3. High-Carbon Steel Castings

If hardness is your main goal, this is where you look. These are used in wear-heavy parts — pins, wheels, and impact components. Welding them isn’t fun, though, so we usually recommend getting the dimensions right at the casting stage itself. That’s the honest breakdown, not the textbook version.

Why Carbon Steel Castings Are Still Used Everywhere

People often ask why, with all the fancy alloys in the market, carbon steel still dominates. The answer is simple: it’s tough, it’s dependable, and it doesn’t eat your entire budget.

Strength That Holds Up

Carbon steel can take a load and shock without giving up. Machinery folks like it because it doesn’t fail suddenly; it gives signs before things get worse.

Cost That Makes Sense

You could go with exotic metals, but most applications don’t need them. These Castings give you performance without unnecessary expense — and that matters when you’re producing thousands of components.

Versatility

Carbon steel handles machining well. If your design needs fine details or unusual shapes, casting in carbon steel usually works.

How Cast Steel Castings Are Actually Made

You’ll see a lot of diagrams online, but the real-life process has more noise, dust, and heat than those drawings suggest. Still, the main steps stay the same:

Pattern

We start with a replica of the final part.

Moulding

Sand mould, mostly. Sometimes, investment casting for tighter accuracy.

Melting

Carbon steel gets heated in the furnace.

Pouring

We pour it into moulds. Timing matters a lot here.

Cooling

This part decides how the grain structure behaves.

Cleaning + Machining

Removing runners and gates and doing the finishing touches.

Good casting is not about machines alone. It’s about the people who know when metal “sounds right.” Anyone who works in a foundry knows exactly what I mean.

Cast Steel Castings vs. Stainless Steel Castings — Choose Carefully

Now, people often confuse Carbon Steel Castings with Stainless Steel Castings, assuming both can work interchangeably. They don’t.

Here’s the straight answer:

Choose Carbon Steel Castings when:

- You need load-bearing strength

- You want cost-efficient performance

- Corrosion isn’t a major threat

- You expect impact or vibration

Choose Stainless Steel Castings when:

- You deal with water, moisture, or aggressive chemicals

- Hygiene matters (food, pharma, dairy plants)

- You need better temperature stability

- Your equipment must resist rust for years

We manufacture both, and even then, nine out of ten times, we see customers pick the wrong one initially — mostly because stainless steel “sounds superior.” It isn’t superior; it’s just suited for different situations.

Where Cast Steel Castings Are Used in Real Industry Work

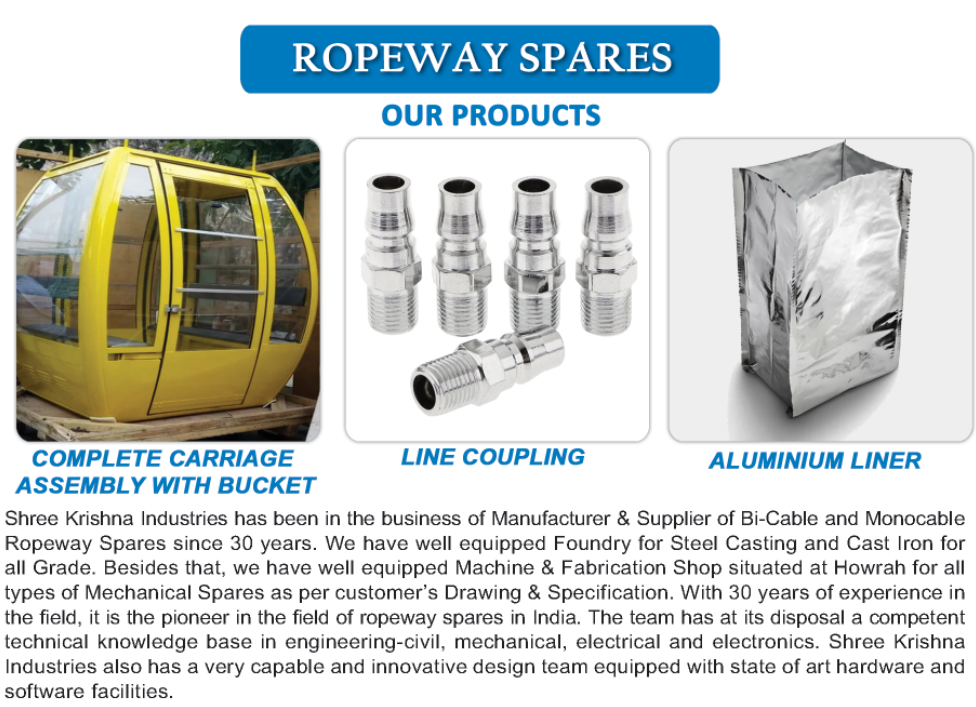

At Shree Krishna Industries, we’ve supplied Carbon Steel Castings for years, and the applications hardly change because the demand stays high:

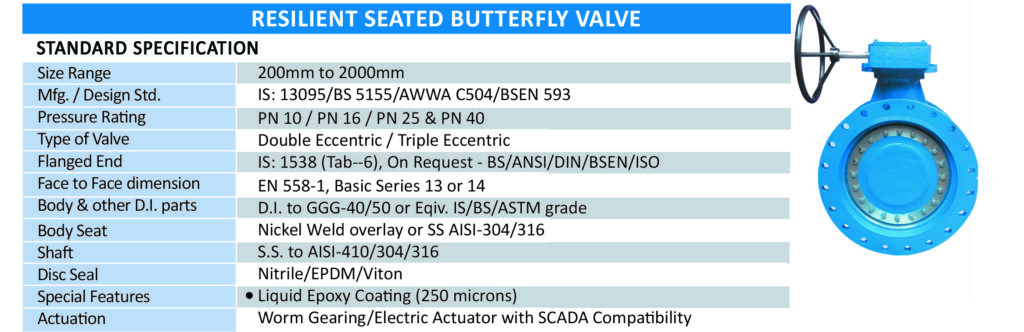

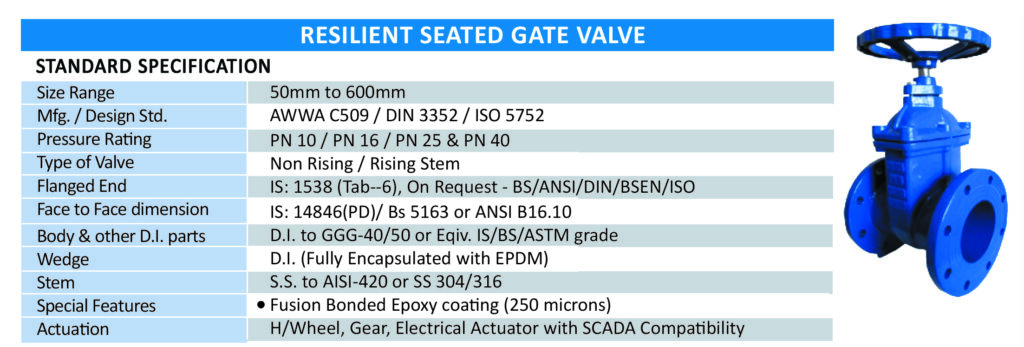

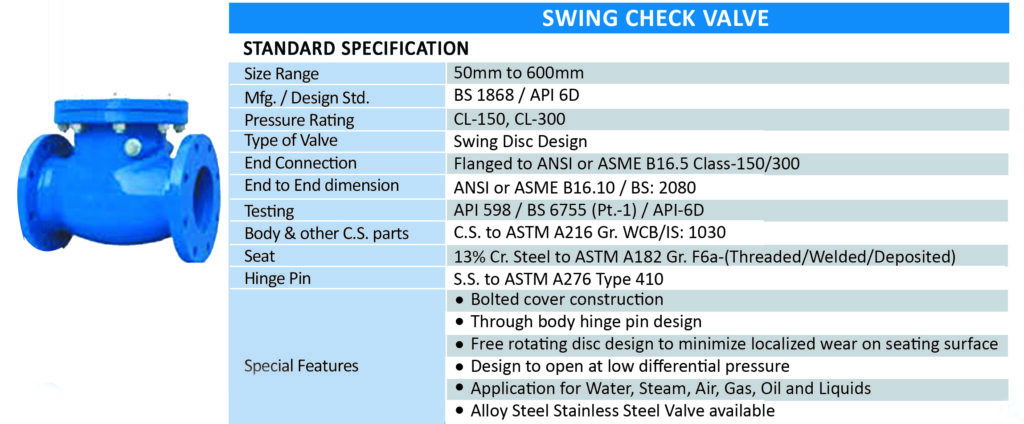

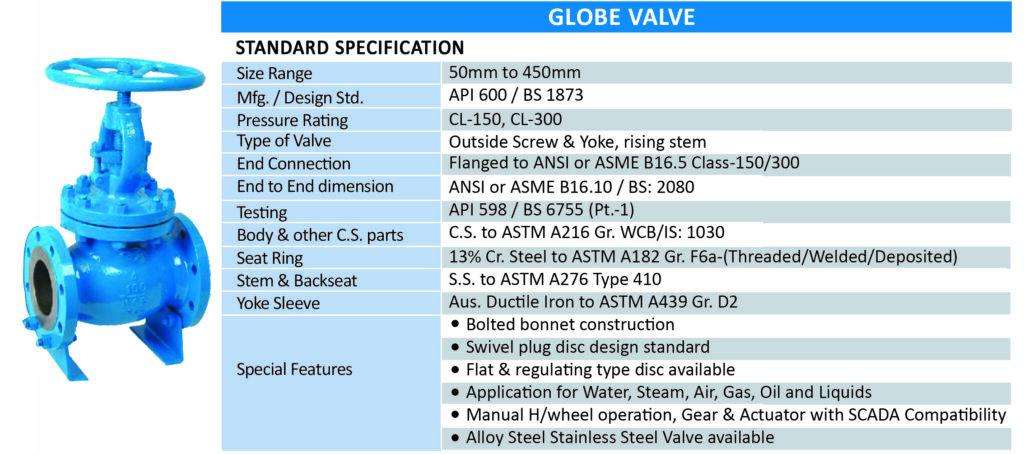

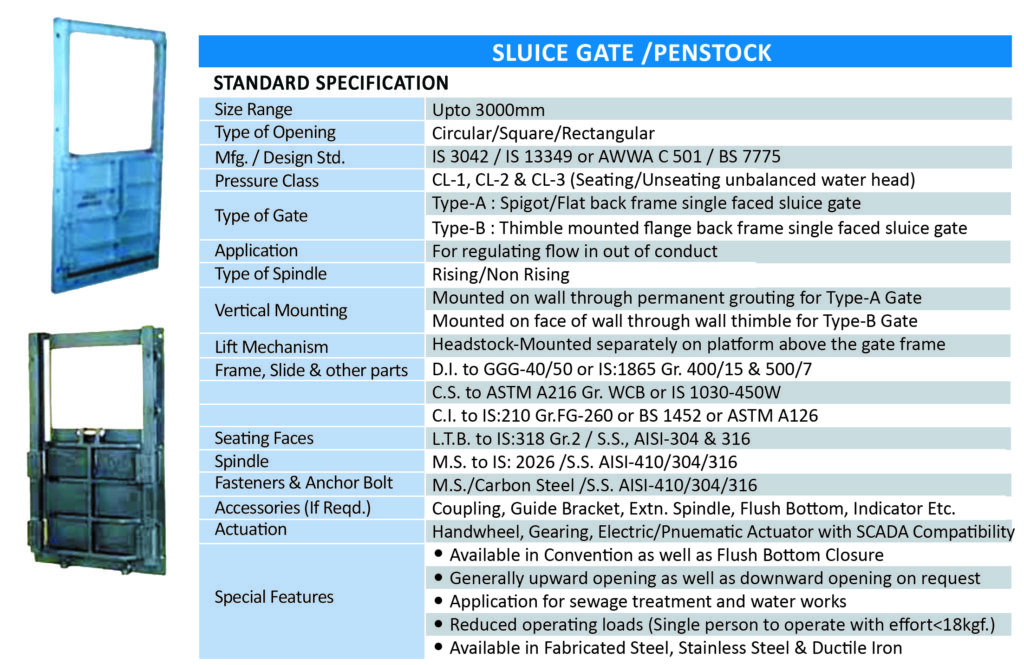

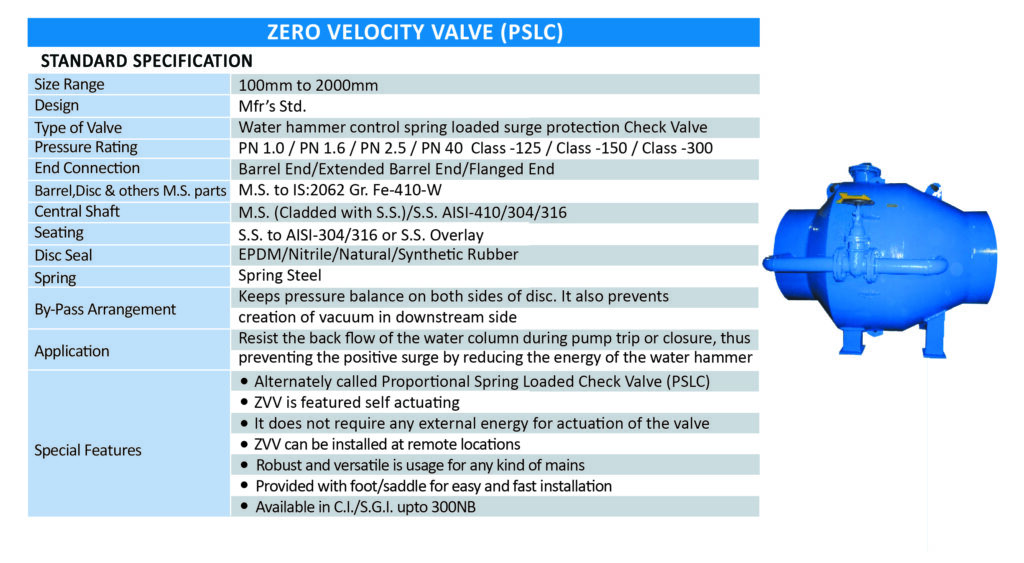

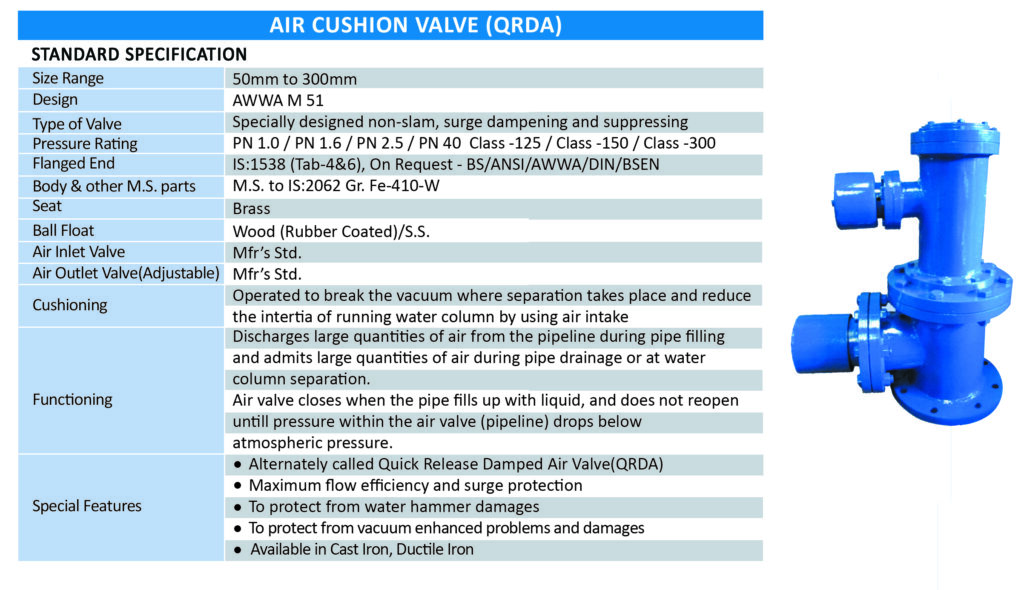

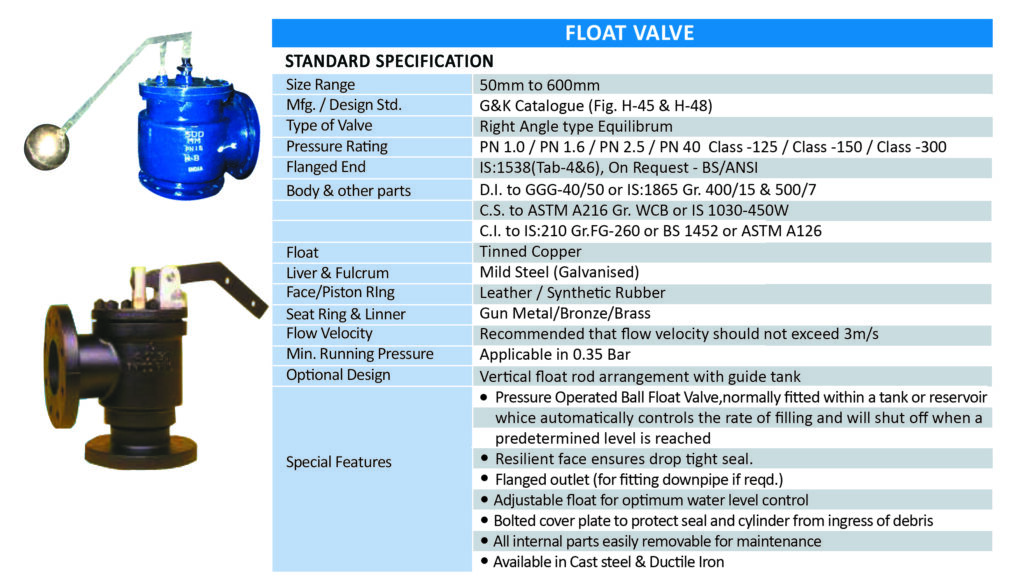

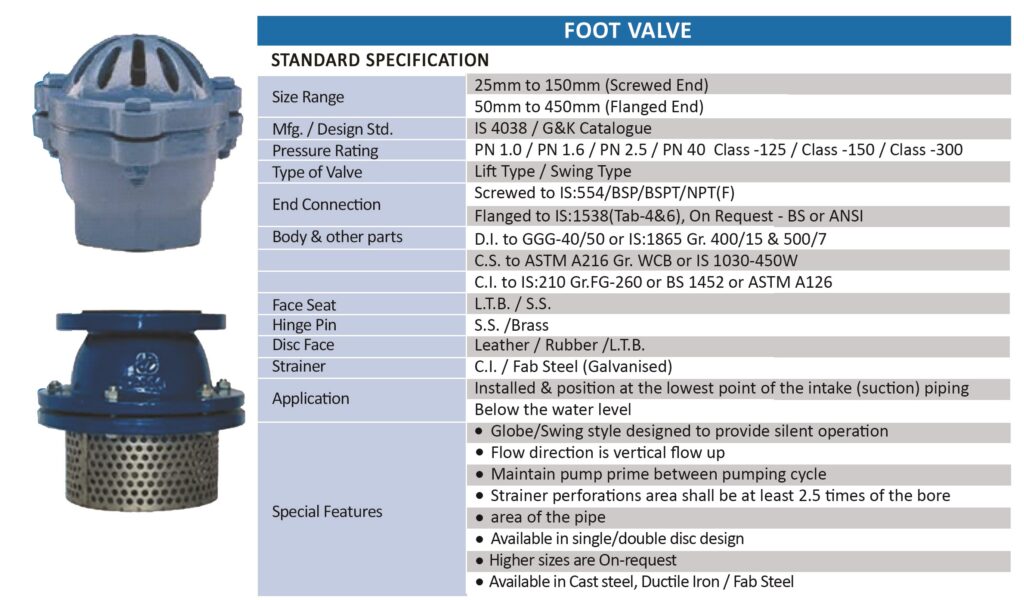

