Understanding Ductile Iron Castings: Strength, Flexibility & Applications

When you hear Ductile Iron Castings, you might think “just another metal part.” But there’s a lot more behind those letters — and as someone involved in manufacturing or engineering, you’ll quickly see why these castings are often the go-to solution when strength, reliability, and versatility matter. At our casting facility, we don’t just supply castings — we build confidence in what you install.

You know your needs better than anyone. We respect that.

What Are Ductile Iron Castings (and How Do They Differ)

“DI” stands for Ductile Iron — a form of cast iron engineered to overcome many of the traditional limitations of conventional cast iron. Whereas conventional cast iron often suffers from brittleness (especially under tensile stress), ductile iron uses a microstructure that gives it both strength and ductility.

- In cast iron in general, carbon content is relatively high, which makes the material hard but often brittle.

- Ductile iron (DI) changes the internal structure (graphite nodules rather than flakes), which significantly improves properties such as tensile strength, impact resistance, and ability to deform without breaking.

Because of that, ductile iron castings give you a “best of both worlds” — the robustness and durability of iron, but with a level of resilience and toughness that lets them handle stress, impact, and fatigue much more reliably than brittle cast iron.

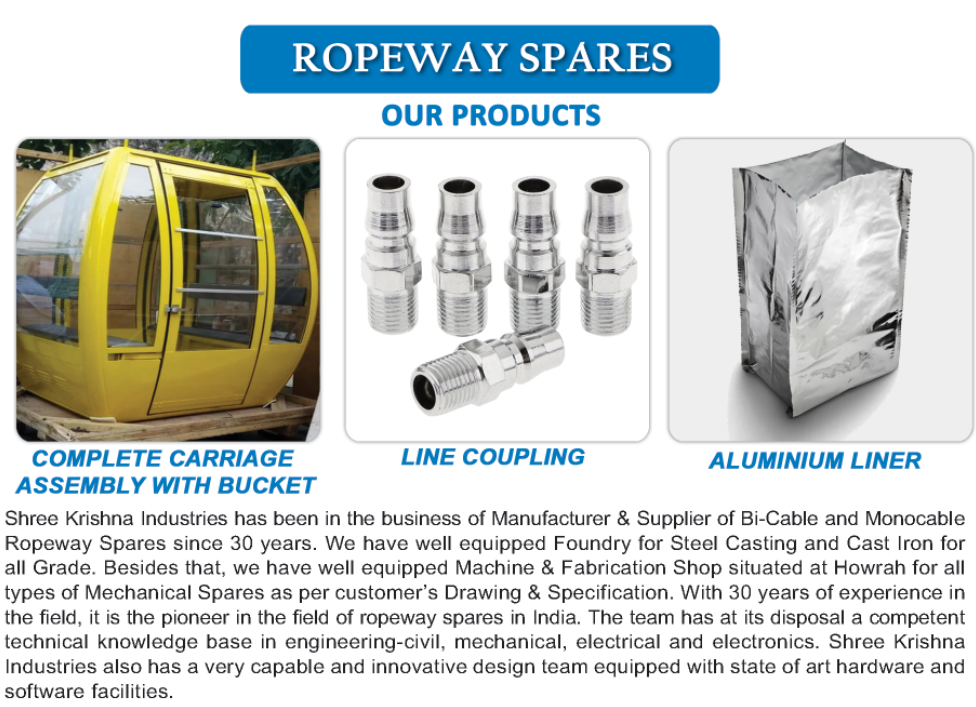

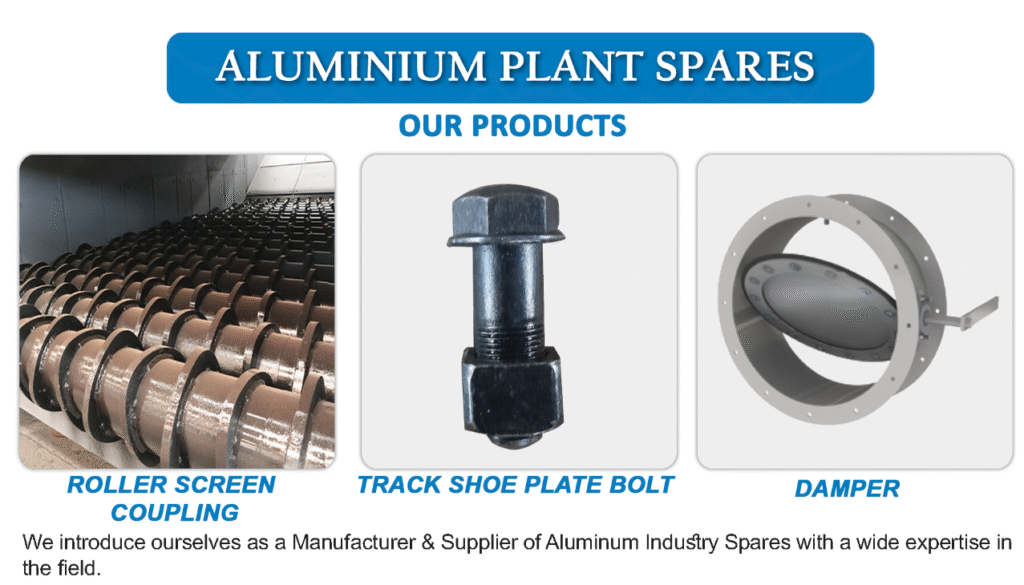

That’s why many foundries (including ours) choose ductile iron castings when they want heavy-duty parts that also must last and perform under challenging conditions. At Shree Krishna Industries’ foundry, we deal not only in these castings but also in castings made from cast iron, cast carbon steel, alloy steel, stainless steel, and non-ferrous materials.

Cast Steel Castings & Cast Iron Steel Castings / Steel Castings — How They Fit In

Sometimes, Ductile Iron may not be enough — especially when your component must endure dynamic loads, high pressure, or extreme conditions. That’s where cast steel or cast iron-steel castings come into play.

How Steel Castings Take Shape

When you look at cast steel castings, you’re really looking at components born from molten steel. We heat carbon or alloy steel until it flows like liquid fire, and then we pour it into moulds that shape your final part. You get strength from the very beginning because steel behaves differently from iron.

Steel Castings Built for Heavy Work

You already know how iron castings work, but steel takes things a step further. Steel castings give you more toughness, better shock resistance, and superior performance when your machines keep moving nonstop. When your application faces dynamic loads, steel simply handles the pressure with more confidence.

Choosing the Right Steel Casting

And we don’t stop at one type. Steel castings come in several families — carbon steel, alloy steel, and stainless-steel castings. Each one serves a different purpose. You choose based on chemical composition, strength expectations, corrosion requirements, or the kind of environment your part must survive. We help you navigate those choices so you never feel lost.

Steel vs Cast Iron: The Winning Difference

When you compare steel to regular cast iron, the difference becomes obvious. Steel gives you more ductility, higher tensile strength, and far better weldability. It holds up under wear, vibration, and fatigue. That’s why so many industries depend on steel when reliability cannot be compromised.