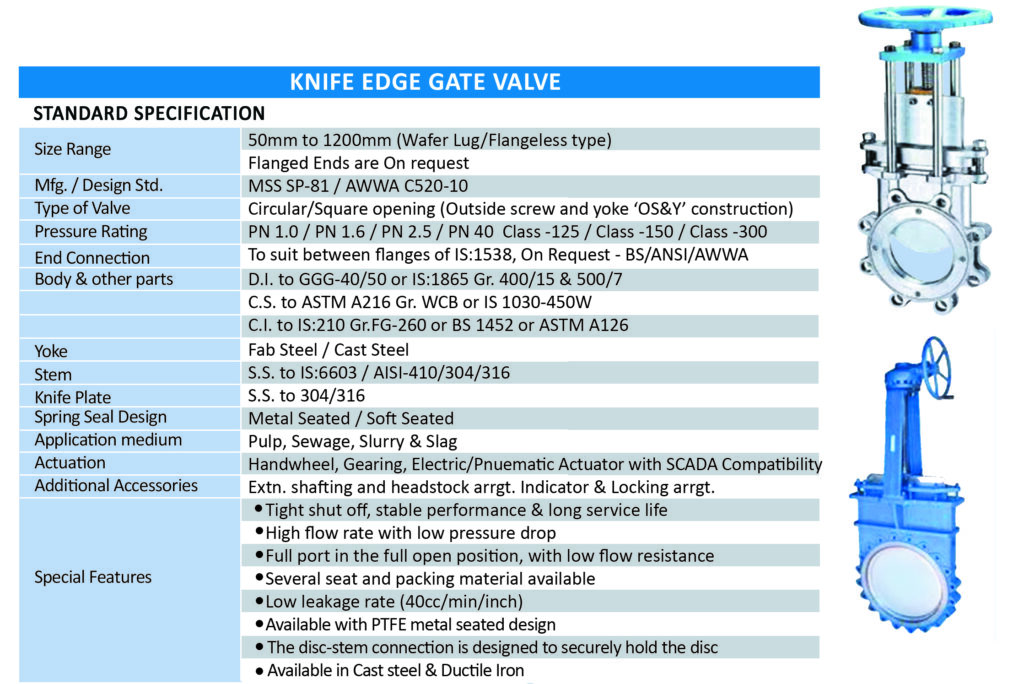

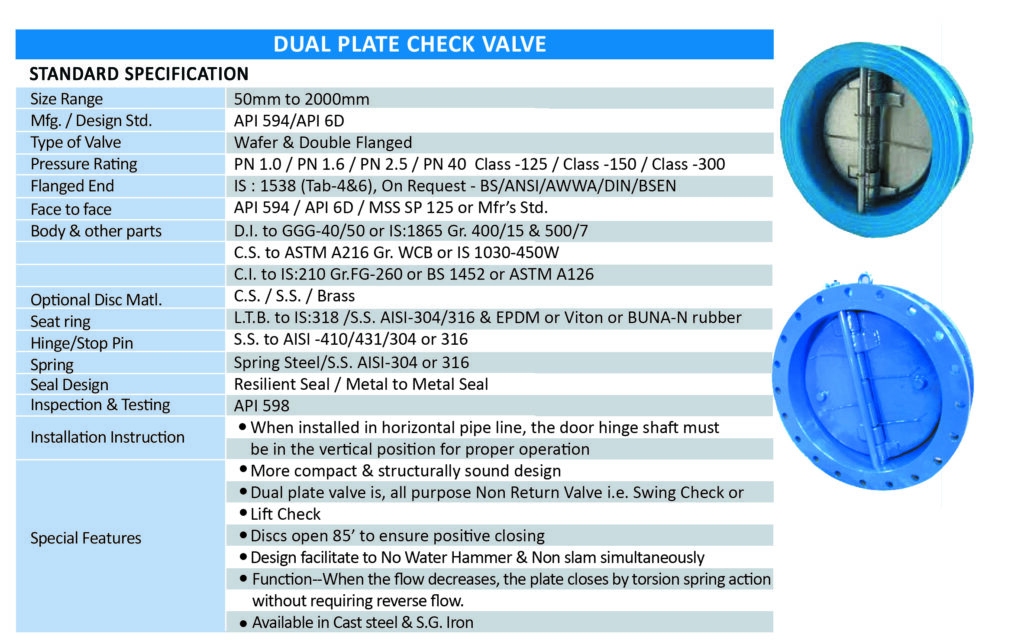

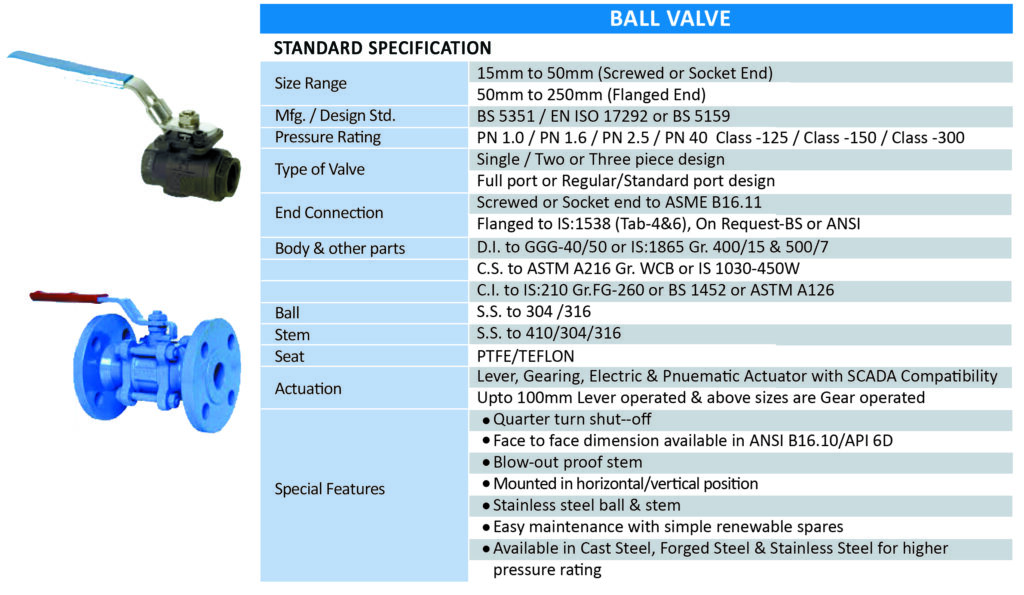

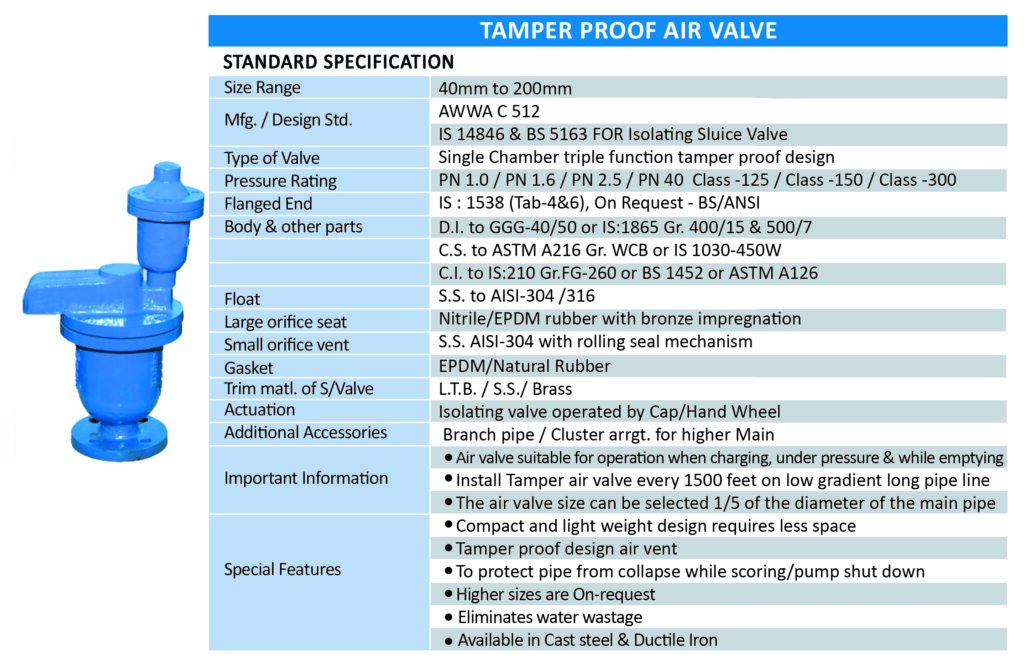

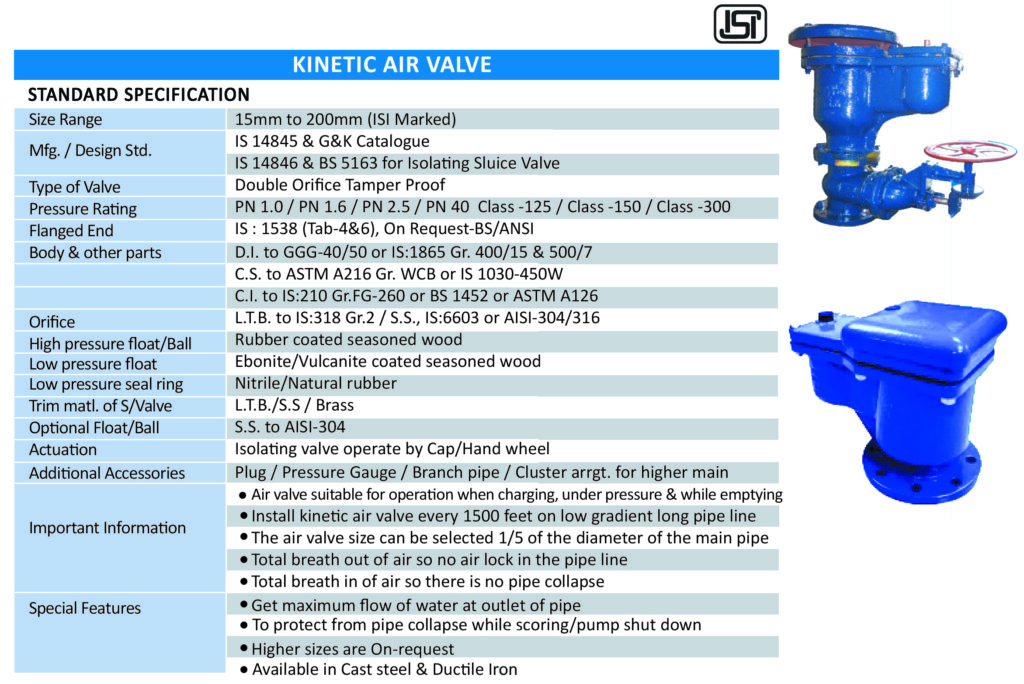

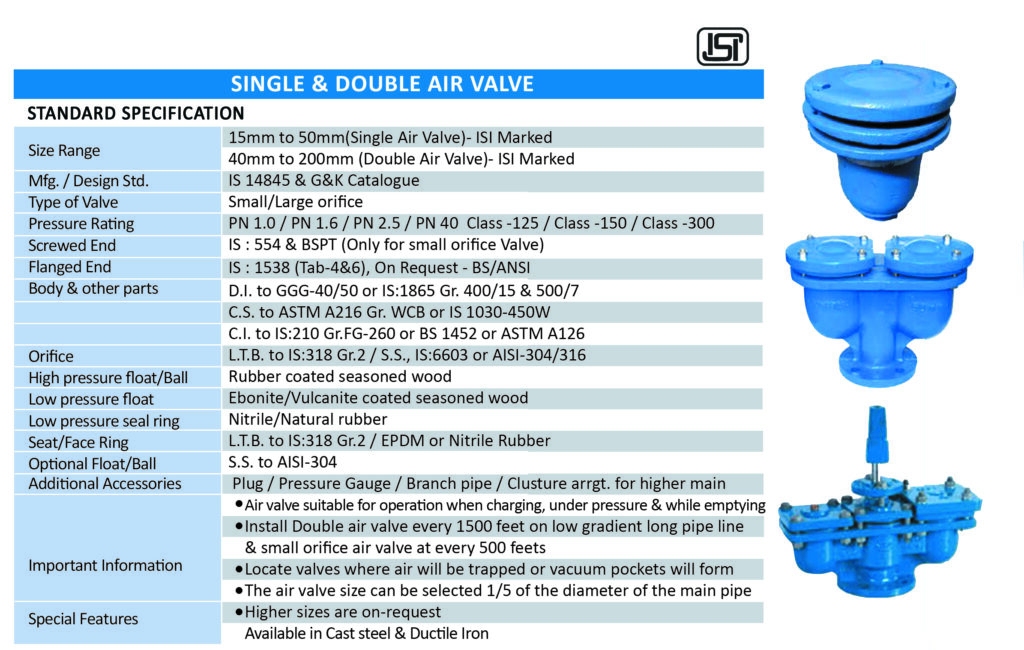

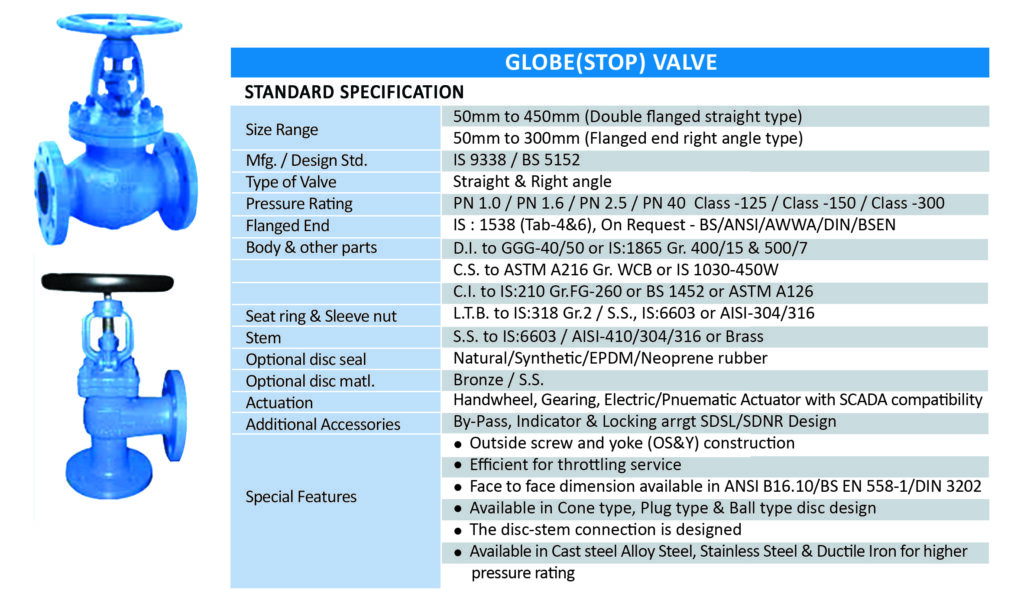

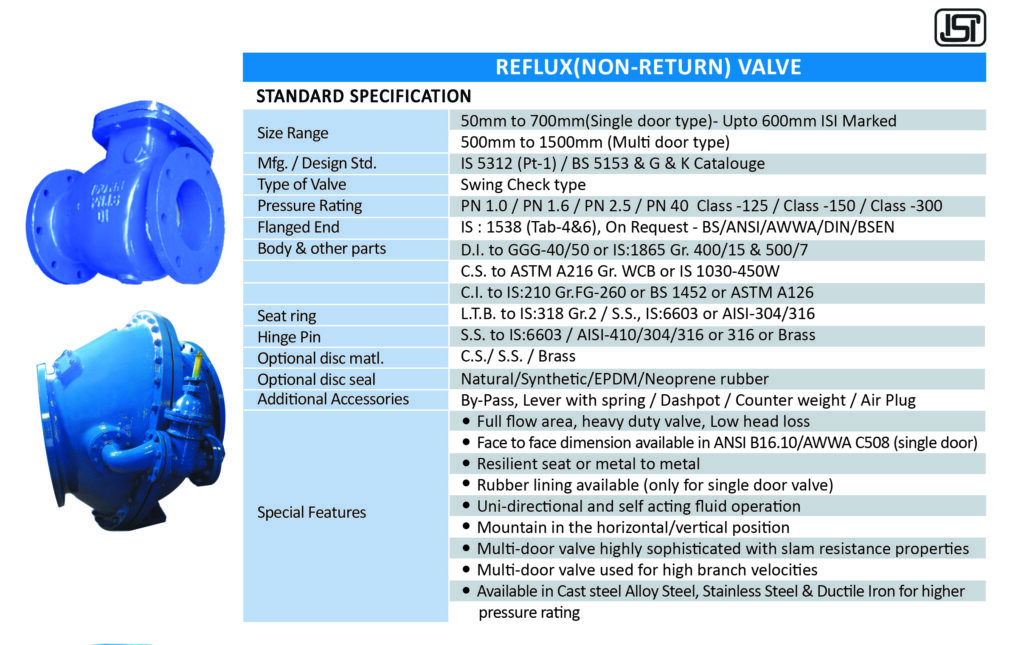

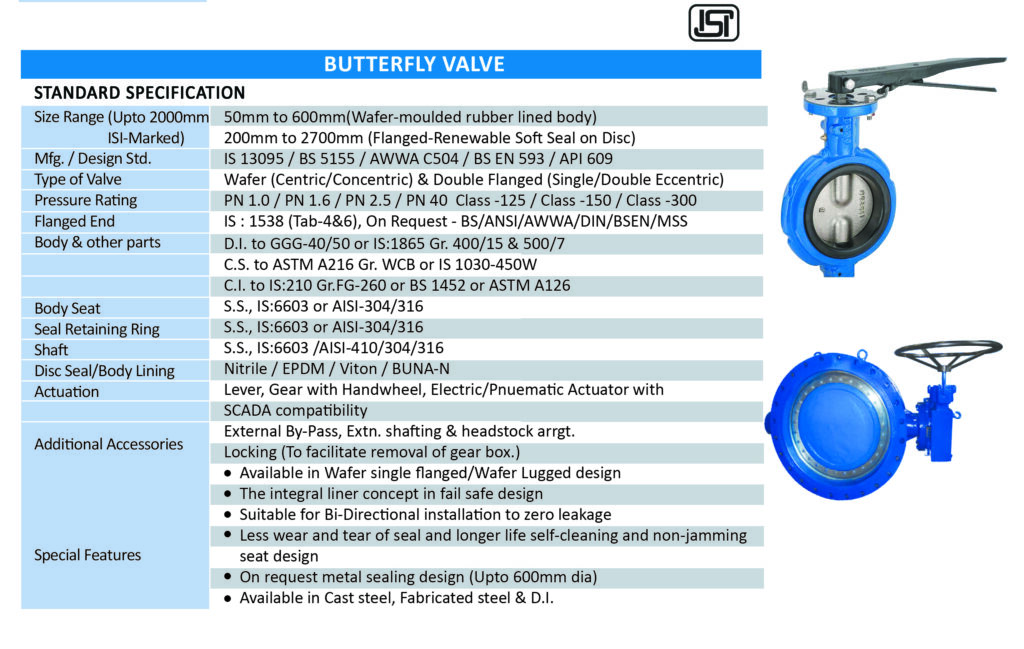

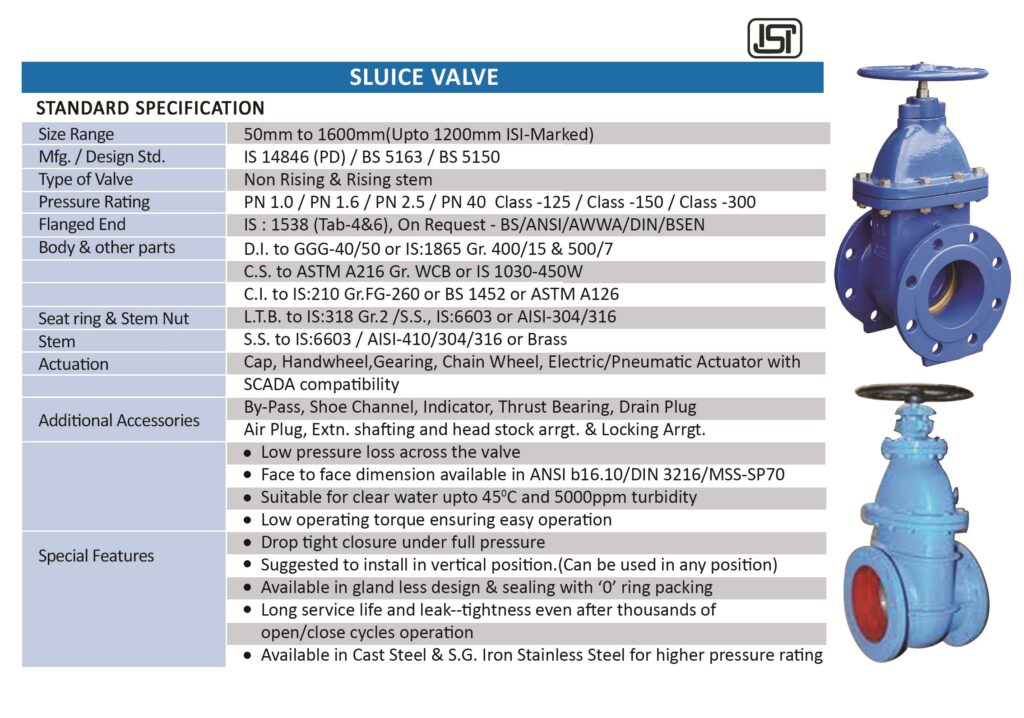

Valves and Fittings – Cast Steel handles internal pressure well.

Pump Parts – Strong and predictable under load.

Machine Housings – Heavy equipment relies on this.

Automotive Components – Frame parts, support structures.

Infrastructure Hardware – Anything needing toughness.