Wide Range of Casting Options

At our casting facility, we value choice because your needs aren’t the same each time. We work with DI (Ductile Iron), Cast Iron, Cast Carbon Steel, Alloy Steel, and Stainless Steel. This flexibility lets us build parts that match your real-world challenges — whether you want cost-effective durability or heavy-duty performance.

Ductile Iron That Supports Your Workload Smoothly

Now, when we talk about Ductile Iron Castings, we talk about materials that feel dependable in your hands. Let’s move to what you actually experience once these parts reach your site. These castings offer a powerful combination of strength and flexibility. They don’t just carry load — they absorb impact, handle vibration, and stay steady when mechanical stress keeps trying to push them over the edge.

That’s the beauty of Ductile Iron . It works with you, not against you. And when you install it, you feel the difference in real time.

Why You (and We) Value Ductile Iron Castings — Strength, Flexibility & Reliability

Strong but resilient:

Ductile iron castings effectively reduce fatigue and absorb shock in addition to withstanding large loads. Because of this, they are especially appropriate for components that are frequently subjected to impact, vibration, or mechanical stress.

Cost-effective alternative to steel (in many cases):

While steel castings give premium performance, Ductile Iron often gives enough strength and durability at a lower cost — which matters if you’re producing at scale or managing budgets.

Great for complex shapes and heavy-duty parts:

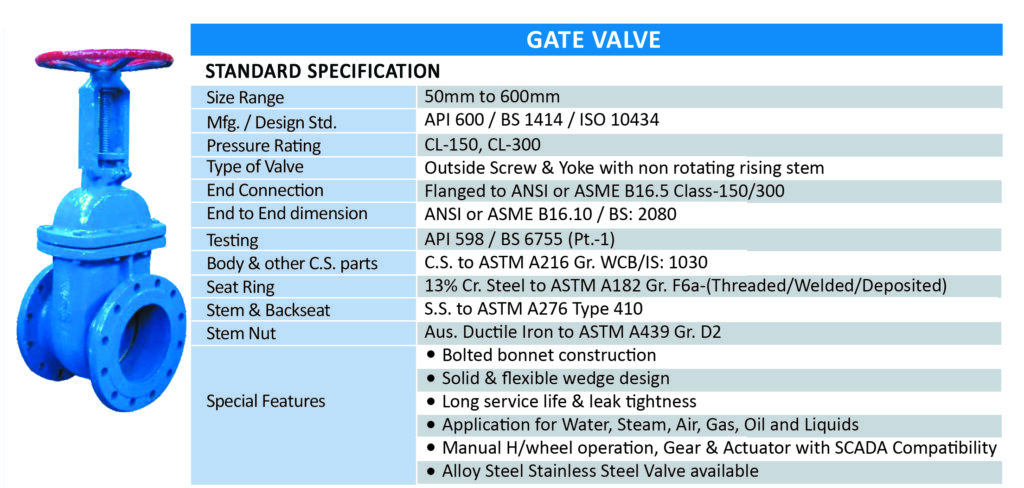

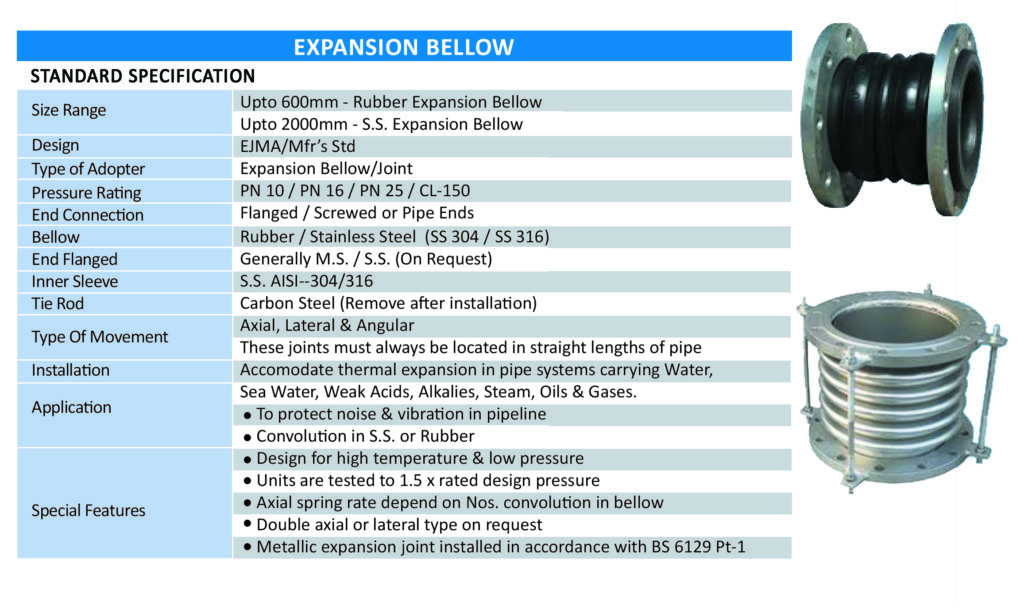

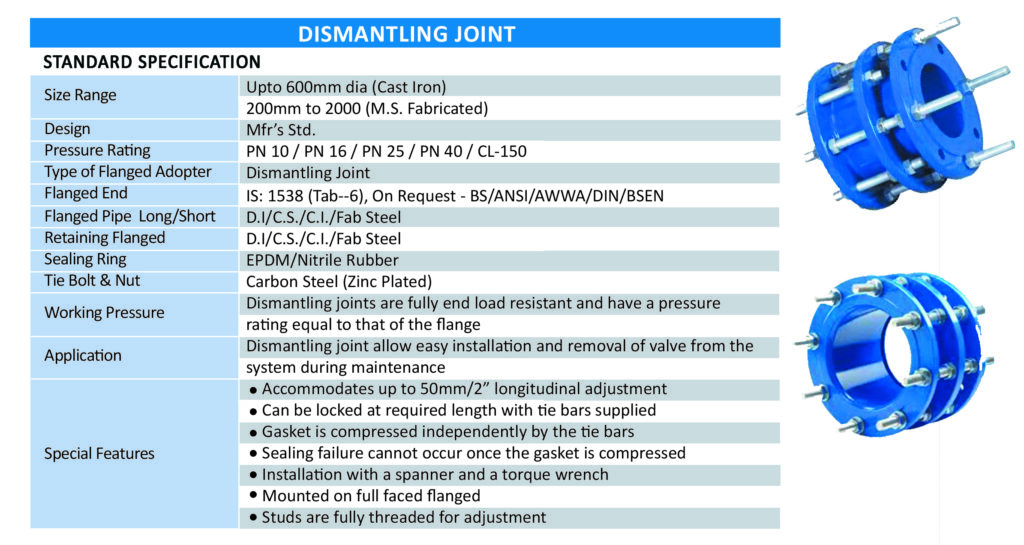

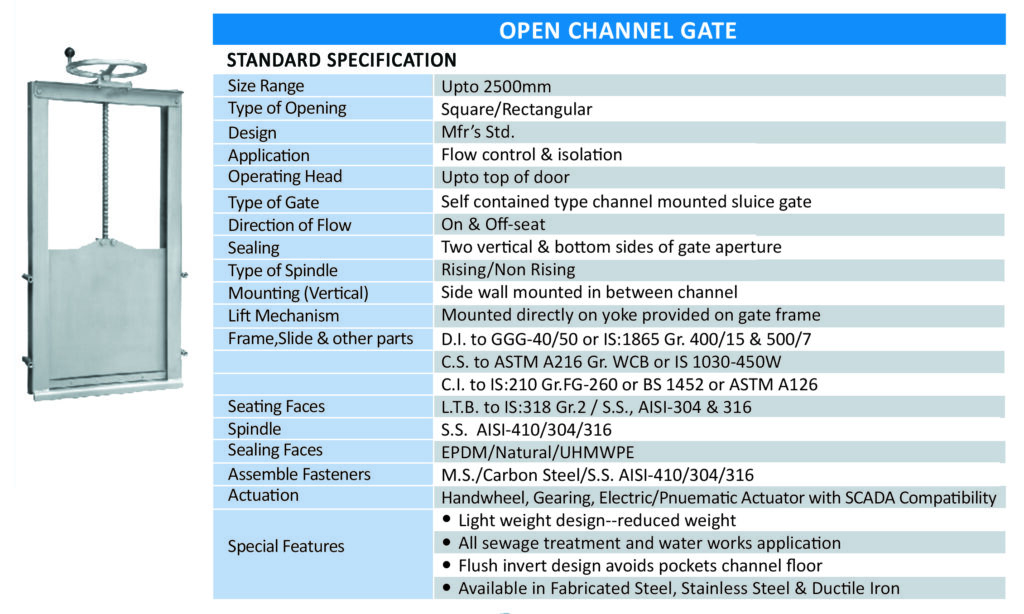

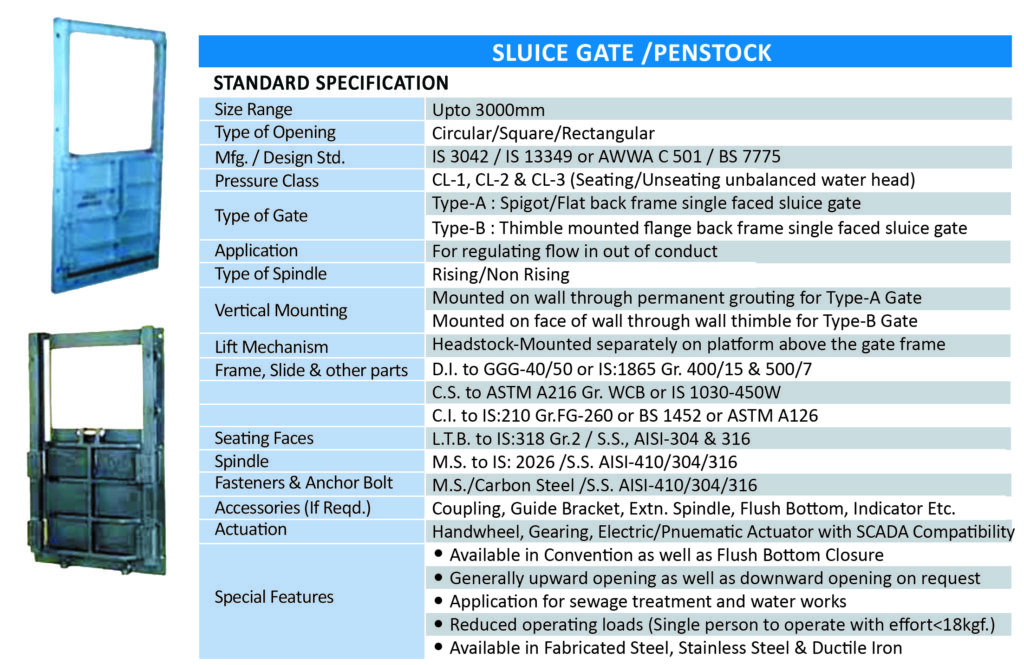

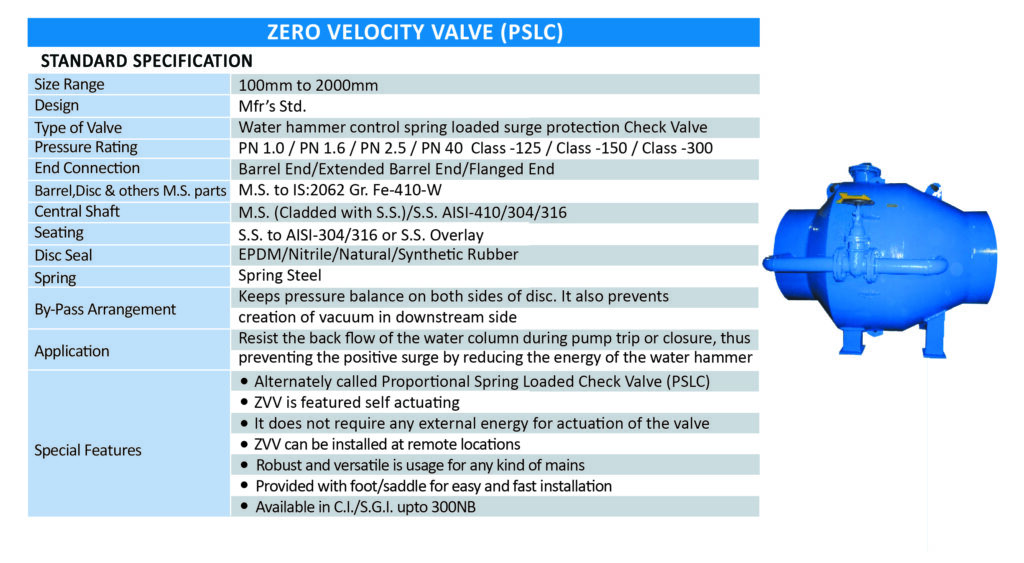

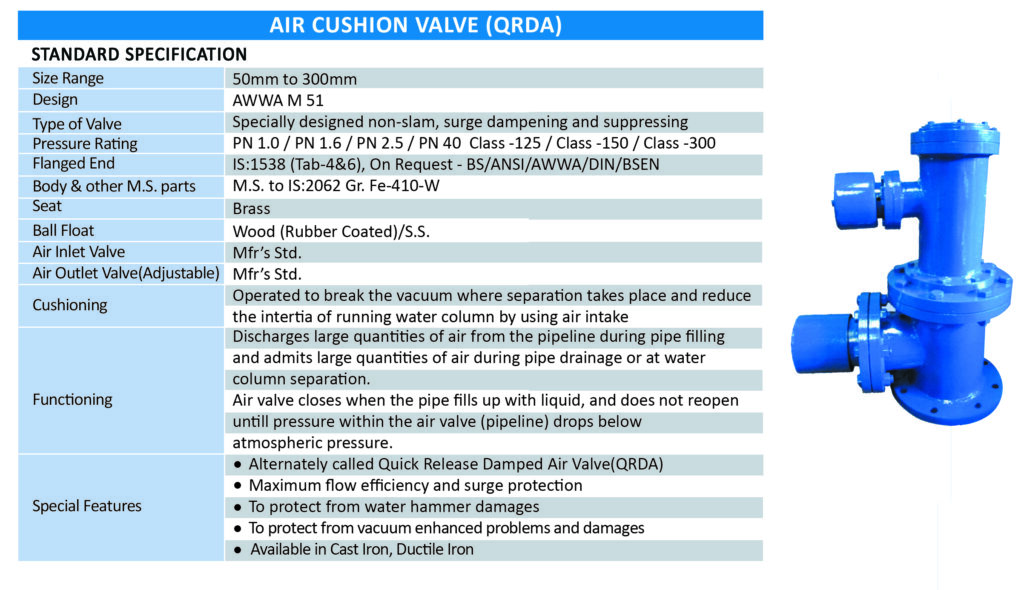

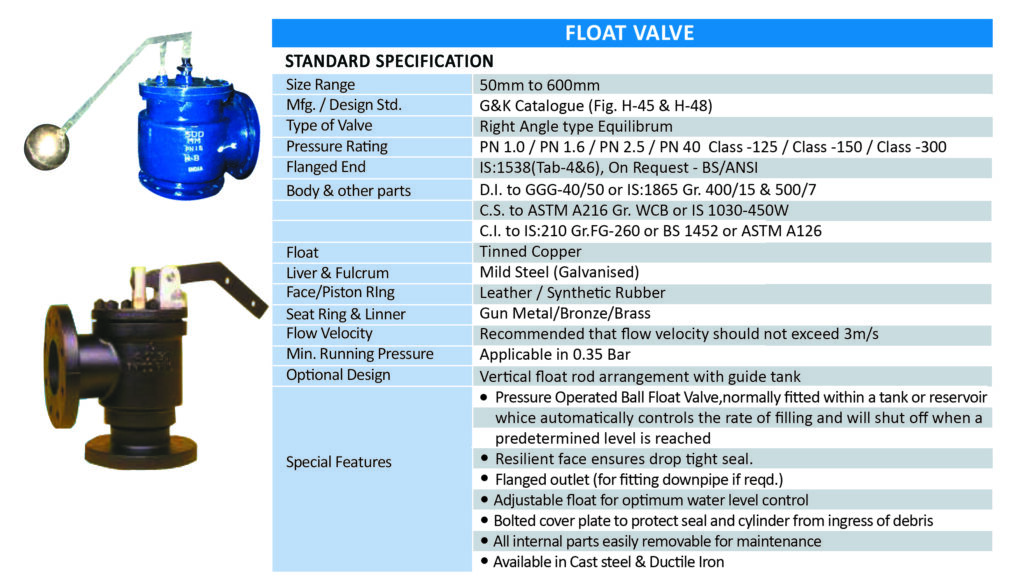

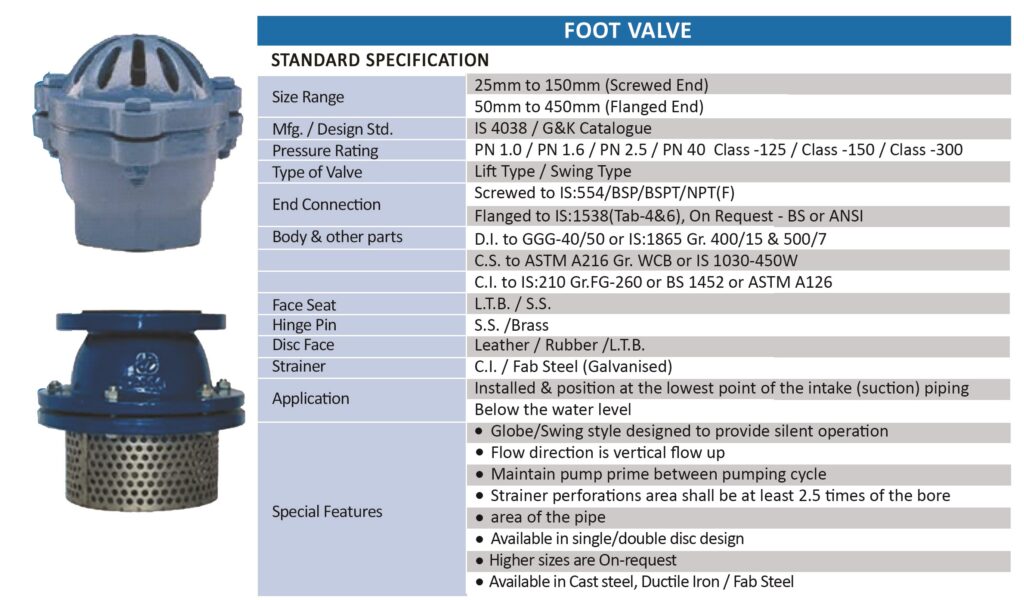

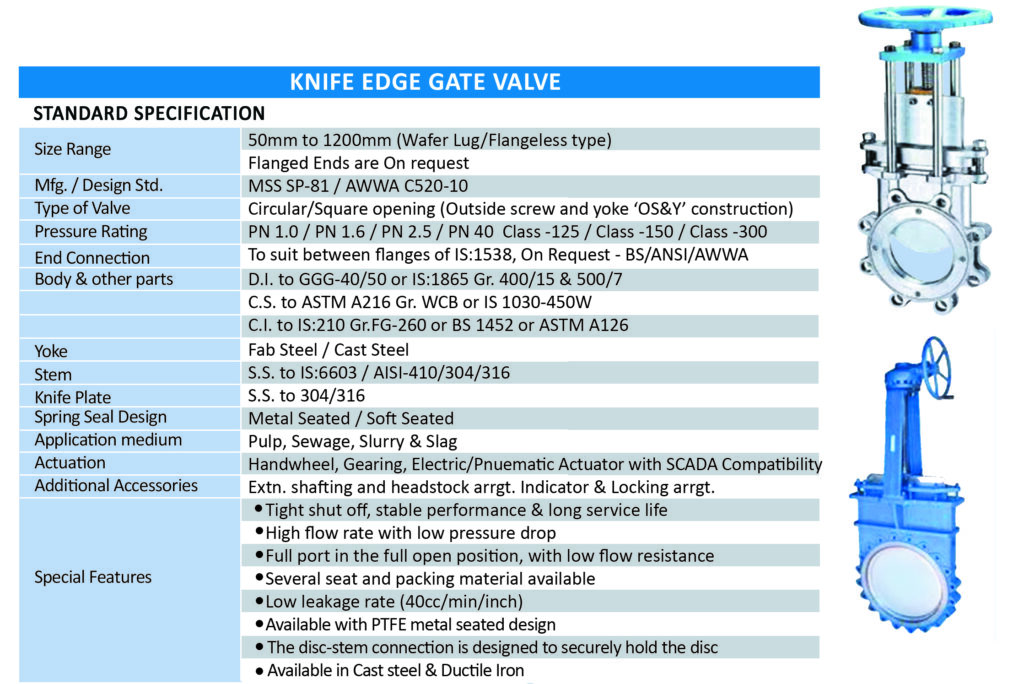

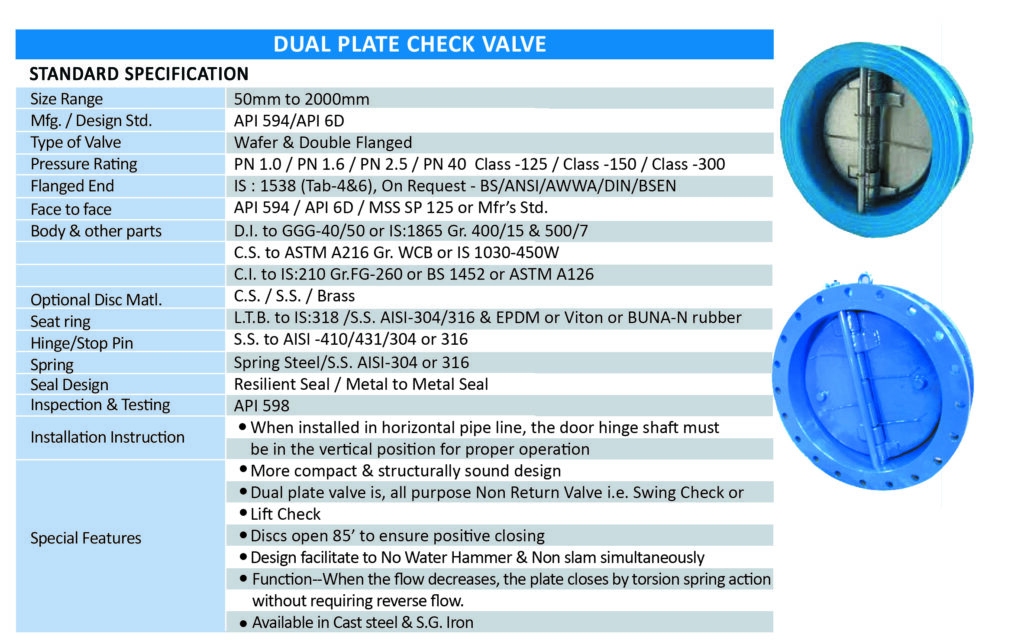

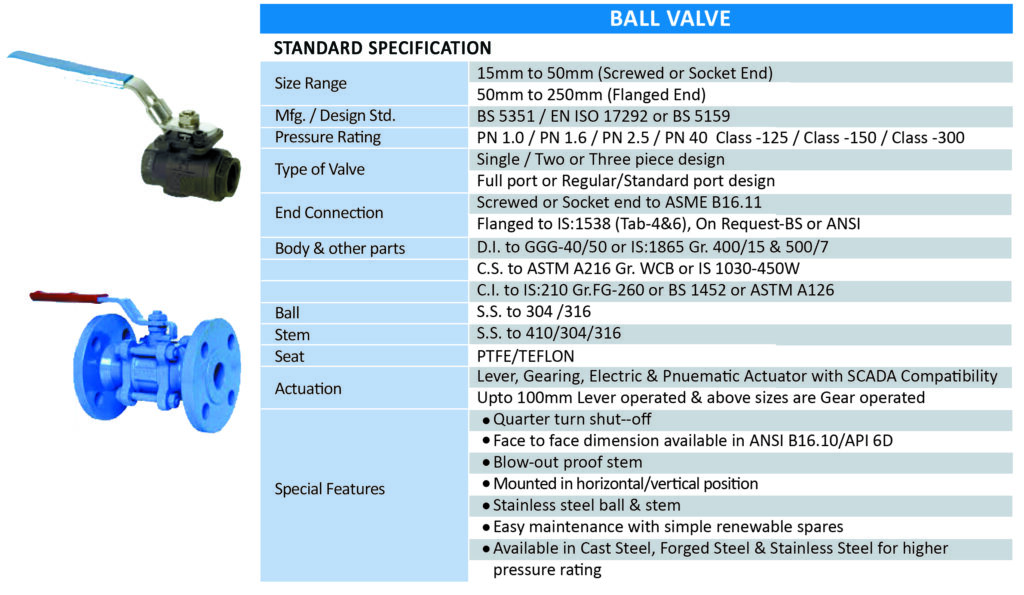

Casting methods allow the manufacturing of parts with complex geometries — shapes that would be difficult or expensive to machine from solid steel. That’s why castings remain popular for parts like housings, valve bodies, heavy-duty supports, frames, components for machinery and industrial equipment.

Versatility across industries:

From industrial valves and pipe fittings (exactly what our casting facility produces) to heavy machinery, infrastructure components, rail and construction equipment — Ductile Iron and steel castings serve many sectors.

Because of these traits, ductile iron castings often strike the sweet spot when you want reliability without overshooting cost — delivering performance that’s “strong enough” for most heavy-duty applications but still economically sensible.

Where Ductile Iron Castings and Steel Castings Make a Real Impact (Use Cases & Applications)

When you think of industrial parts that really matter — where failure is not an option — castings are often behind them. Here are some of the typical areas where Ductile Iron and cast steel castings shine:

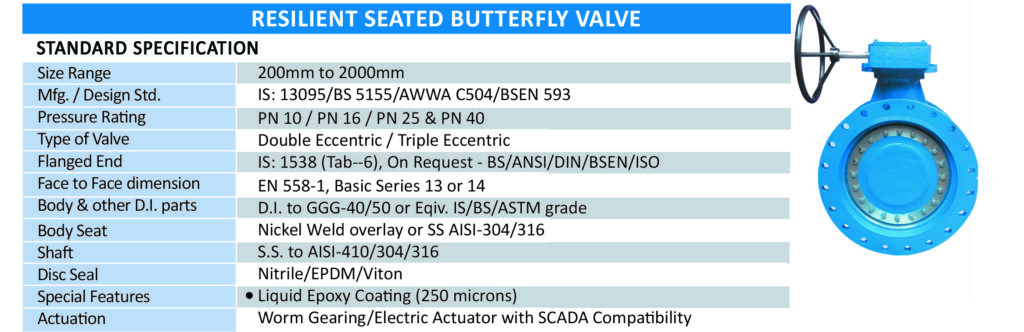

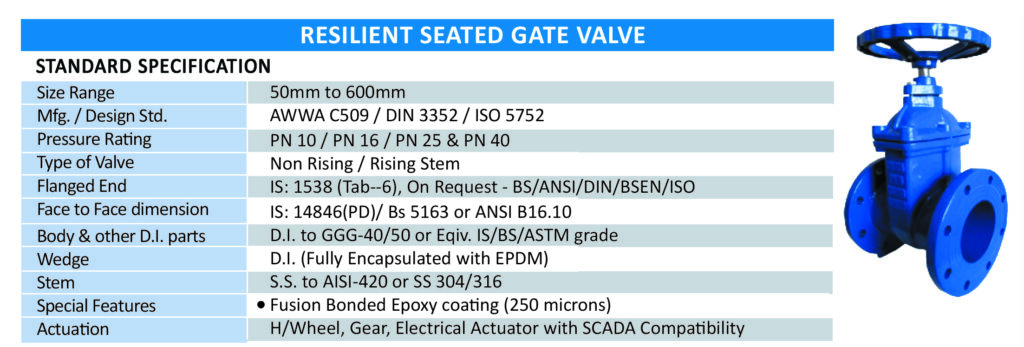

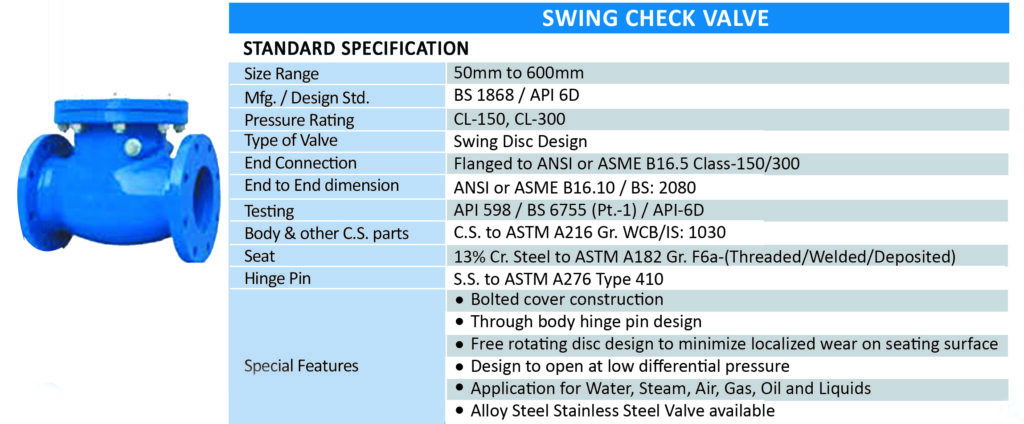

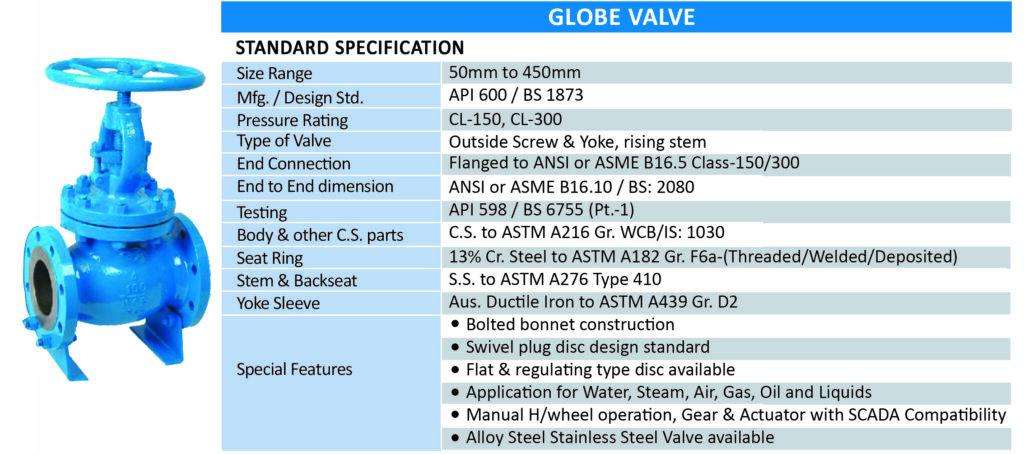

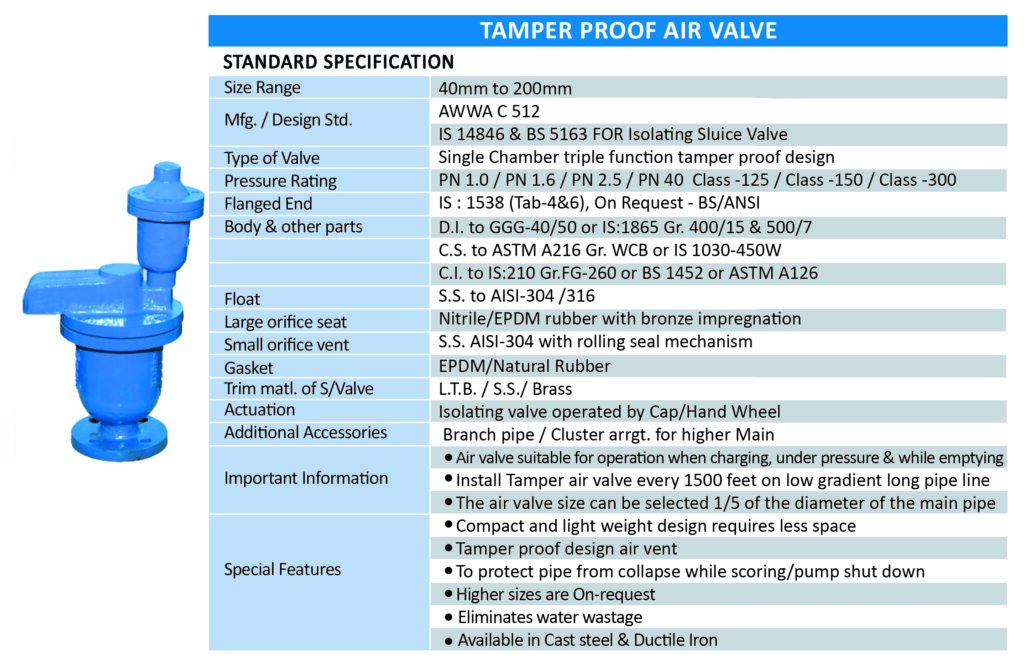

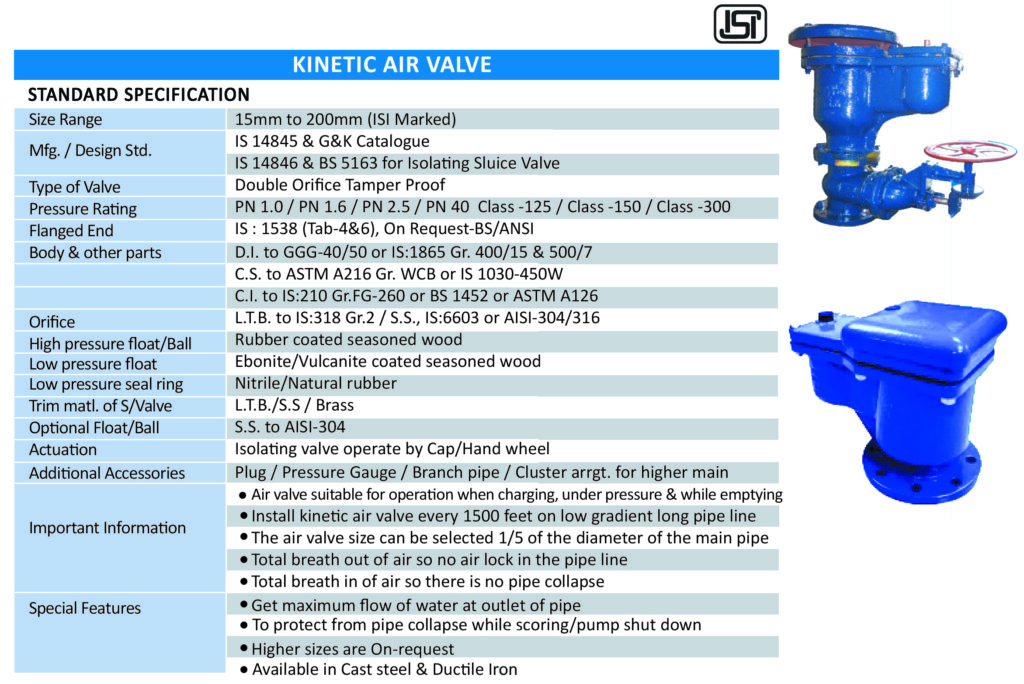

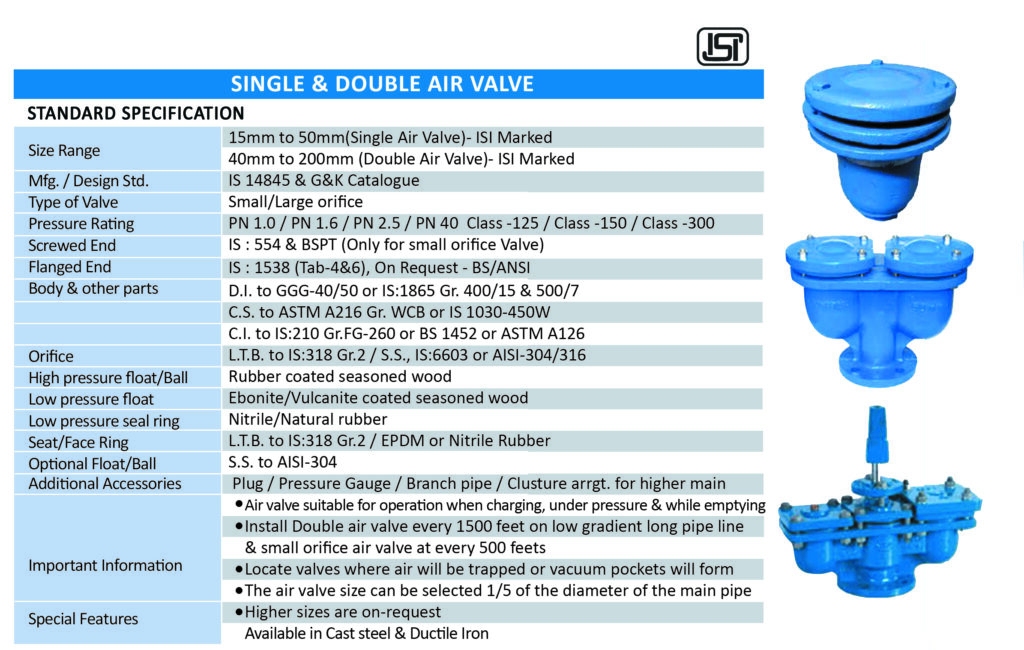

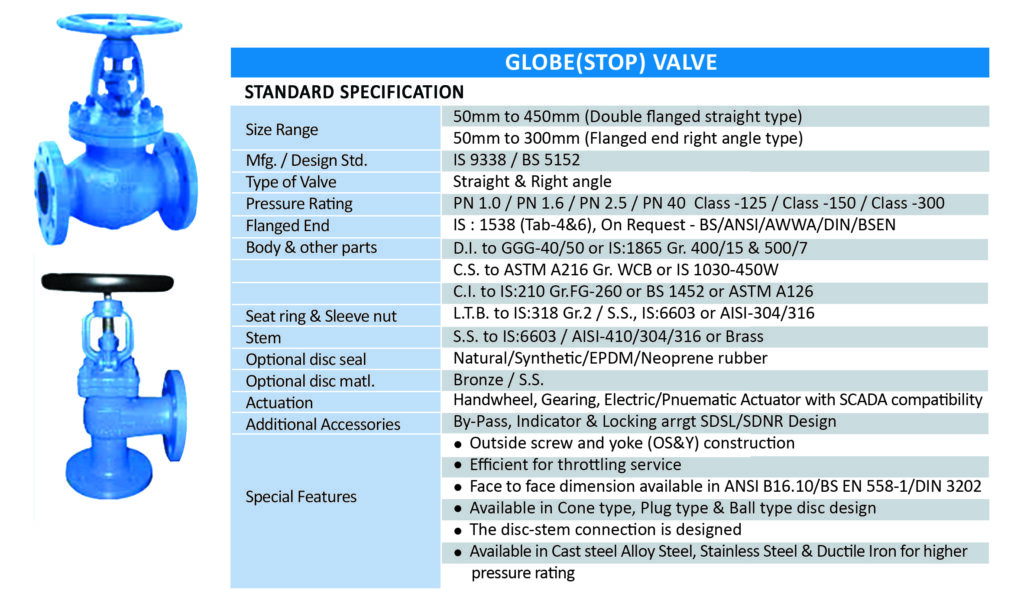

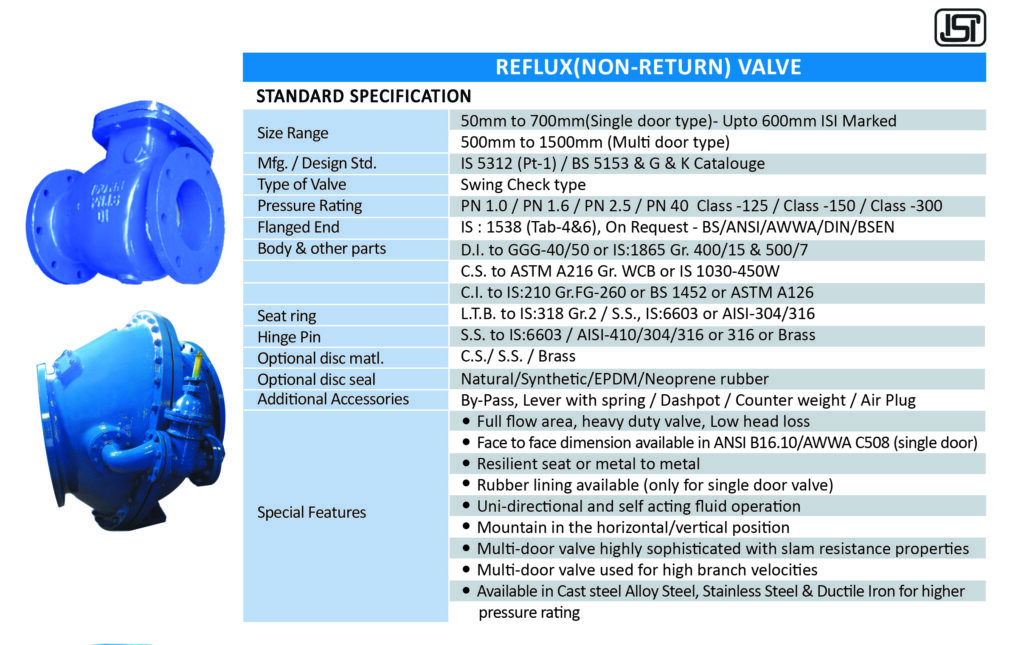

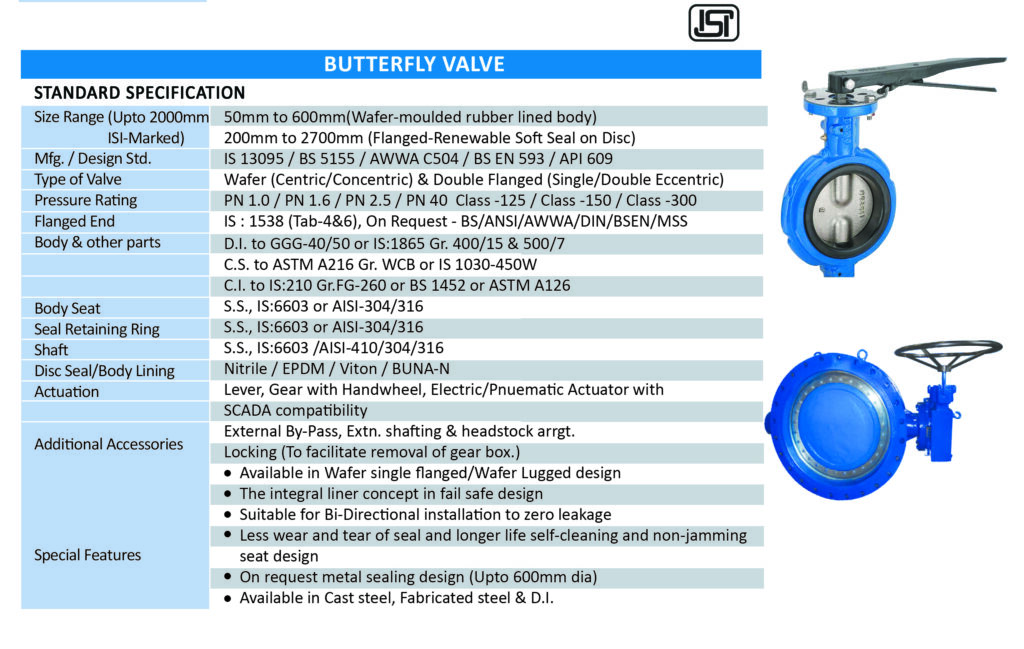

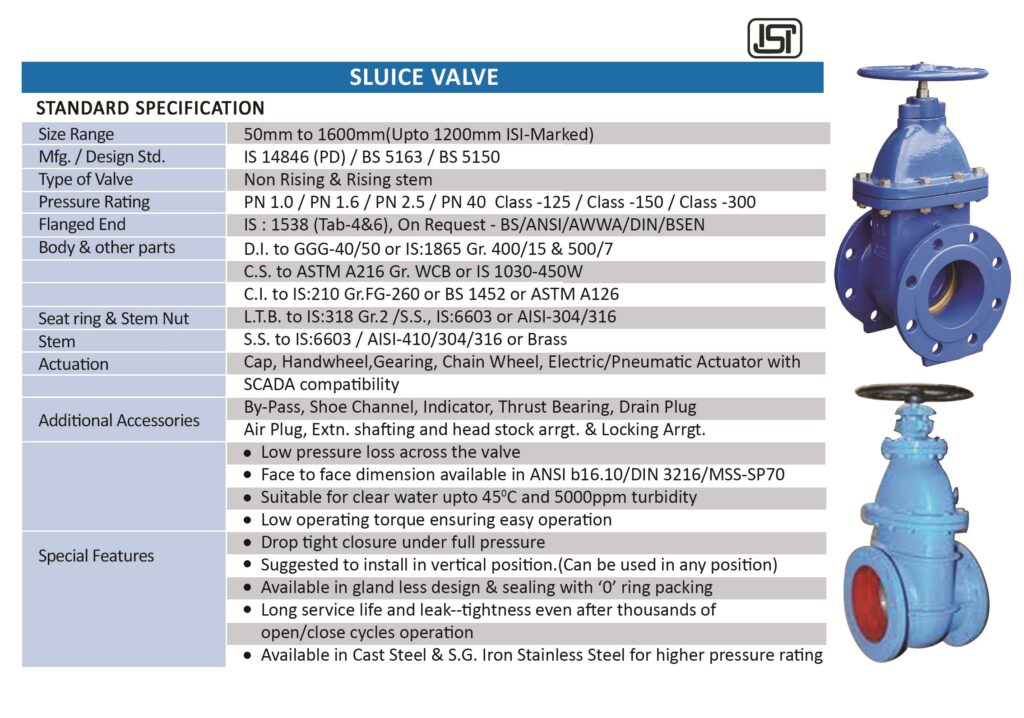

Valves, fittings, pipe components and mechanical spares: Just as our manufacturing facilities supply these parts frequently rely on Ductile Iron or steel castings for reliability under pressure, wear, and frequent use.

Heavy machinery, industrial equipment, and structural components: Frames, supports, housings, machine beds — all benefit from the combination of strength, ductility, and castability that castings offer.

Railway and infrastructure applications: Castings (iron or steel) often go into components requiring high load capacity, resistance to wear and fatigue, and durability under harsh conditions.

Automotive, agriculture, mining and construction equipment: In engines, gear housings, linkages, load-bearing parts — where repeated stress, impact, and long lifetimes matter — castings (especially Ductile Iron or steel) prove their worth.