If you’ve ever visited a plant or construction site, chances are you’ve seen Cast Steel components everywhere — you just didn’t know it.

Why Many Clients Prefer Working With Us

I’ll keep this honest. Customers usually stay with us because we don’t oversell. If carbon steel is enough, we say so. If they need stainless, we say that too. Over the years, we’ve built our work around a simple idea: give people exactly what their application demands.

Some reasons businesses trust us:

- Consistent cast quality

- Accurate dimensions

- Experienced foundry team

- Wide range of Cast Steel and Stainless Steel Castings

- Reliable delivery schedules

This is the kind of work you can’t fake. You earn it over the years.

FAQs — Straight Answers

1. Are Cast Steel Castings suitable for outdoor use?

Yes, as long as the environment isn’t too corrosive. If it’s exposed to seawater or chemicals, stainless steel is safer.

2. Will stainless steel last longer than carbon steel?

In corrosive conditions, yes. Otherwise, both hold up well depending on the load and use.

3. Can Carbon Steel Castings be customised?

Yes. At Shree Krishna Industries, most of our clients bring drawings, and we cast exactly to spec.

4. Is carbon steel cheaper than stainless steel?

Usually. That’s one reason it’s so widely used in heavy engineering.

5. Which industries rely on Cast Steel castings the most?

Machinery, construction, automotive, pump manufacturing, and valve producers.