Why Shree Krishna Industries— and You — Might Prefer Ductile Iron / Steel Castings Over Other Solutions

At our casting facility, we’ve built our foundry and production capabilities to offer a broad range of casting materials — from Ductile Iron to cast carbon steel, alloy steel, stainless steel, even non-ferrous metals — all under one roof.

Here’s why that benefits you:

Flexibility:

We help you choose what truly fits your job — whether you want something budget-friendly and long-lasting or a casting built for serious strength and impact. You get exactly what your application needs, nothing less.

Quality & Compliance:

Because we follow strict ISO standards, you receive castings you can trust. Every step — from melting to inspection — is controlled so you get consistency and peace of mind.

One-stop Convenience:

With our foundry, machining, and fabrication under one roof, you don’t chase multiple vendors. We deliver parts that arrive ready to install, saving you time, effort, and unnecessary rework.

How You Should Choose Between Ductile Iron Castings, Cast Iron Castings/ Cast Steel Castings (What to Keep in Mind)

When you’re specifying or ordering cast components, here are some guidelines to help you decide:

- If you need good strength + toughness + wear resistance at a reasonable cost, and if the part will face static or moderate dynamic loading, go for Ductile Iron Castings.

- If the application involves high pressure, heavy dynamic loads, shock, vibration, or demanding mechanical stress, cast steel castings (carbon or alloy) are often a safer choice.

- If the geometry is complex, or the design involves intricate shapes — casting (whether DI or steel) makes more sense than machining from solid.

- Always consider manufacturing quality, post-casting treatment, machining or finishing — because even the best material can underperform if casting defects, porosity, or poor quality control creep in.

In Conclusion — Casting is More Than “Molten Metal in a Mold”

When you choose castings — whether Ductile Iron , Cast Iron steel Castings, or cast steel — you’re not just buying a metal part. You’re investing in a combination of material science + manufacturing precision + durability + cost-effectiveness.

At Shree Krishna Industries, we understand that. We don’t just supply castings — we deliver power to your infrastructure, confidence to your build, and reliability to your operations. Because when industries run on castings, they run on trust.